Visualization experiment device for deep-low-temperature condensation heat exchanging process

A technology of condensation heat exchange and experimental equipment, which is applied in the direction of educational appliances, instruments, teaching models, etc., can solve the problems that cannot be applied to deep and low temperature condensation, and achieve the effect of visualization and convenient observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The following is a detailed description of the visualization experiment device for the deep-low temperature condensation heat exchange process of the present invention in conjunction with the accompanying drawings.

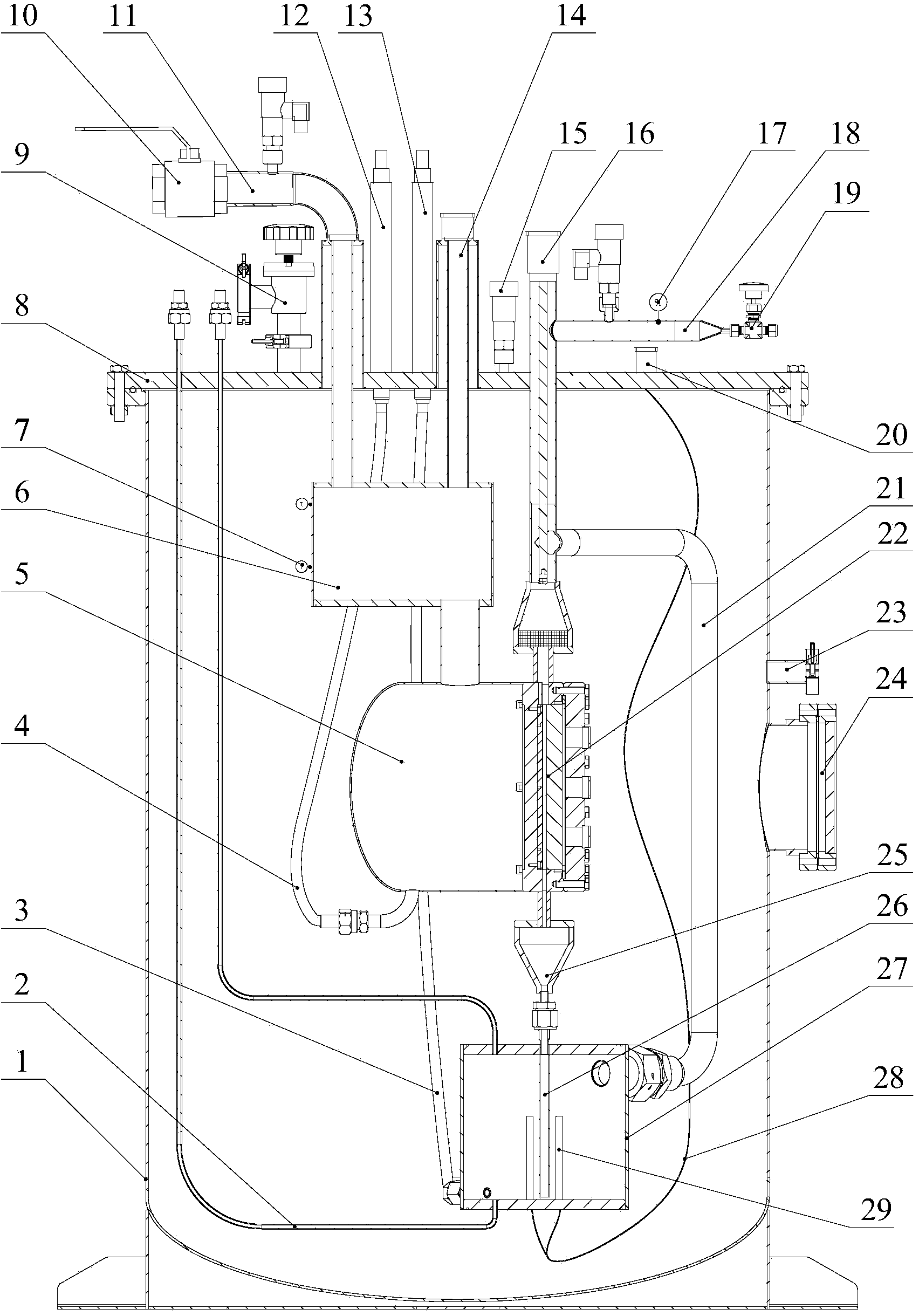

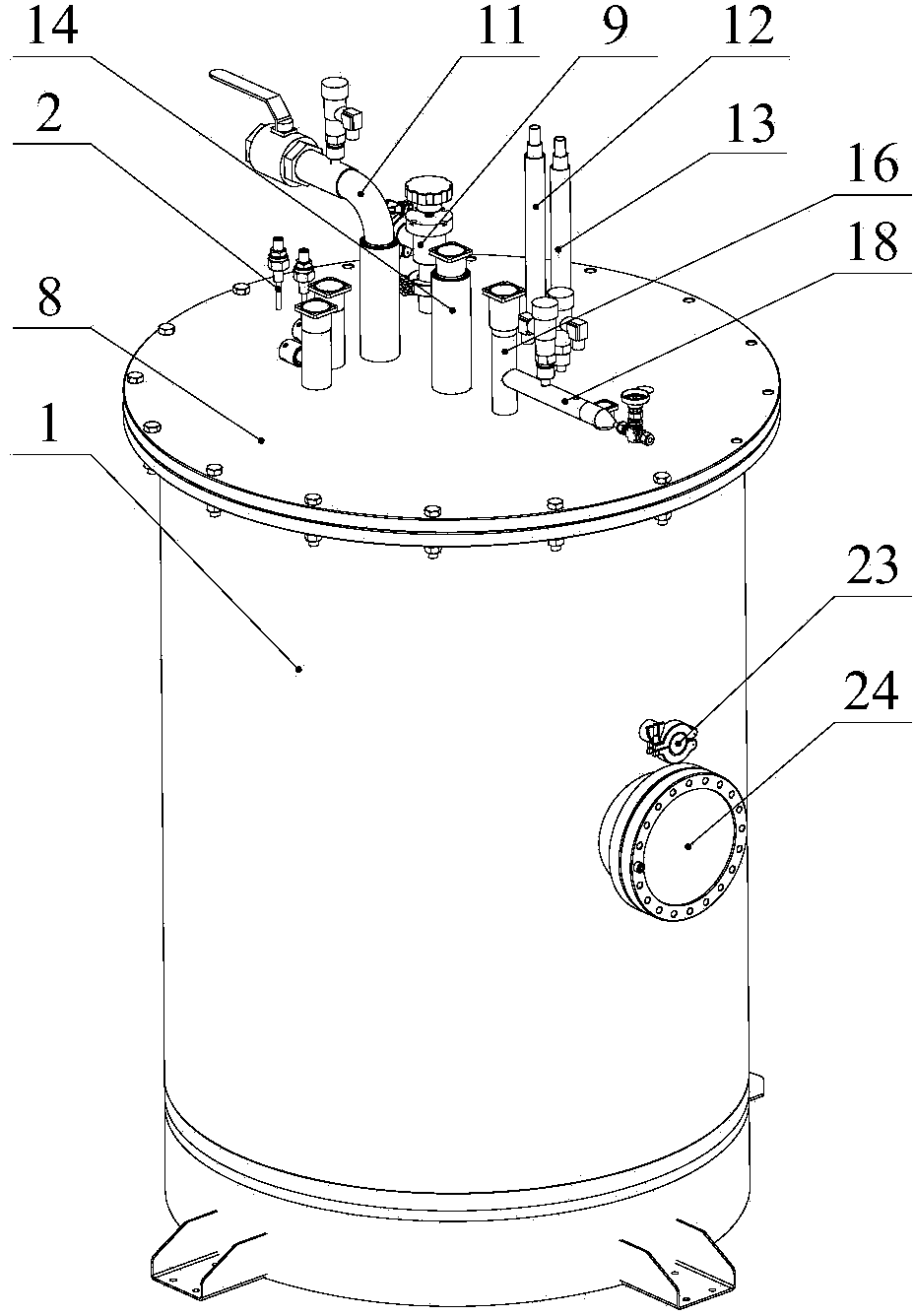

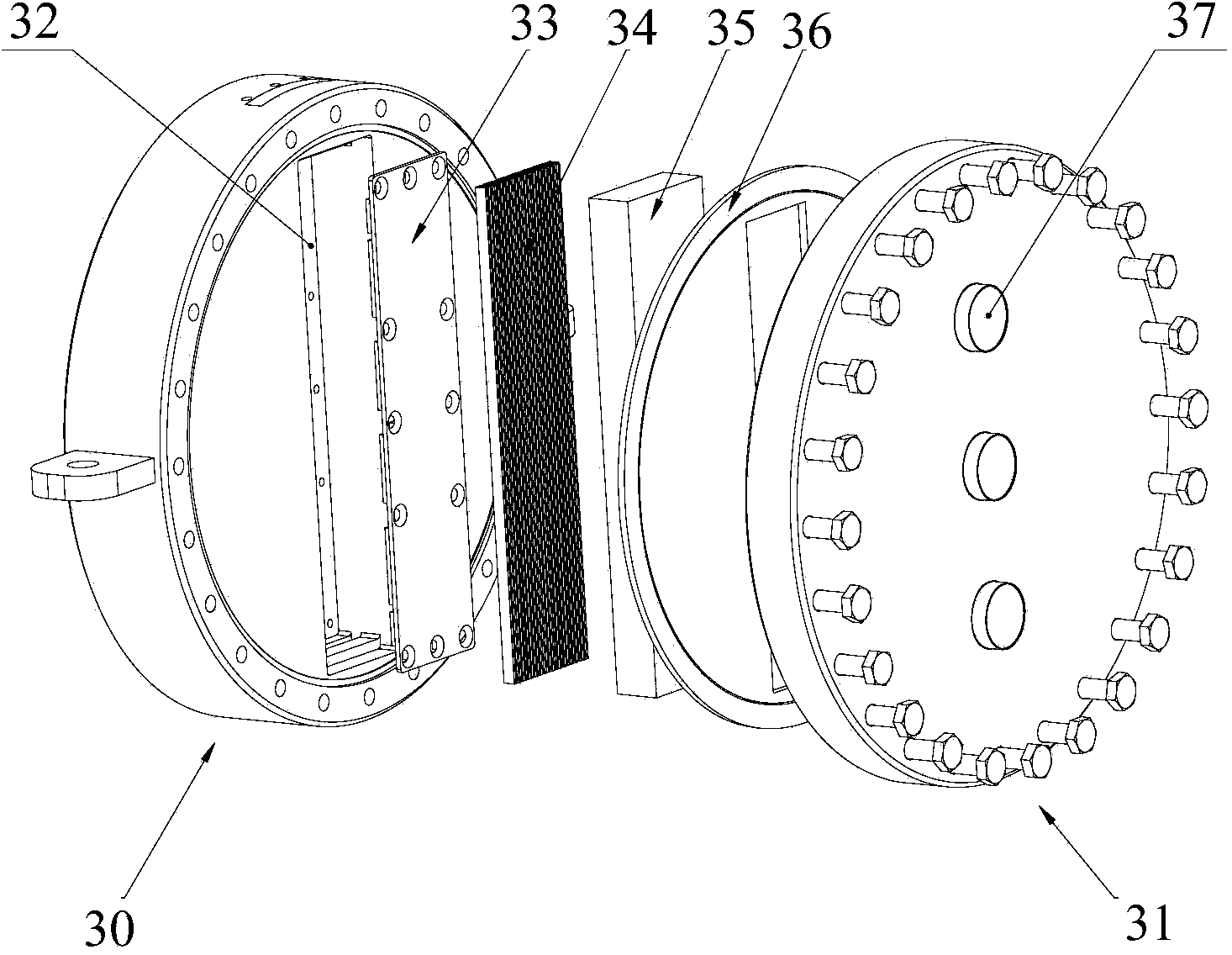

[0075] Such as figure 1 , 2 As shown in the figure, a visual experiment device for the deep-low temperature condensation heat transfer process includes a vacuum box composed of a sealed vacuum cover 1 and a flange 8, and the flange is provided with an evacuation valve 9 and a safety valve 15. The interior of the vacuum box is equipped with:

[0076] The reboiler is used to contain and vaporize the deep-low temperature liquid. The reboiler includes a tank body 27 and a heating element 29 arranged at the bottom of the tank body. The electric wire 28 of the heating element passes through the electrical connector seat 20 to the outside of the vacuum box , the upper and lower ends of the tank body 27 are provided with a capillary 2 extending to the outside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com