Plane turnover multi-point leveling device and method

A leveling device, multi-point technology, applied in the direction of control using feedback, can solve the problems of many virtual legs in the coupling plane, poor horizontal stability, mutual coupling, etc., to improve accuracy and efficiency, and achieve the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

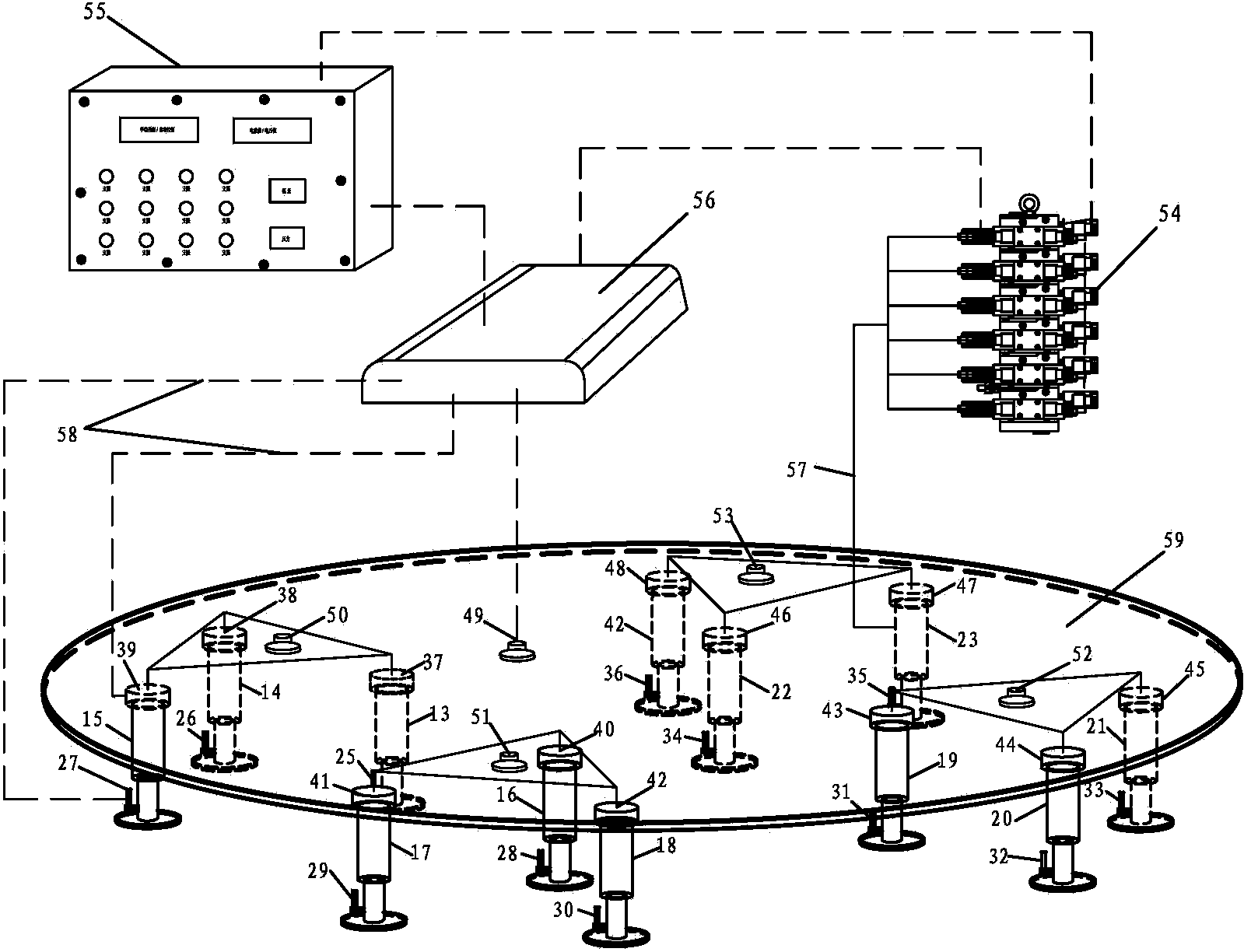

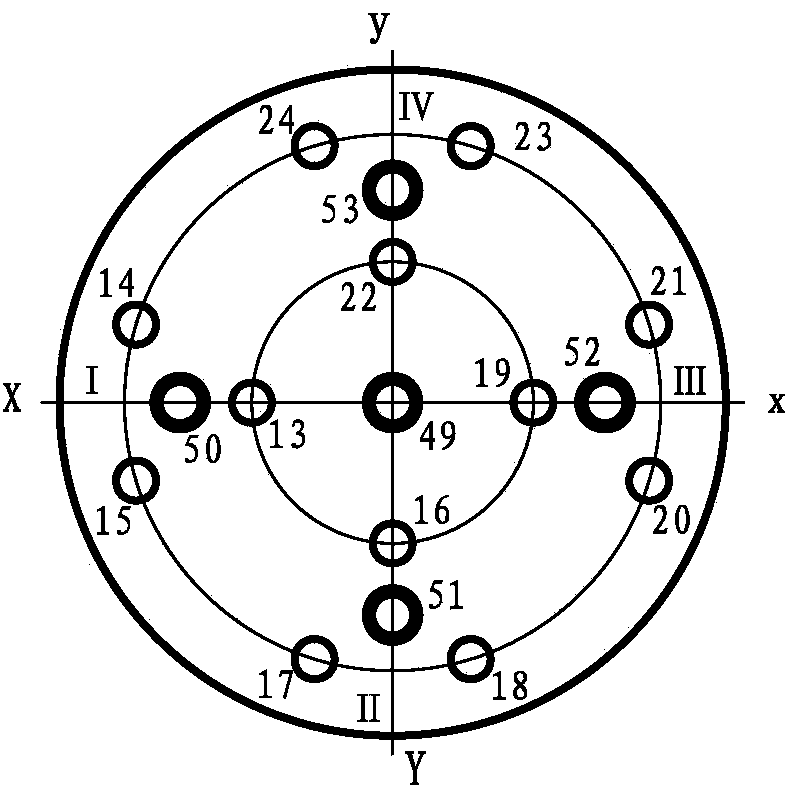

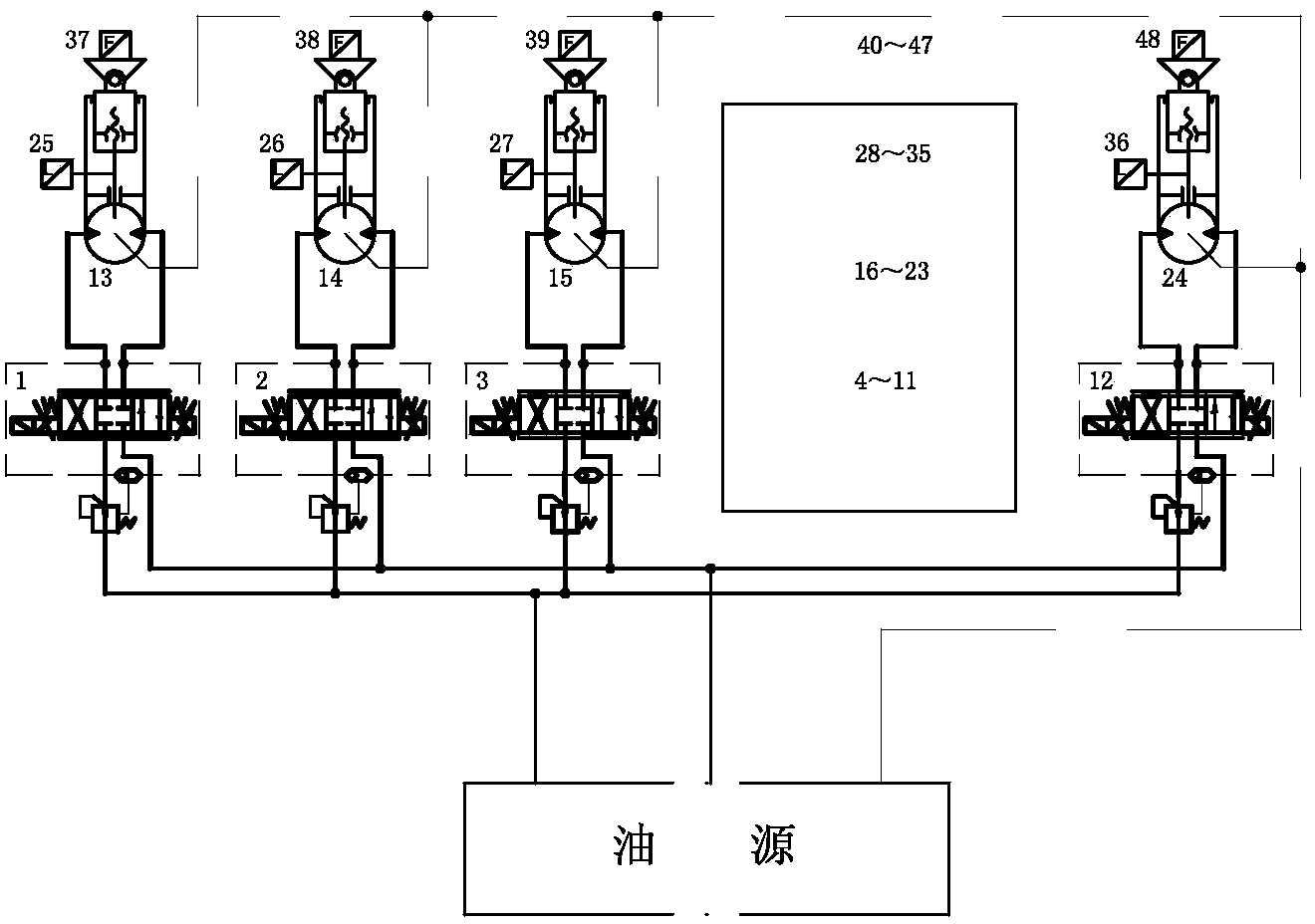

[0028] like figure 1 As shown, the plane flip multi-point leveling device of the present invention includes a first hydraulic support leg 13, a second hydraulic support leg 14, a third hydraulic support leg 15, a fourth hydraulic support leg 16, a fifth hydraulic support leg 17, a sixth hydraulic support leg Hydraulic outrigger 18, seventh hydraulic outrigger 19, eighth hydraulic outrigger 20, ninth hydraulic outrigger 21, tenth hydraulic outrigger 22, eleventh hydraulic outrigger 23, twelfth hydraulic outrigger 24, One displacement sensor 25, the second displacement sensor 26, the third displacement sensor 27, the fourth displacement sensor 28, the fifth displacement sensor 29, the sixth displacement sensor 30, the seventh displacement sensor 31, the eighth displacement sensor 32, the ninth displacement sensor Sensor 33, the tenth displacement sensor 34, the eleventh displacement sensor 35, the twelfth displacement sensor 36, the first outrigger force sensor 37, the second ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com