Multifunctional grinding tool

A multi-functional, grinding tool technology, applied in the direction of grinding tools, grinding/polishing hand tools, manufacturing tools, etc., can solve troublesome, unsafe, collision and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

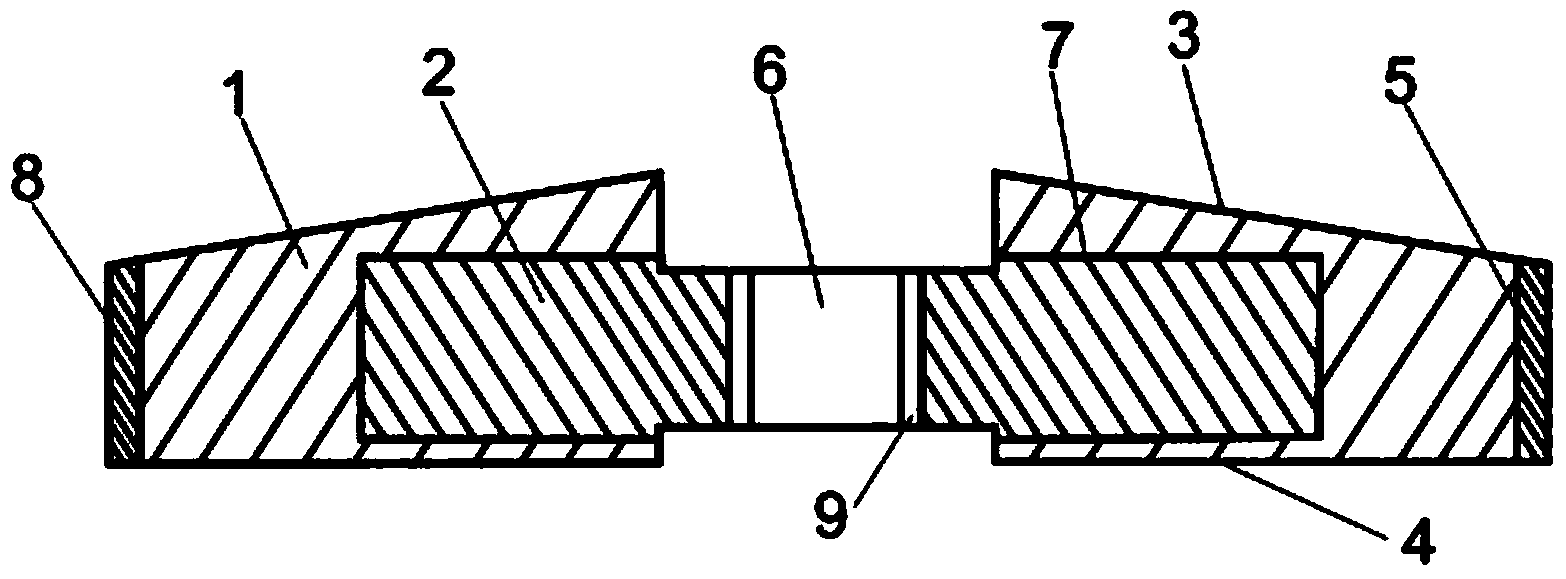

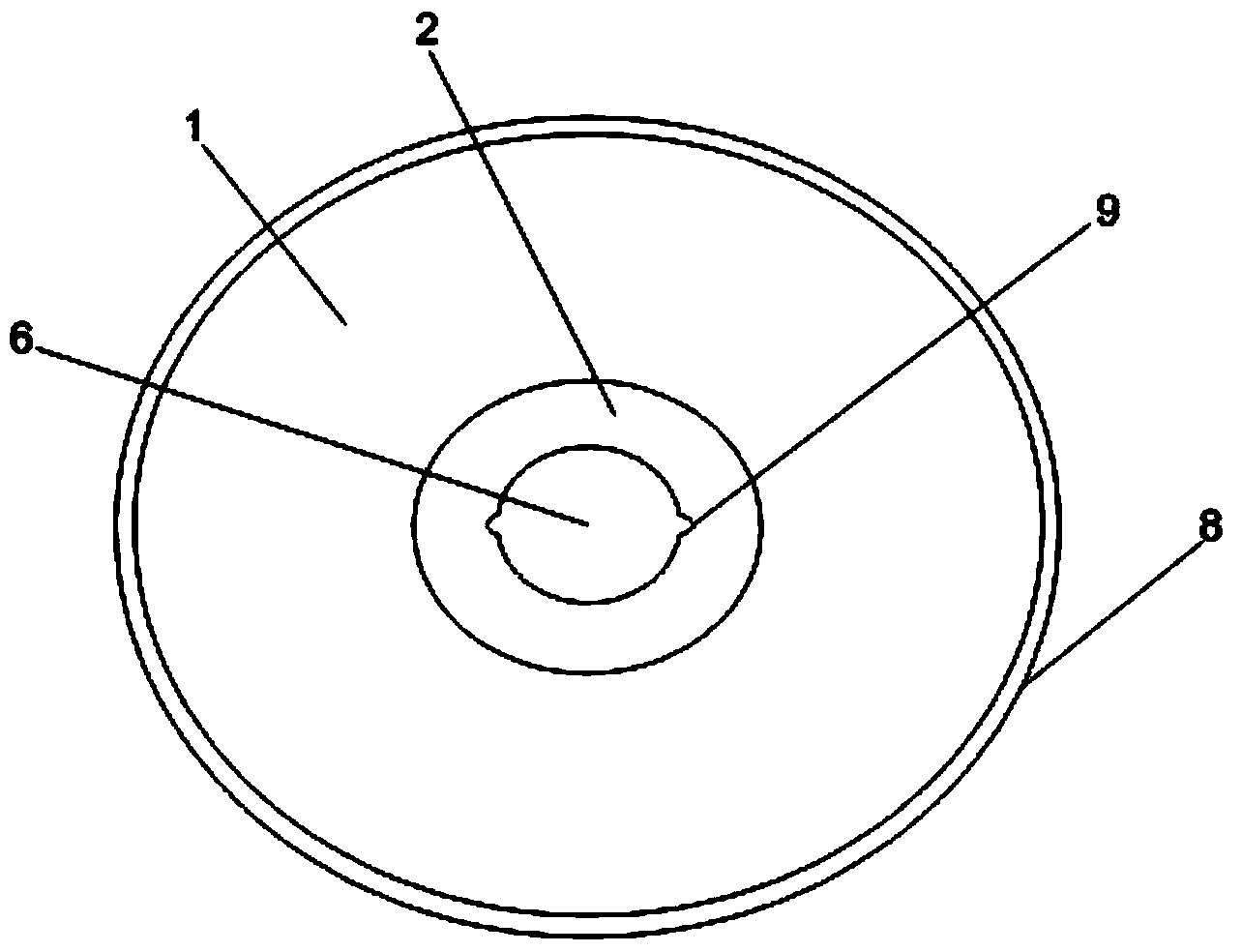

[0019] Such as figure 1 , figure 2 As shown, a multifunctional abrasive tool includes a base body 2 surrounded by a circle of grinding layer 1, the upper surface of the grinding layer 1 is an oblique cone grinding layer 3, and the lower surface is a horizontal grinding layer 4 , the side is a cylindrical side grinding layer 5; the center of the base 2 is provided with a shaft hole 6.

[0020] A portion of the surface of the substrate 2 wrapping the abrasive layer 1 protrudes to form ribs 7 . The ribs 7 can make the matrix 2 more firm when driving the abrasive layer 1 to rotate.

[0021] A detachable gauze layer 8 is provided on the surface of the cylindrical side grinding layer 5 . During grinding, debris is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com