Device for winding and unwinding two-dimensional roll material

A flat tape and strip technology, applied in the direction of winding strips, paving, transportation and packaging, etc., can solve problems such as troublesome manufacturing process, achieve simplified work, high laying and collecting accuracy, winding and unwinding process improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

[0032] In the drawings, components that are the same or have the same function are represented by the same component symbols, and the described components will not be described repeatedly when they appear again.

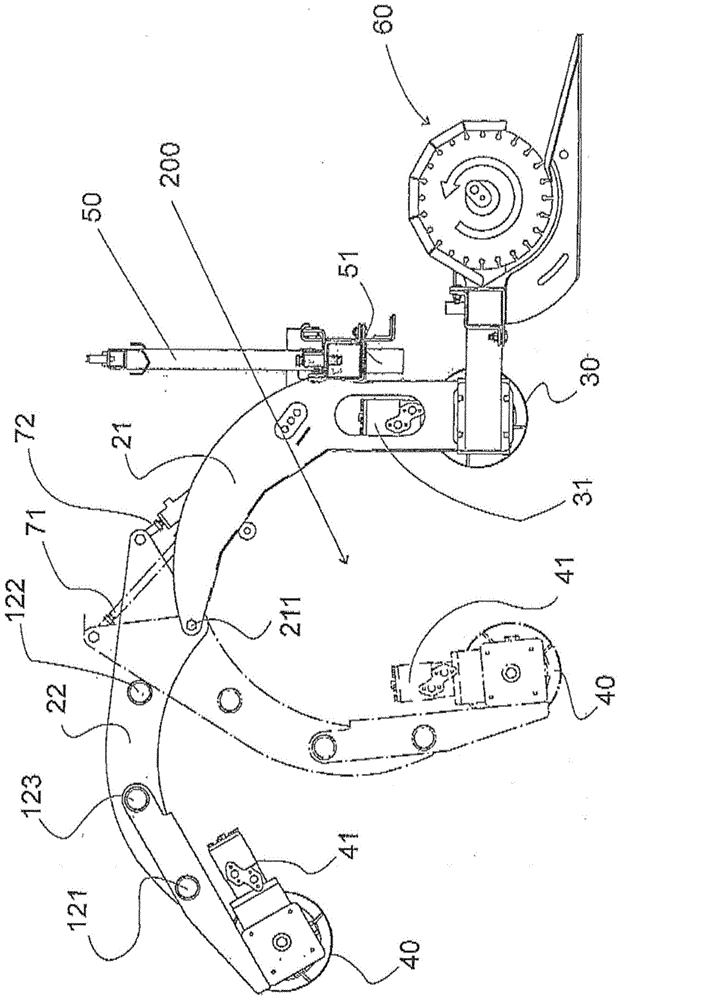

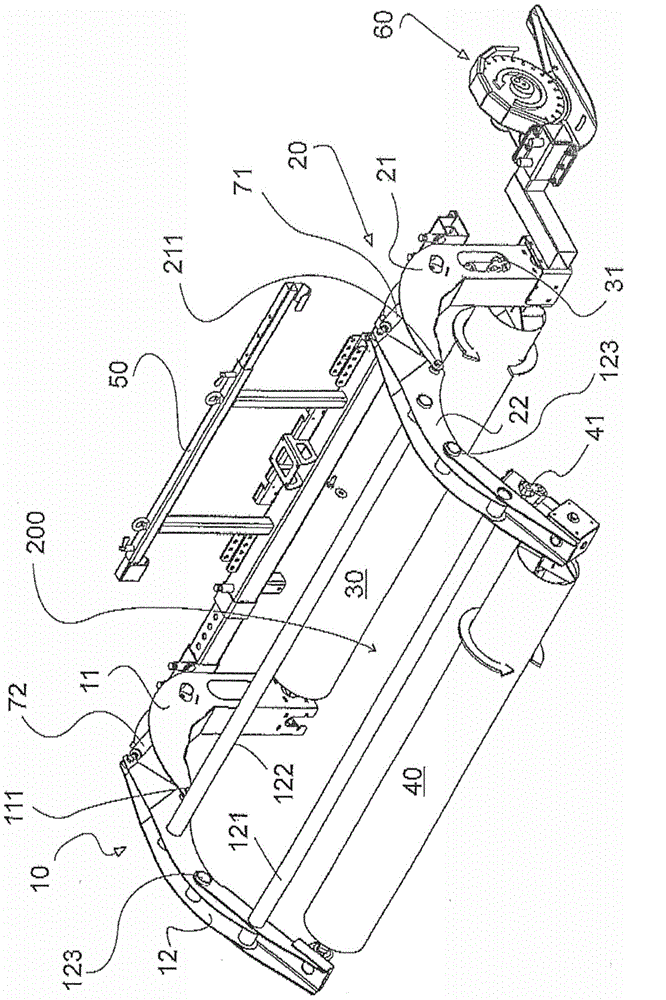

