Self-propelled high pressure water jet drill

A high-pressure water jet, self-propelled technology, applied in the direction of liquid/gas jet drilling, construction, etc., can solve the problems of high cost and poor economy of sidetracking horizontal well technology, so as to expand the diameter of the wellbore and increase the rock breaking speed , Strengthen the effect of rock breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the drawings. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

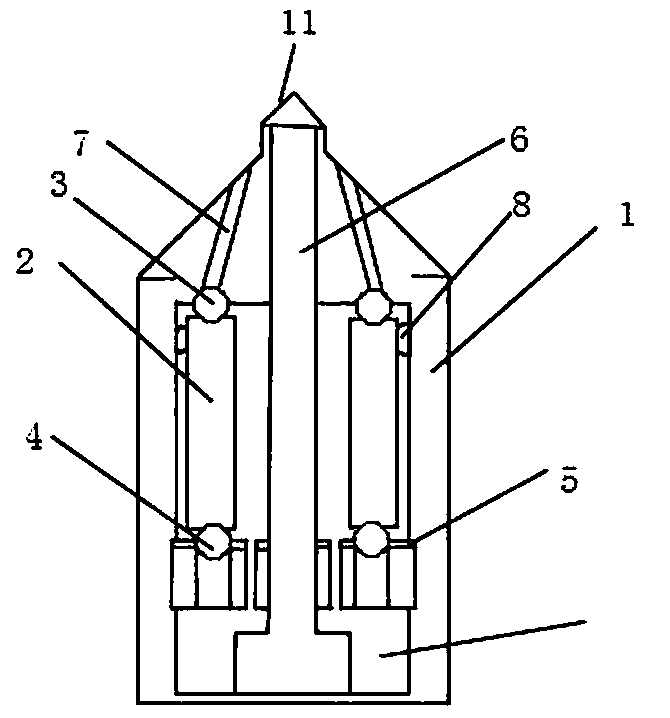

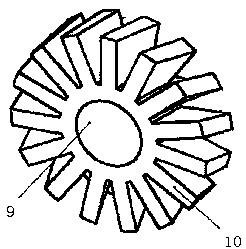

[0015] Such as figure 1 with 2 As shown, this embodiment provides a self-advancing high-pressure water jet drill bit, which mainly includes a bit body 1, a turbine rotor 2, an upper wear-resistant steel ball 3, a lower wear-resistant steel ball 4, a baffle 5, and a blind hollow center The shaft 6 serves as a support. The blind hollow shaft 6 has an annular water outlet. The front end of the blind hollow shaft 6 is connected to the front end of the drill body 1. The drill body 1 is provided with a forward nozzle 7 and a rear nozzle 8; the left and right sides of the blind hollow shaft 6 The turbine rotor 2 is installed symmetrically on the side. The upper and lower ends of the turbine rotor 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com