Method for manufacturing fluorescent lamp and fluorescent lamp manufactured by means of said method

A manufacturing method and technology of fluorescent lamps, which are applied in the manufacture of discharge tubes/lamps, ships or leading wires, cold cathodes, etc., can solve problems such as the inability to realize full spiral lamps, reduce defective rates, and reduce manufacturing cost, and the effect of reducing the use of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

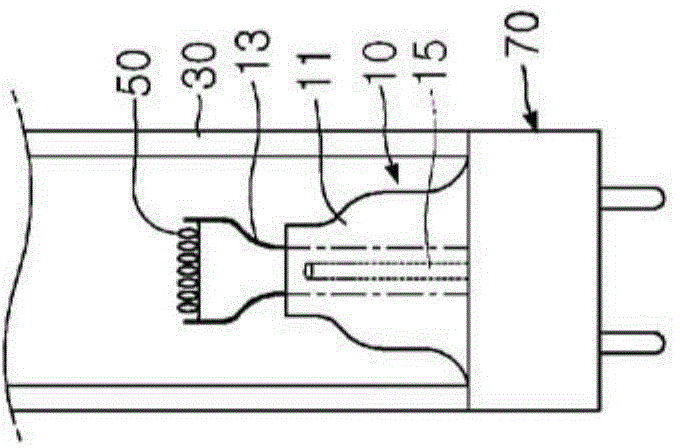

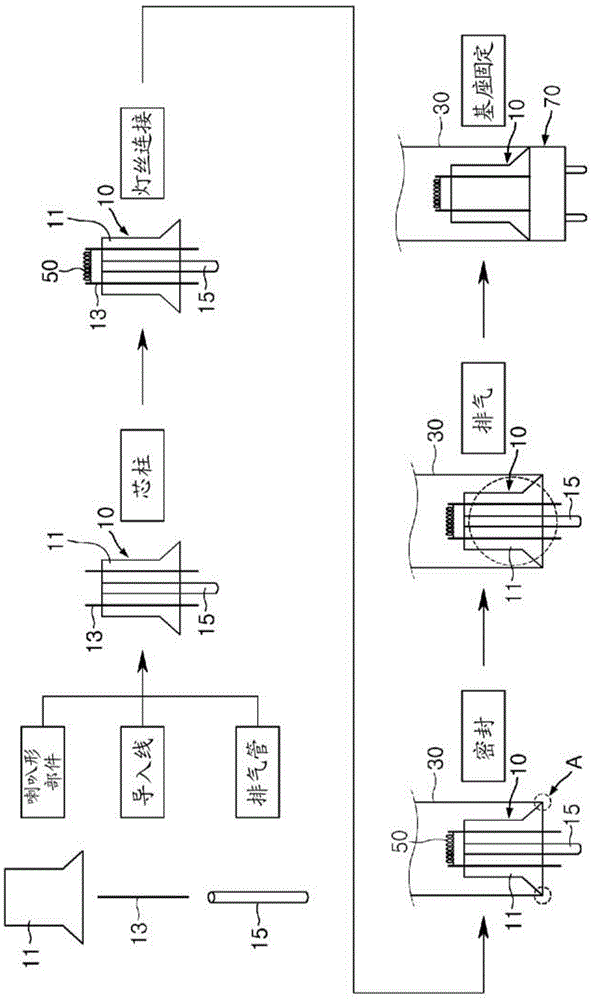

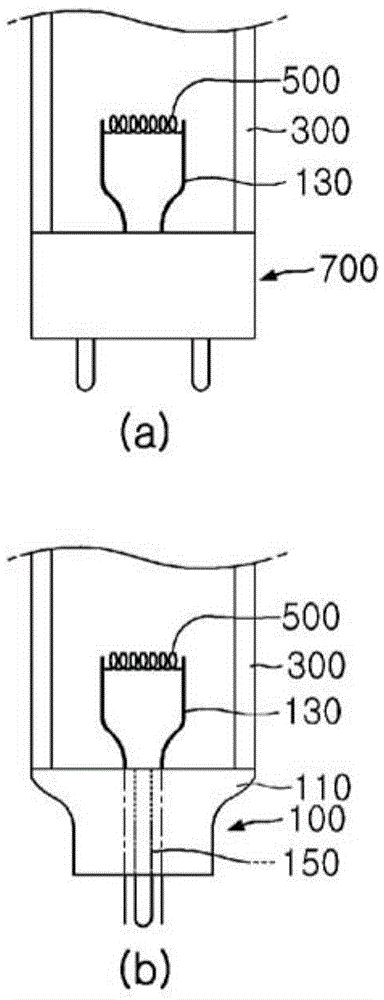

[0045] In order to illustrate the present invention, the operational advantages of the present invention, and the objectives achieved by implementing the present invention, preferred embodiments of the present invention are listed below and described with reference to the preferred embodiments.

[0046] First of all, the terms used in this application are only used to describe specific embodiments, and are not intended to limit the present invention. Since it is difficult to clearly express the singular in language expression, the expression of the singular also includes the expression of the plural. In addition, in this application, terms such as "comprising" or "having" are intended to specify the existence of features, numbers, steps, actions, structural components, parts or their combinations described in the specification, and should not be interpreted as pre-excluding one or Other features above it, or the presence of numbers, steps, actions, structural components, parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com