Ballast leveling mechanism for leveling ballast bed

A ballast and ballast bed technology, applied in the field of railway maintenance operation equipment, can solve the problems of slow movement of ballast, low operation efficiency, accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

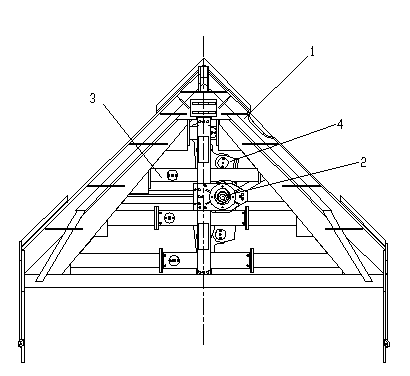

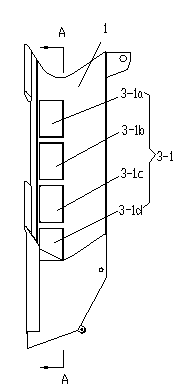

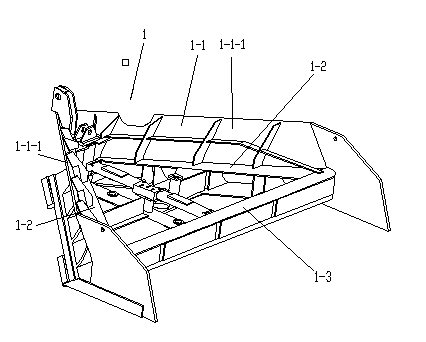

[0025] Such as Figure 1~12 As shown, a ballast leveling mechanism for ballast bed leveling includes a ballast plow frame 1, an eccentric shaft part 2, a beam part 3 and a connecting rod part 4, and the ballast plow frame 1 includes a mouldboard 1-1. The moldboard 1-1 is composed of two plow blades 1-1-1 obliquely intersecting and fixed. The outer surface of the plow blade 1-1-1 has a concave arc surface, and each plow blade 1-1-1 Both have the first hammer hole 1-1-1-1, the positions of the corresponding first hammer holes 1-1-1-1 on the two plow blades 1-1-1 are corresponding, and the flat ballast plow frame 1 It also includes two hammer hole plates 1-2 and a middle frame 1-3, and the two hammer hole plates 1-2 are respectively fixed on the inner sides of corresponding plow blades 1-1-1, and each hammer hole plate 1-2 Each has a second hammer hole 1-2-4, the second hammer hole 1-2-4 corresponds to the position of the corresponding first hammer hole 1-1-1-1 on the plow blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com