Pre-tightening force measurement device of high-strength bolt

A measuring device and technology of high-strength bolts, applied to measuring devices, measuring torque/torsion force, measuring force and other directions during tightening, can solve the problem of high-strength bolt pre-tightening force loss, unable to monitor pre-tightening force loss, and no simple and effective bolts and other problems, to achieve the effect of convenient use, accurate measurement and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

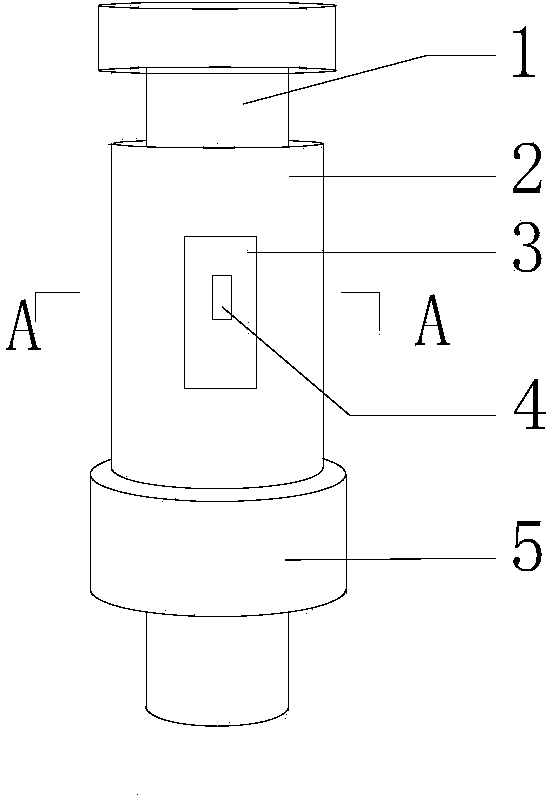

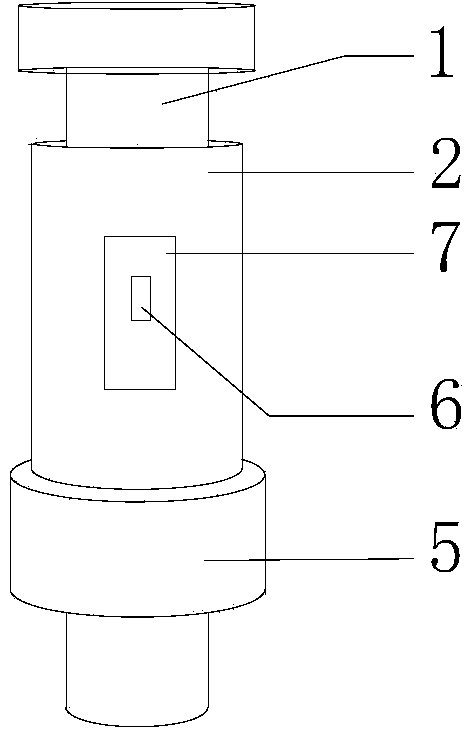

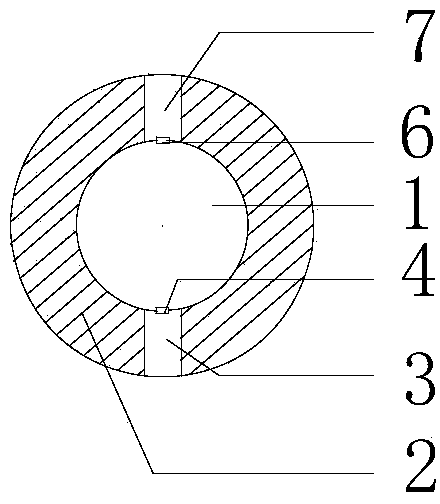

[0013] The technical solution of the present invention will be further described below with reference to the accompanying drawings.

[0014] control Figure 1-3 , a high-strength measuring bolt pre-tightening force device, including a first strain gauge 4, a second strain gauge 6 and a rigid sleeve 2. The rigid sleeve 2 is provided with a first hole 3 and a second hole 7, the rigid sleeve 2 is placed outside the screw 1, the first strain gauge 4 and the second strain gauge 6 are attached to the surface of the screw 1, and the outer With an epoxy resin protective layer, the first strain gauge 4 and the second strain gauge 6 are symmetrically distributed on both sides of the screw 1, the first hole 3 of the rigid sleeve 2 corresponds to the position of the first strain gauge 4, and the first hole 3 of the rigid sleeve 2 corresponds to the position of the first strain gauge 4. The second hole 7 corresponds to the position of the second strain gauge 6 , and the nut 5 tightens the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com