Automatic calibrating device and method used for automobile sideslip testing table

A verification device and test bench technology, applied in wheel testing and other directions, can solve the problems of difficult reliability, estimation error, low manual detection efficiency, etc., and achieve the effects of improving measurement stability, reducing travel error, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the specification and accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

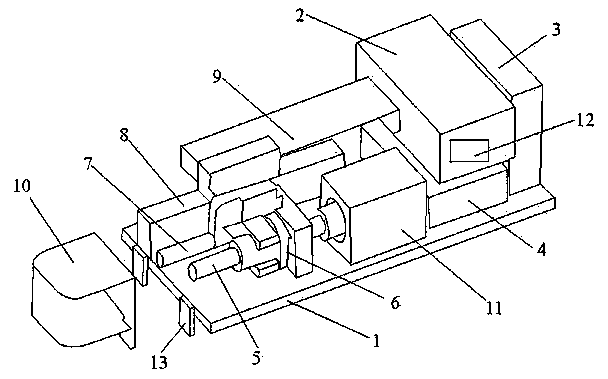

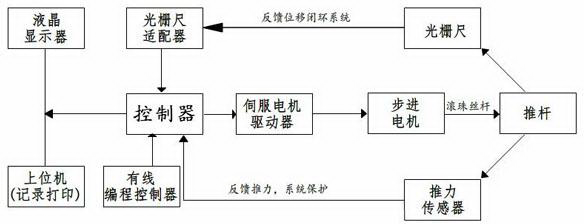

[0024] Such as figure 1 As shown, the automatic verification device for automobile sideslip test bench of the present invention includes a base 1, on which a controller 2, a grating adapter 3, a servo motor driver 4, a stepping motor 11, a screw seat 6. Ball screw 5, push rod 7, grating ruler 8, thrust sensor 9 and electromagnetic meter base 10, grating ruler 8 is installed on one side of push rod 7, and connected with controller 2 through grating adapter 3, grating ruler 8 Collect the displacement of the side slide plate to the controller 2, the controller 2 is connected with the stepper motor 11 through the servo motor driver 4, the stepper motor 11 is fixed on the base, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com