Waterproof breathable film

A waterproof breathable membrane and waterproof membrane technology, which is applied to electrical components, electric components, casings/covers/supports, etc., can solve the problems that the waterproof membrane is easily covered by liquid and fails, the assembly of waterproof components is complicated, and the production cost of waterproof components is high. , to achieve the effect of simple structure, low production cost and convenient disassembly and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

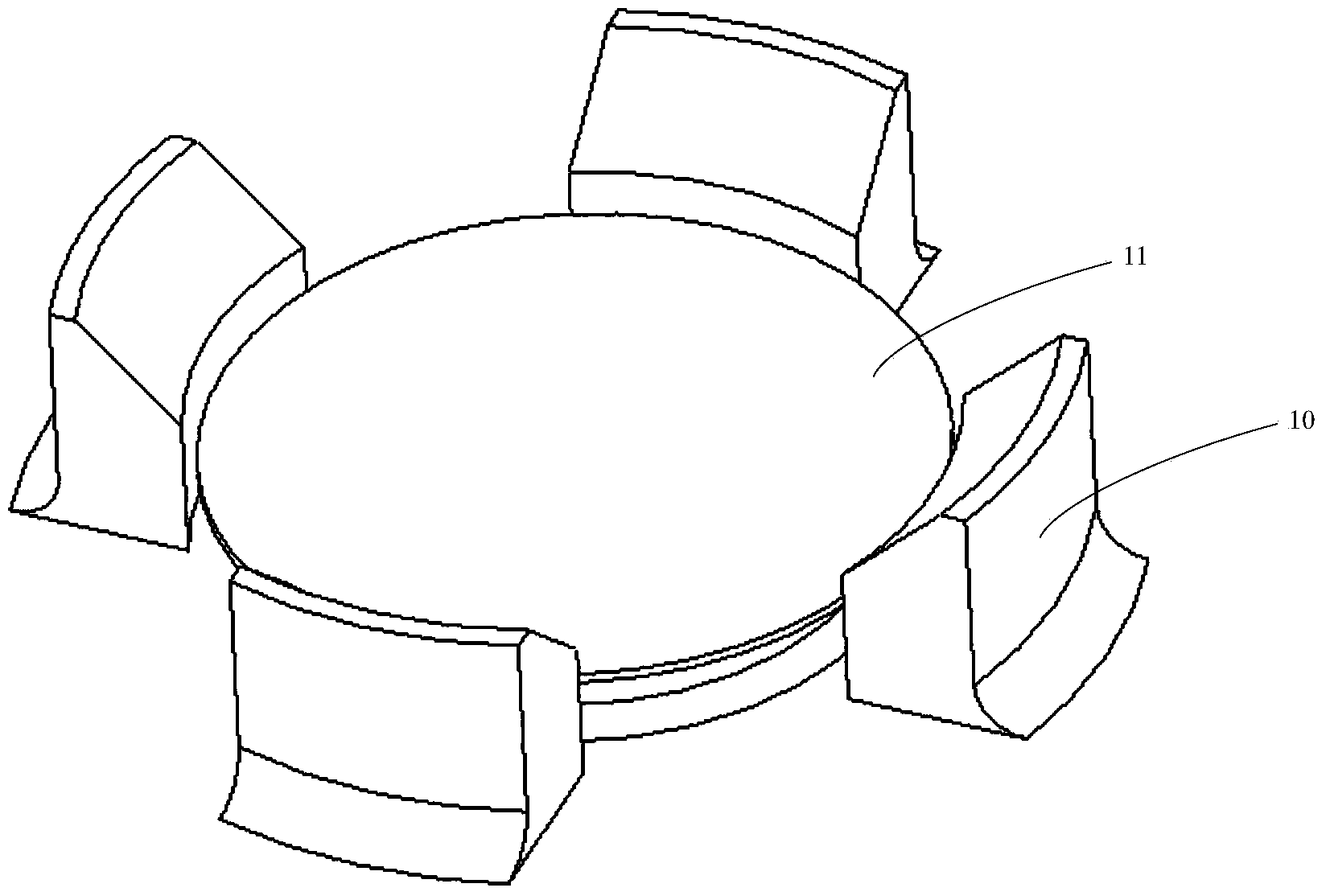

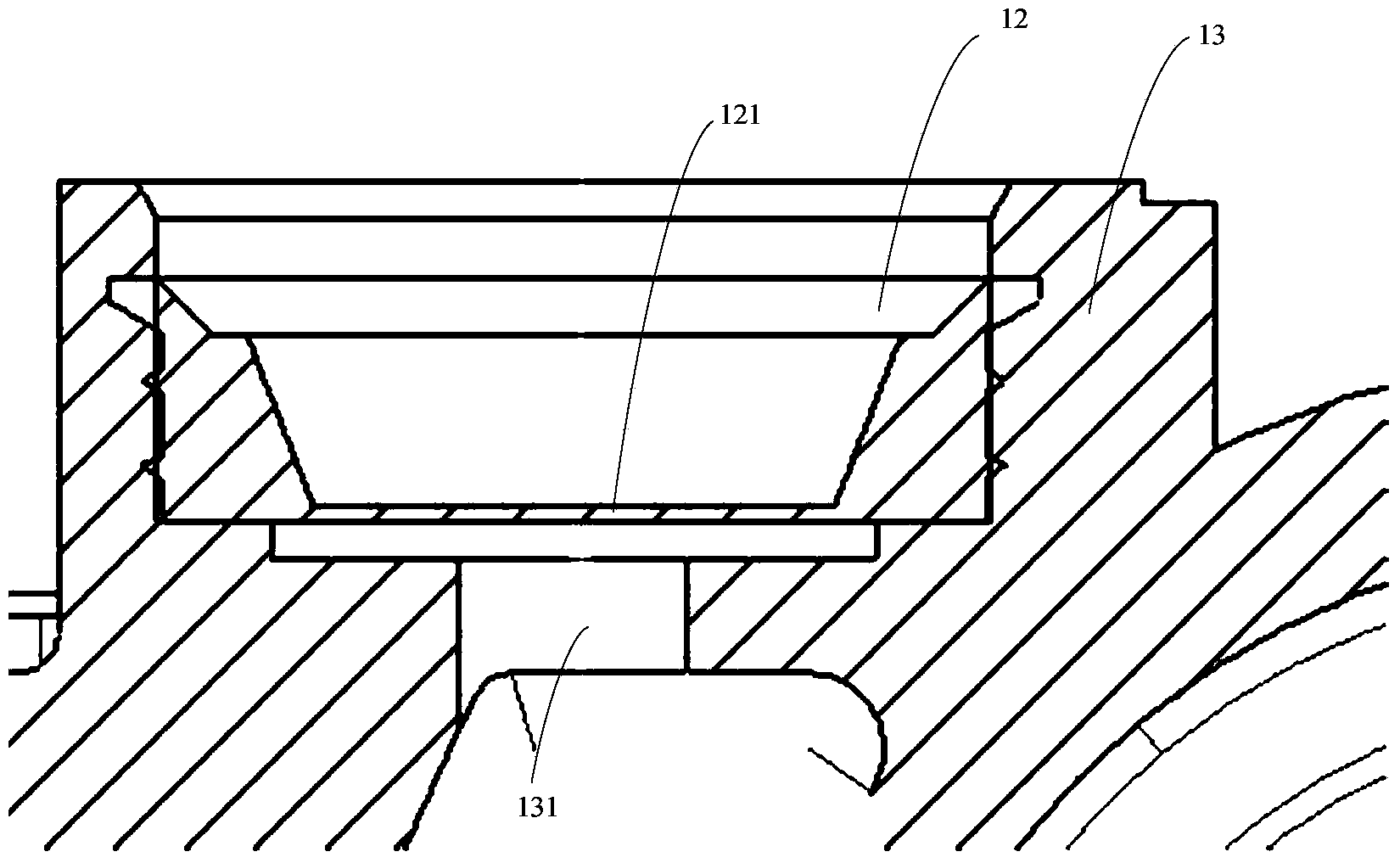

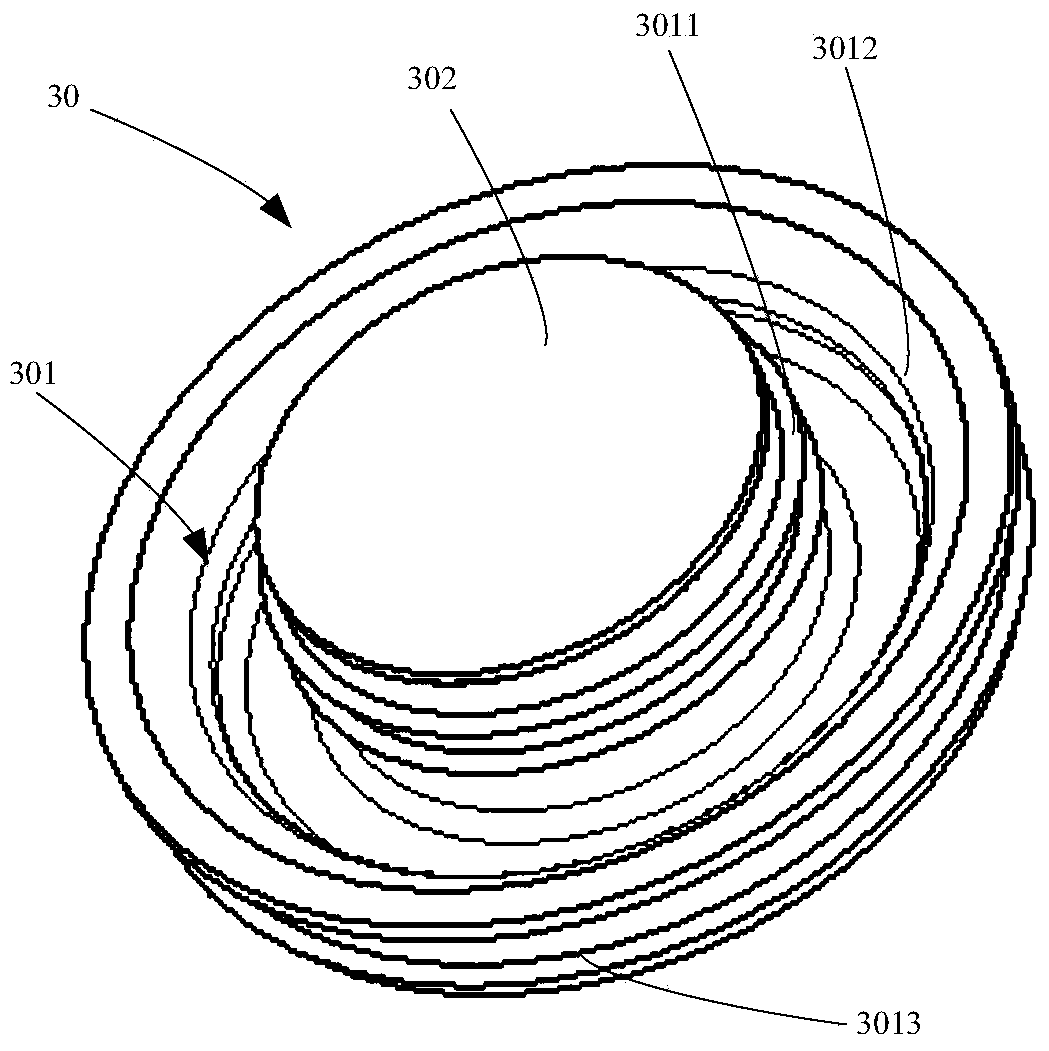

[0027] refer to image 3 , shows a schematic perspective view of a preferred embodiment of the waterproof and breathable membrane of the present invention. The waterproof and breathable film of the present invention is installed at the vent hole provided on the motor, and prevents water vapor and dust particles from entering the vent hole through the waterproof film. , combined with Figure 5 As shown, the height h2 of the waterproof membrane is higher than the height H1 of the drainage groove installed on the motor, which protects the waterproof membrane and ensures that the accumulated water in the cavity is discharged from the drainage groove to prevent the waterproof membrane from becoming invalid due to the immersion of accumulated water. The height h2 of the waterproof membrane is lower than the height H2 of the casing of the motor, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com