Robot and assembly method thereof

A technology for robots and output flanges, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

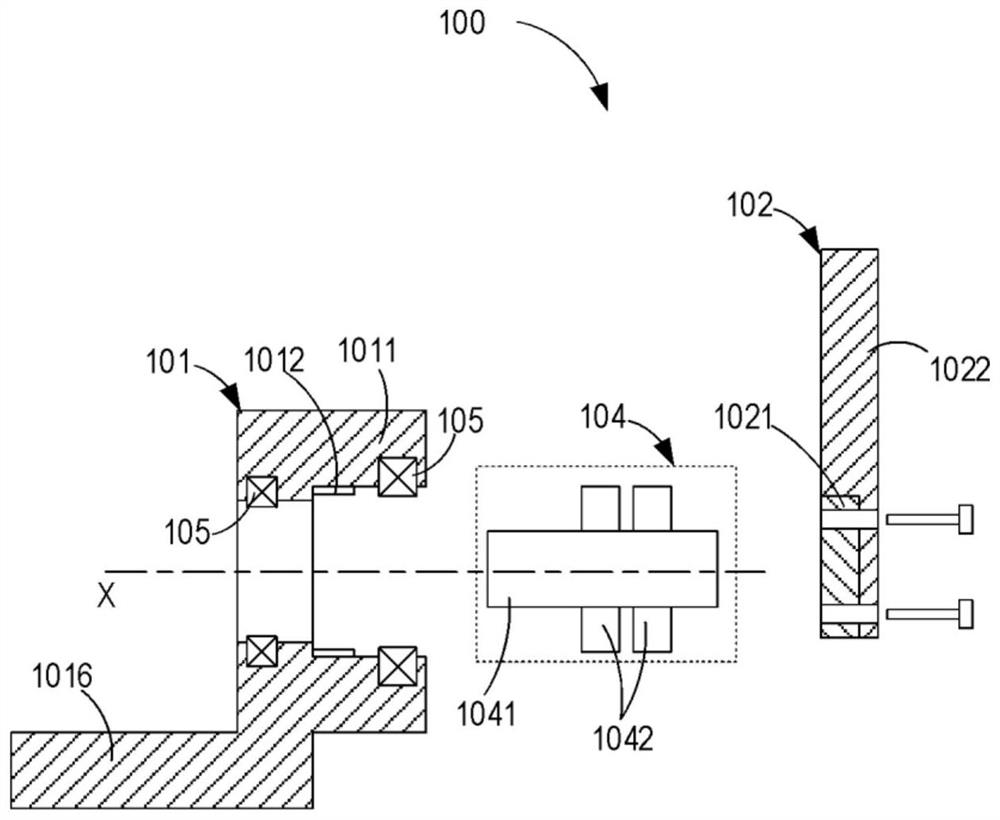

[0031] The present disclosure will now be discussed in connection with several example embodiments. It should be understood that the purpose of discussing these embodiments is only to enable those skilled in the art to better understand and realize the present disclosure, rather than implying any limitation on the scope of the subject matter.

[0032] As used herein, the term "comprising" and its variants should be understood as open terms meaning "including but not limited to". The term "based on" should be understood as "based at least in part on". The terms "one embodiment" and "an embodiment" are to be read as "at least one embodiment." The term "another embodiment" is to be understood as "at least one other embodiment". The terms "first", "second", etc. may refer to different or the same object. Other explicit and implicit definitions may be included below. Unless the context clearly indicates otherwise, the definitions of terms are consistent throughout the specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com