Water tank liquid level control method based on generalized prediction control optimization

A technology of generalized predictive control and liquid level control, used in liquid level control, non-electric variable control, control/regulation systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

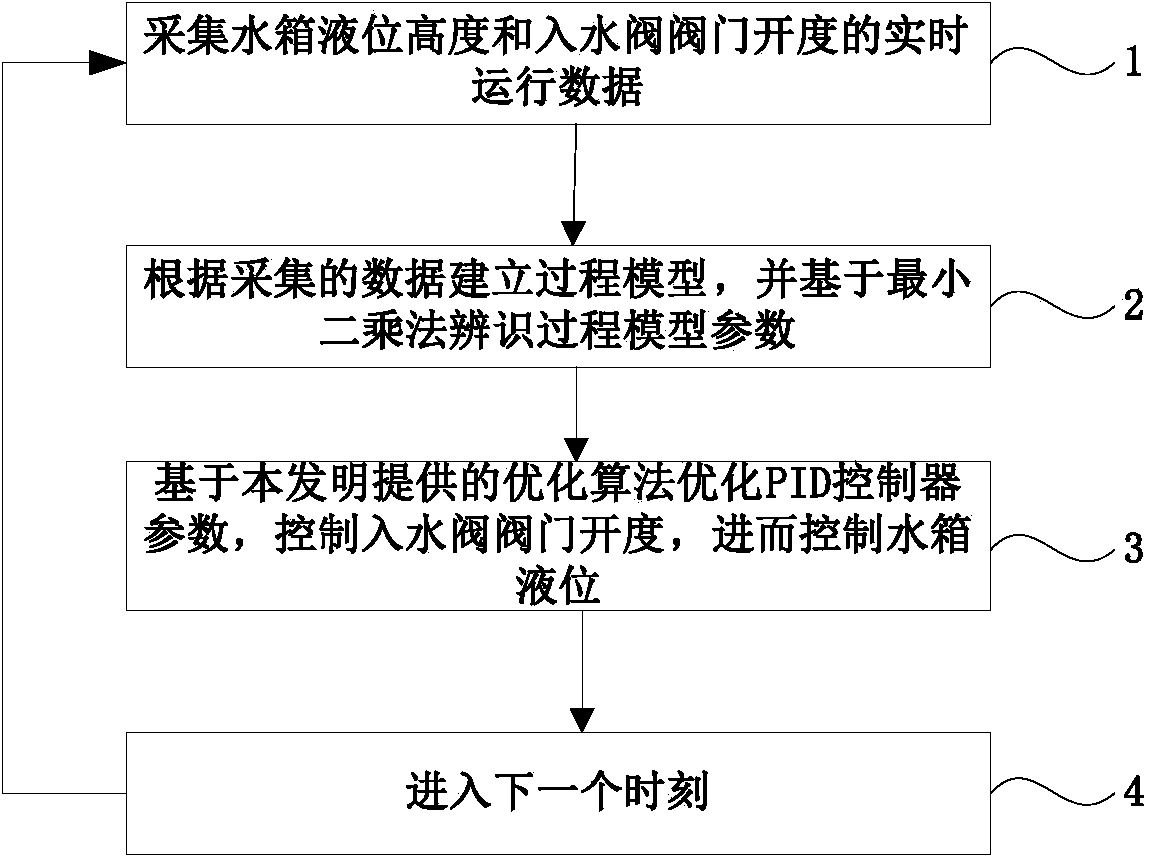

[0041] figure 1 It is a flow chart of the water tank liquid level control method optimized based on generalized predictive control, such as figure 1 As shown, the water tank liquid level control method based on generalized predictive control optimization provided by the present invention includes:

[0042] Step 1: Collect the data of the liquid level of the water tank and the opening of the water inlet valve at each moment.

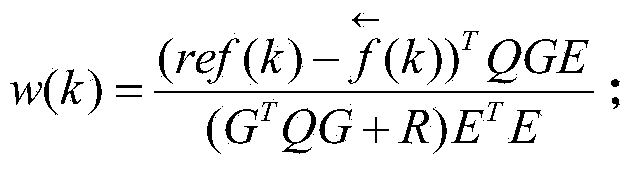

[0043] Step 2: According to the collected data, use the least square method to identify and set the PID controller parameters of the water inlet valve at the current moment, including:

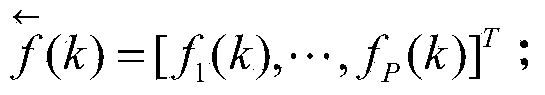

[0044] Sub-step A1: Using the collected liquid level of the water tank as output data and the collected wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com