Parallel test system and testing method thereof

A test system and wafer carrying technology, applied in the direction of semiconductor/solid-state device testing/measurement, single semiconductor device testing, etc., can solve problems such as body contact with moving knobs, wafer carrier plate movement, probe card damage, etc. achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

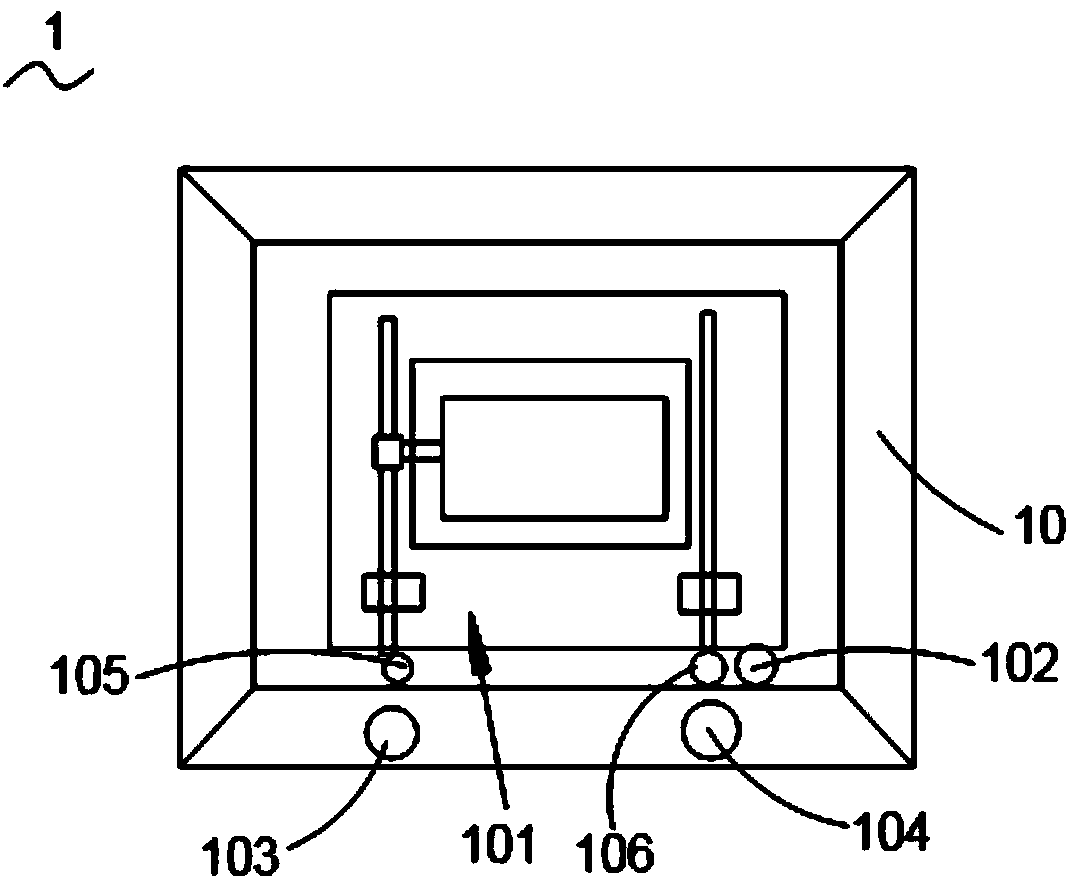

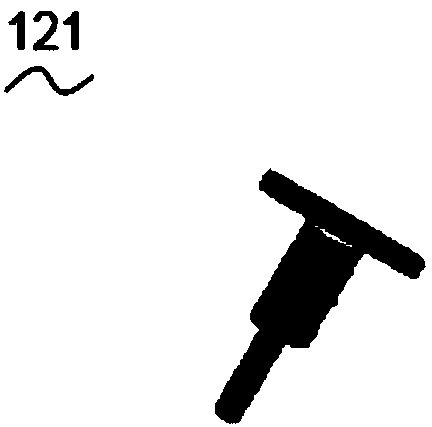

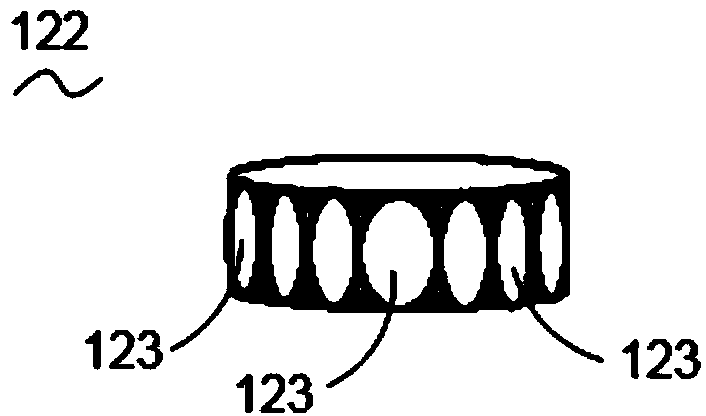

[0020] see Figure 1 ~ Figure 3 , figure 1 Shown is a schematic structural diagram of the parallel testing system of the present invention. Figure 2(a) ~ Figure 2(b) Shown is a schematic structural diagram of the locking component of the parallel testing system of the present invention. image 3 Shown is a cross-sectional view of the parallel testing system of the present invention. The parallel test system 1 includes: a housing 10, the housing 10 encloses and forms an accommodating space 101, and the wafer carrying platform lifting knob 102 is arranged at intervals on the housing 10, and the wafer carrying platform moves left and right Knob 103, knob 104 for moving the wafer carrying platform back and forth; wafer carrying tray 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com