Super-hard material grinding disc and manufacturing method thereof

A technology of superhard material and manufacturing method, which is applied in the direction of manufacturing tools, abrasives, grinding devices, etc., can solve the problems of difficulty in ensuring the quality of superhard material grinding discs, achieve the solution of difficult quality assurance, increase strength, and be simple and easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

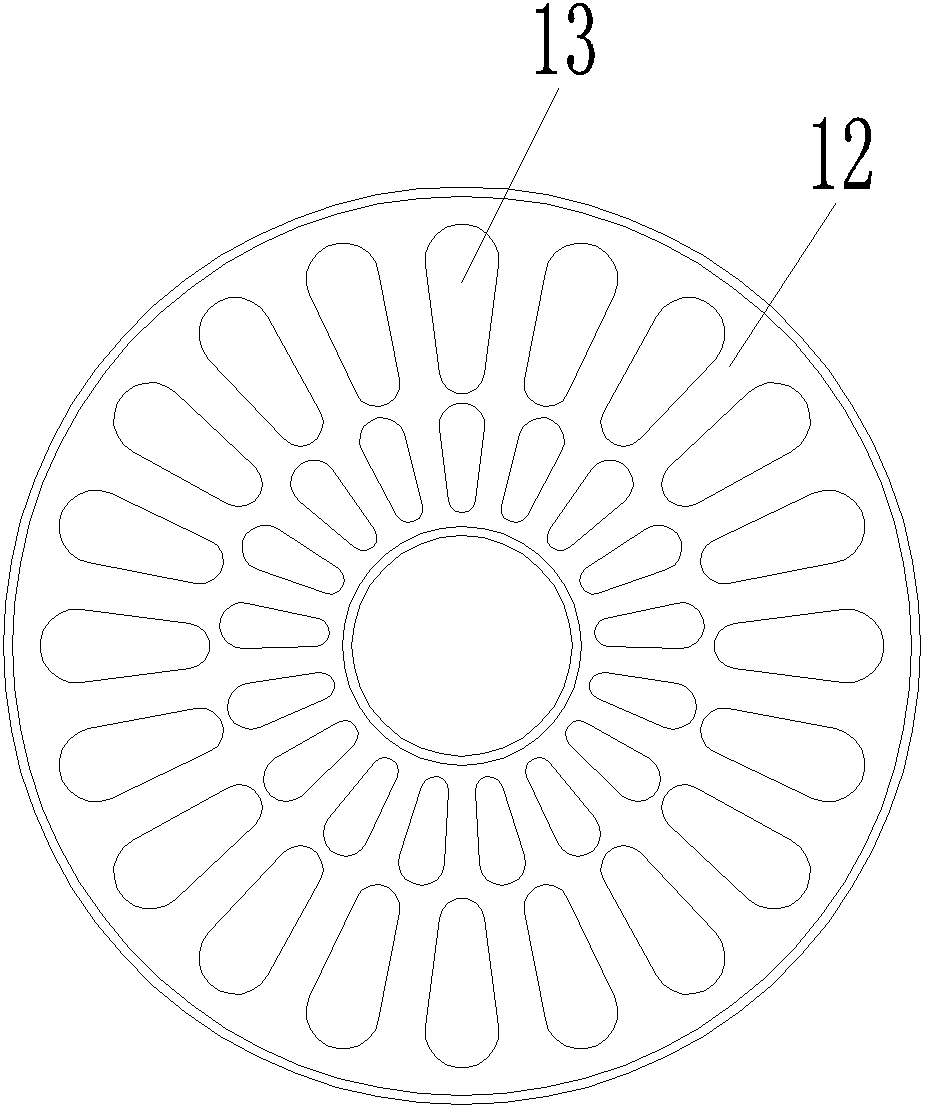

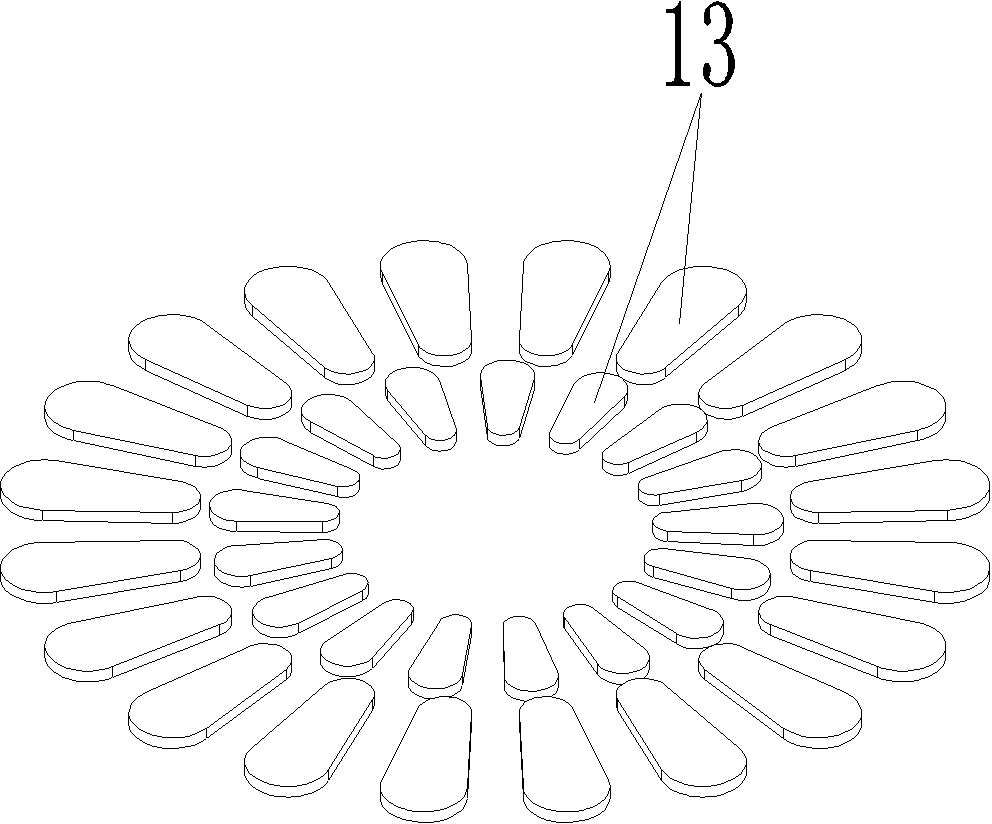

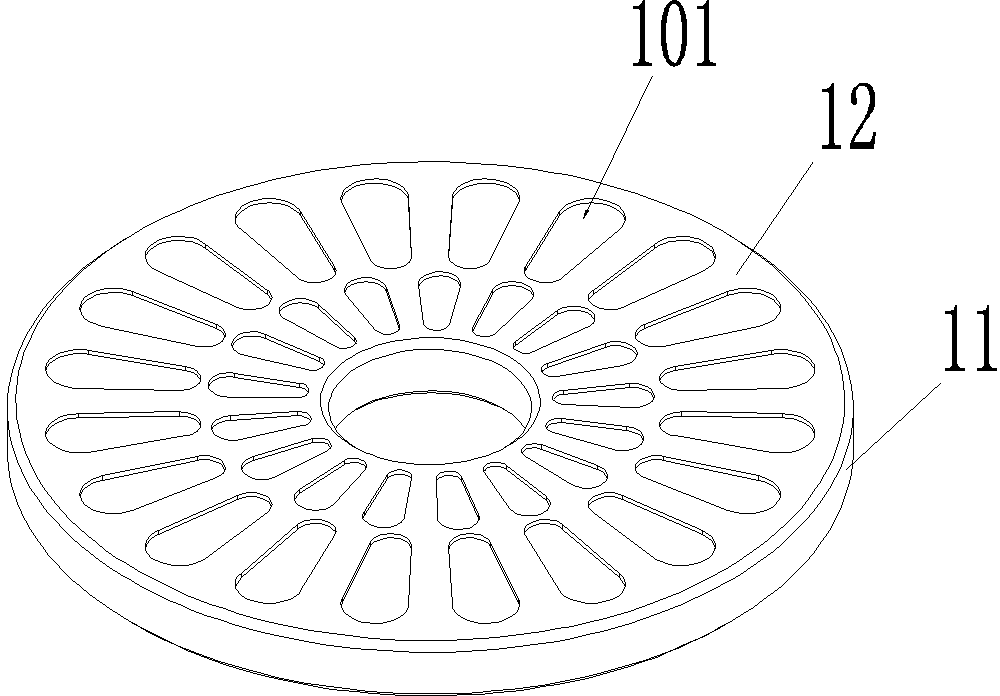

[0026] Examples of abrasive discs of superhard material, such as Figure 1-4 As shown, the superhard material grinding disc includes a grinding disc base 11 , a filling layer 12 and abrasive blocks 13 .

[0027] The overall profile of the disc substrate 11 is disc-shaped, and the side for installing the abrasive block 13 is provided with a positioning groove 101, which corresponds to the abrasive block 13 one by one, and is used for positioning the installation of the abrasive block 13.

[0028] The edges of the two ends of the abrasive block 13 in the radial direction of the grinding disc base 11 are arc-shaped respectively. In addition, the abrasive block 13 gradually narrows from one end close to the outer ring of the grinding disc base 11 to the other end. In this embodiment, the corresponding ends of the abrasive block 13 The arcs formed are all circular arcs, and the arcs at the corresponding two ends of the abrasive block 13 are oppositely arranged. In general, in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com