Non-contact power supply system using frequency conversion soft switching driving technology and driving method thereof

A power supply system, non-contact technology, applied in the field of frequency conversion soft switching, can solve the problems of low non-contact energy transmission, drive frequency has not been seen, can not guarantee the optimization of the total efficiency of the circuit, etc., to achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

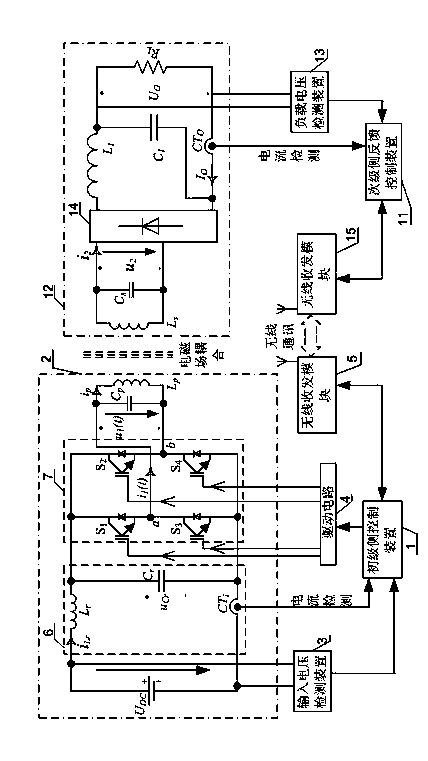

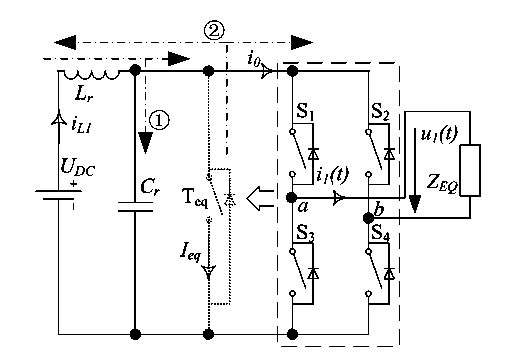

[0016] Such as figure 1 As shown, a non-contact power supply system includes a primary circuit 2 and a secondary circuit 12, the primary circuit 2 transmits energy to the secondary circuit 12, the primary side control device 1 and the input voltage detection device 3, the input current detection device CT i , drive circuit 4, wireless transceiver module 5 are connected, input voltage detection device 3, input current detection device CT i Separate detection of DC power U DC The terminal voltage and current of the primary side control device 1 converts the control signal to drive the switch tube S through the drive circuit 4 1 ~S 4 On and off voltage; secondary side feedback control device 11 and load voltage detection device 13 and load current detection device CT O , the wireless transceiver module 15 is connected, the load voltage detection device 13 and the load current detection device CT O Check the load separately R L terminal voltage and current.

[0017] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com