Split type brushless motor

A brushless motor, split-type technology, applied in the direction of electrical components, electromechanical devices, magnetic circuit shape/style/structure, etc., can solve the problems of high noise, achieve the effect of low noise, prolong service life and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

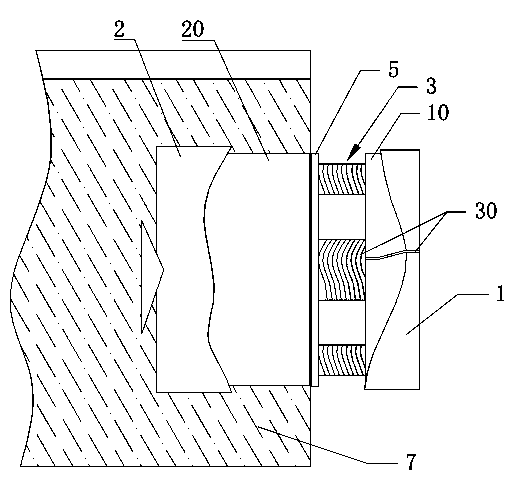

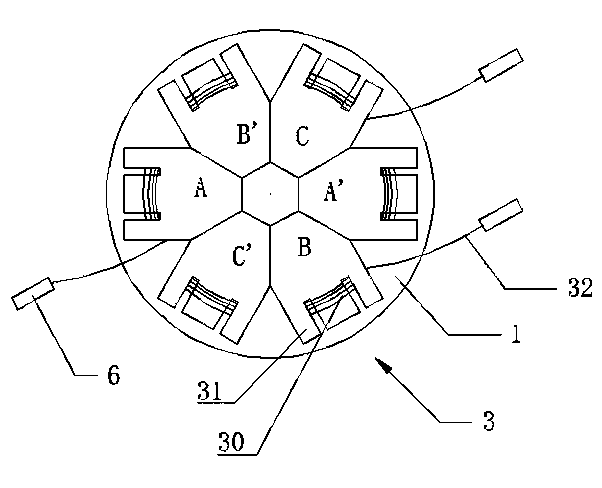

[0023] Such as figure 1 , figure 2 with image 3 As shown, a split-type brushless motor includes a stator assembly and a rotor assembly, and the stator assembly and the rotor assembly are of a split structure, arranged in parallel and arranged coaxially;

[0024] Among them, the stator assembly is arranged in the stator housing 1, wherein the stator assembly includes a stator 10, and the stator 10 is provided with six windings 3, which are divided into three groups; at the same time, the stator housing 1 is provided with an electric adjustment board 5, and the electric adjustment board 5 is located on the side close to the rotor assembly; the electric adjustment board 5 is electrically connected to three position sensors; the position sensor is a Hall sensor 6, and each Hall sensor 6 is used to detect the magnetic pole change on a large-diameter strong magnet The above-mentioned electric adjustment board 5 is electrically connected to the driver; the stator assembly...

Embodiment 2

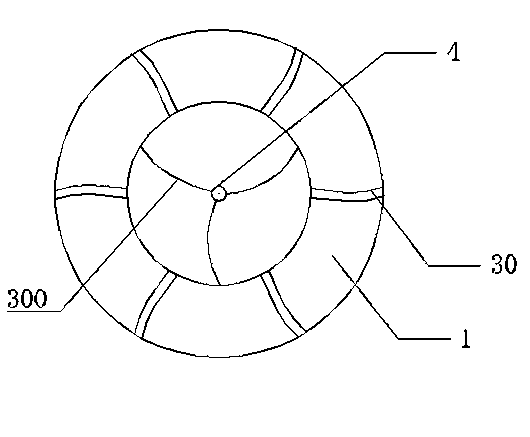

[0032] Such as Figure 4 As shown, this embodiment is basically the same as the first embodiment, except that the rotor 20 has three pairs of magnetic poles, that is, includes three pairs of N magnetic poles and S magnetic poles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com