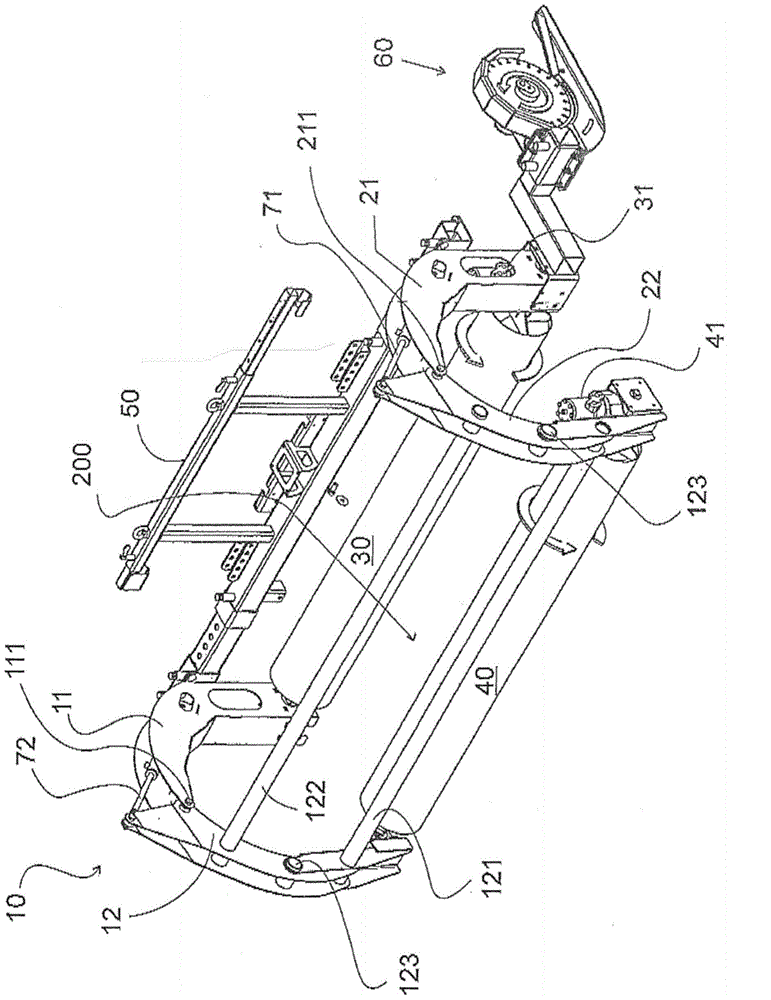

[0033] figure 1 It is a side view of an embodiment of the flat strip winding and unwinding device of the present invention. The device according to the invention consists of at least one forceps 10 , 20 . The pliers 20 are composed of a fixed grasping assembly or pliers assembly 21 and a movable grasping assembly or pliers assembly 22 . The words pliers assembly and grasping assembly are synonymous. Hence the following references to the gripper assembly and the pliers assembly refer to the same assembly on the device. It can be seen from FIG. 1 that the fixed pliers assembly 21 and the movable pliers assembly 22 are movably conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com