Vertical air shaft double-door type explosion-proof system

An anti-explosion system and vertical air shaft technology, which is applied in mine/tunnel ventilation, mining equipment, mining equipment, etc., can solve the problems of air flow short circuit, low anti-explosion ability, accident expansion, etc., and achieve reduced sealing difficulty and high anti-explosion performance and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

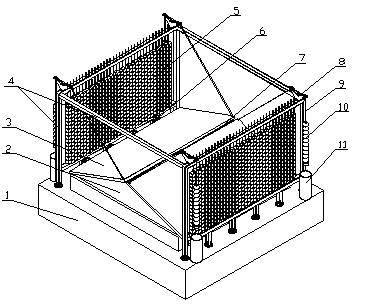

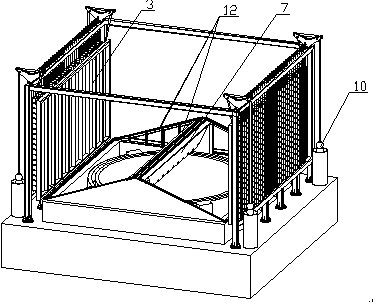

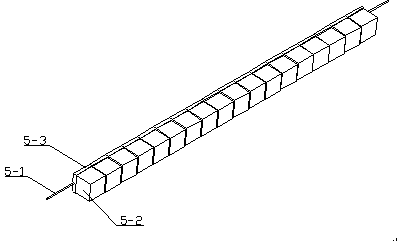

[0034] A double-door explosion-proof system for vertical wind shafts, such as figure 1 As shown, it is mainly composed of gable body 2, door body 3, buffer frame 4, flexible buffer wall 5, door shaft hinge 6, support beam 7, pulley rack 8, steel wire rope 9, variable mass counterweight 10, etc. The gable body 2 is a triangular steel structure wall, or a steel-concrete cast wall, which is used to support the door body 3, and sealing strips 12 are laid on the slopes on both sides. The door body 3 is made up of a door body frame and a door panel. The door body 3 is installed on the buffer frame 4 through the door shaft hinge 6, as Figure 5 As shown, a flexible buffer sleeve 6-2 is provided between the shaft seat 6-1 and the bearing bush 6-3 of the door shaft hinge 6, and the buffer frame 4 is composed of 6 beams, 4 long columns, and several short colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com