Brake control unit for railway vehicle

A brake control and rail vehicle technology, which is applied in the field of vehicle brake control systems, can solve problems such as the inability to uniformly distribute the braking force of the entire vehicle, the inability to distribute the braking force in a balanced manner, and the loss of braking force distribution of the entire vehicle. Safety, improved safety level, improved equipment and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described in conjunction with the accompanying drawings.

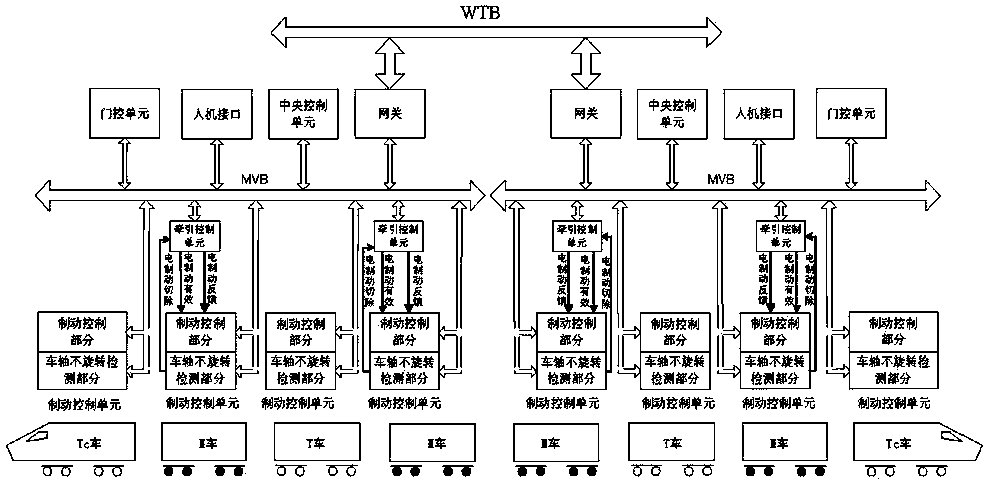

[0024] The overall structure distribution of the control unit of the present invention is as follows: figure 1 As shown, including the brake control part and the non-rotation detection part of the axle, these two parts are completely independent electrically. The brake control part mainly includes the air brake control unit, wheel slide protection unit, MVB network communication and serial communication, and the axle non-rotation detection part mainly includes the axle speed abnormal detection unit, MVB network communication and serial communication.

[0025] The brake control part has the function of brake force control. The braking force is calculated according to the vehicle load and speed information, and the braking force is managed and distributed through the MVB network. The motor vehicle applies for electric braking force to the traction c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com