Front fly formation assisting tool

An auxiliary tooling and placket technology, applied in textiles and papermaking, cloth feeding mechanism, sewing equipment, etc., can solve the problems of uneven product quality, inconsistent final effect, long sewing cycle, etc., and reduce the difficulty and strength of operation , Improving the molding effect and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below through specific examples.

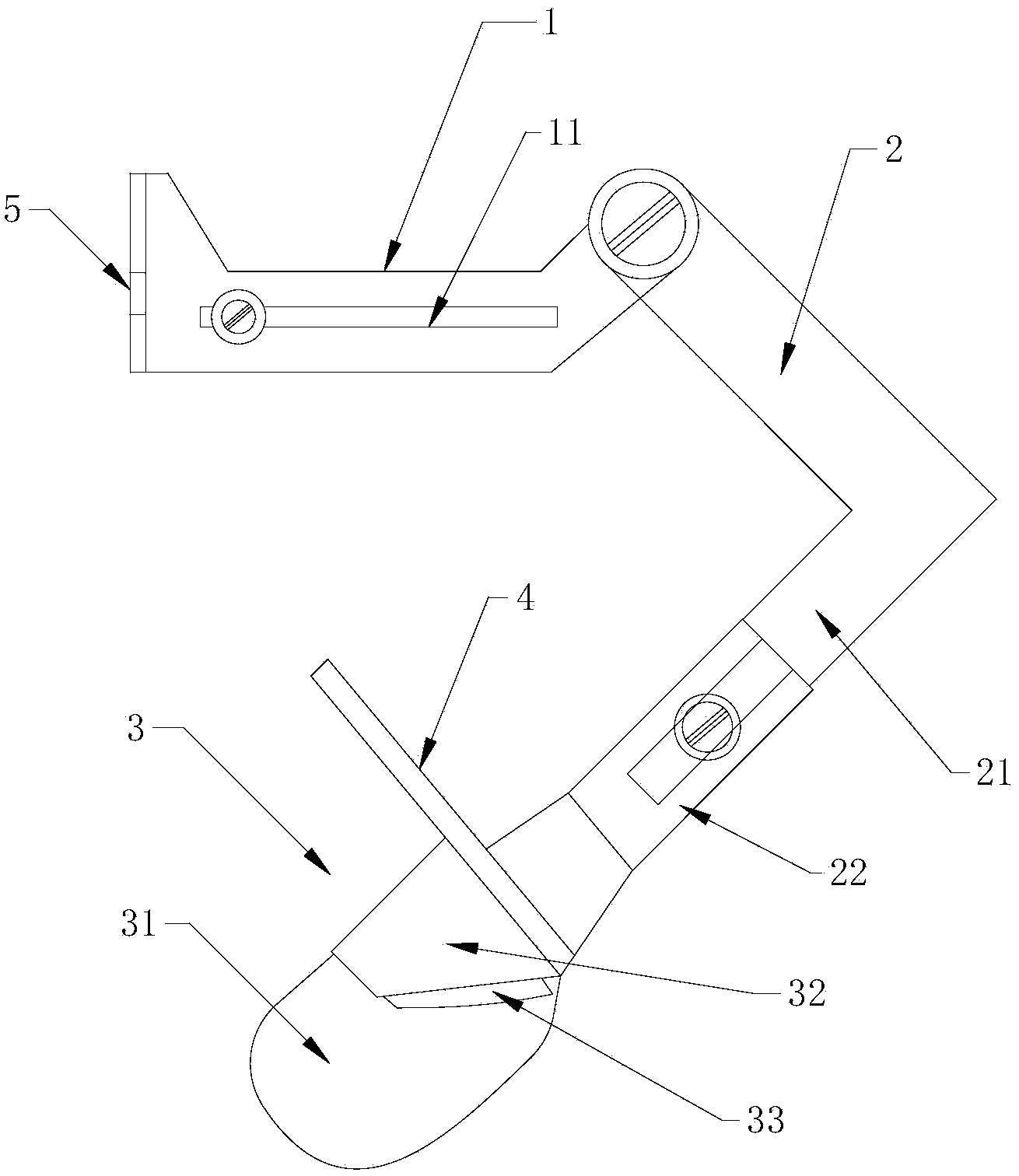

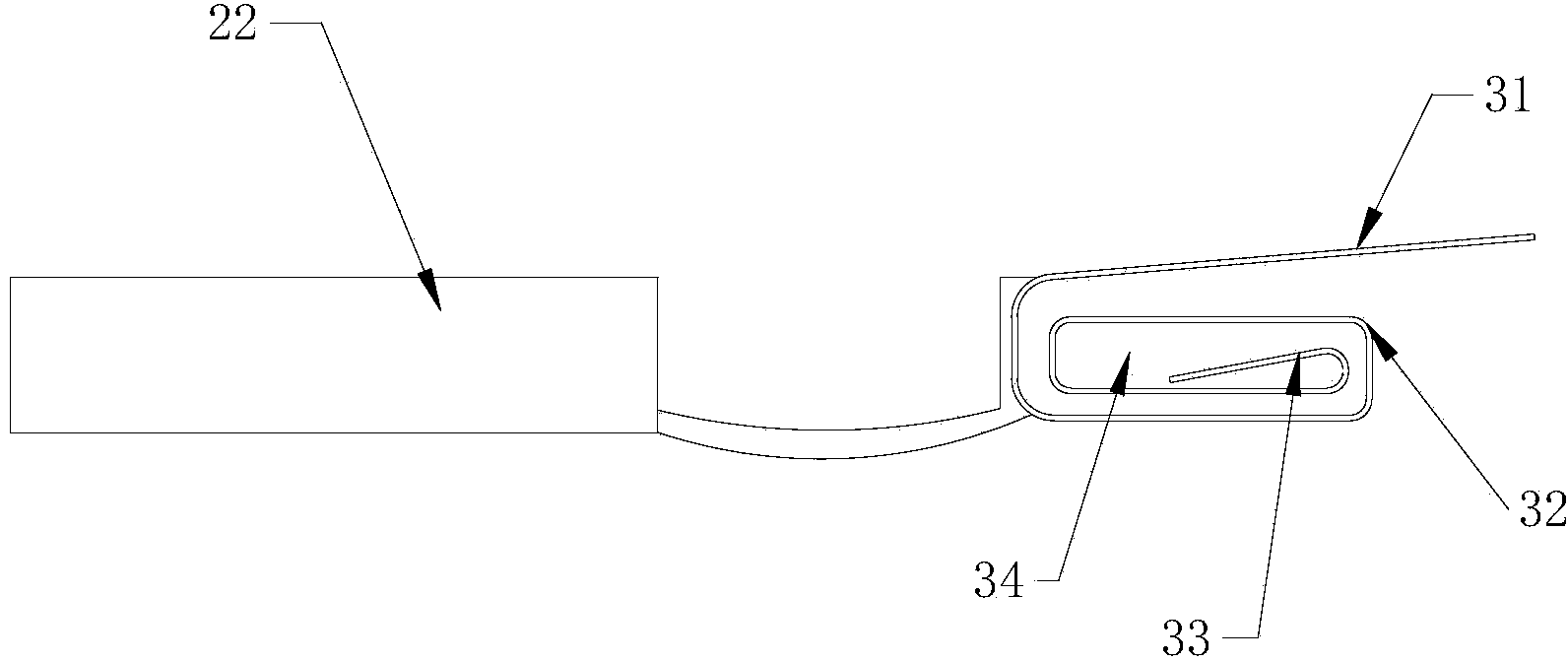

[0018] Such as figure 1 As shown in the figure, an auxiliary tool for forming a placket includes a positioning rod 1 fixed on the working platform of the sewing machine, a rotating rod 2 mounted on the positioning rod 1, and a free end of the rotating rod 2 is installed for folding the edge of the fabric into The forming mold 3 of the placket, the forming die 3 includes a laminating plate 31 attached to the working platform, and a placket forming channel 34 made of a thin plate on the upper side of the laminating plate 31, which is curved from the outside to the inside, and the placket is formed The outer side of the channel 34 is open, and the rotating rod 2 is provided with a locking structure that cooperates with the positioning rod 1 . When it is not necessary to carry out the molding of the placket, the turning bar 2 can be rotated so that the molding die 3 is kept away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com