Reaction vessel-type decoloration device of industrial oil

A technology for industrial oil and reaction kettle, applied in chemical/physical/physical-chemical stationary reactors, etc., can solve the problems of insignificant effect, increased equipment use cost, low efficiency of oil decolorization treatment, etc., to reduce production costs , The effect of improving production efficiency and shortening mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below through specific examples, but not in order to limit the present invention, all within the spirit and principle of the present invention, any modification, equivalent replacement, improvement etc. all should be included within the scope of protection of the present invention .

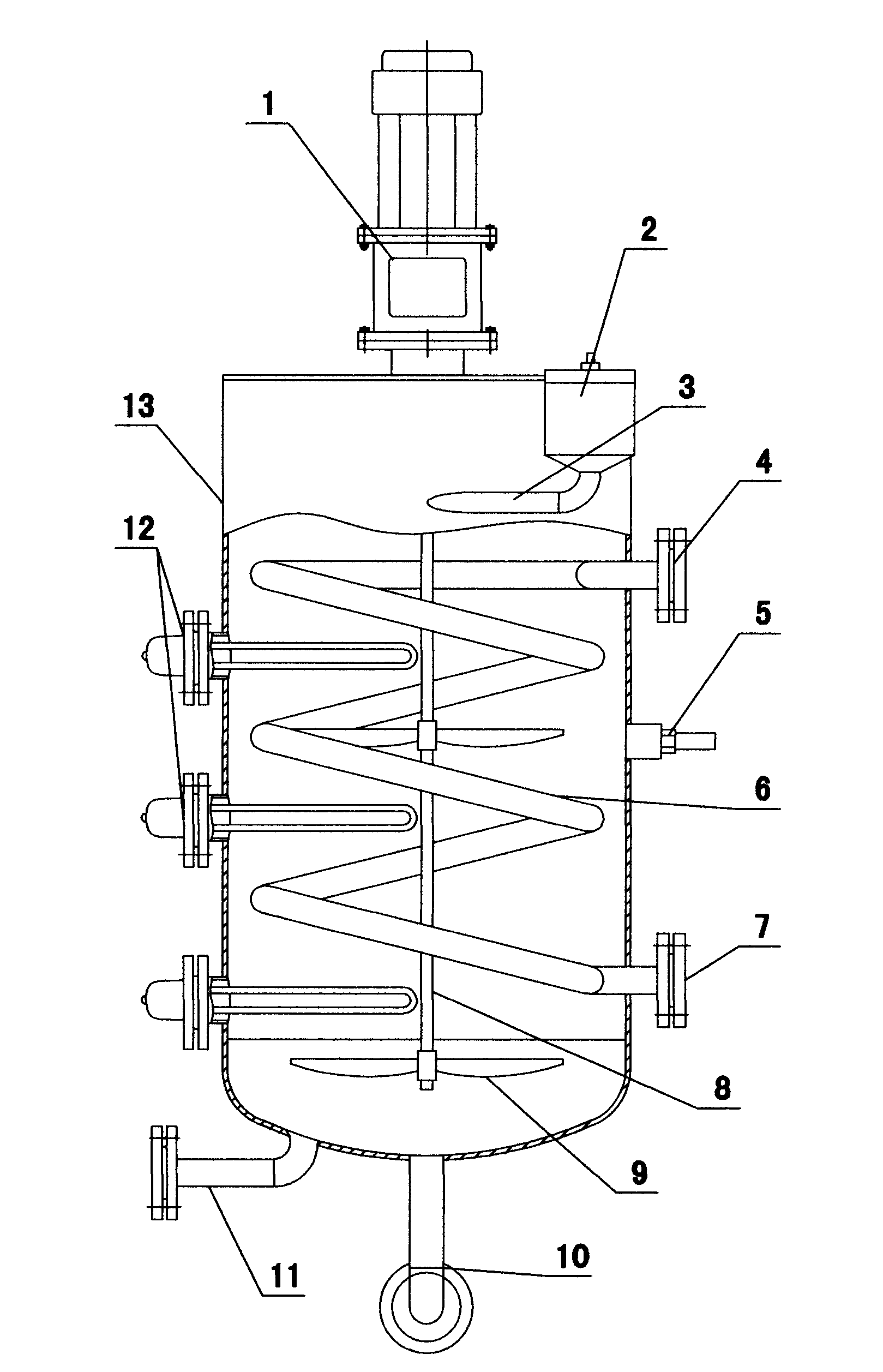

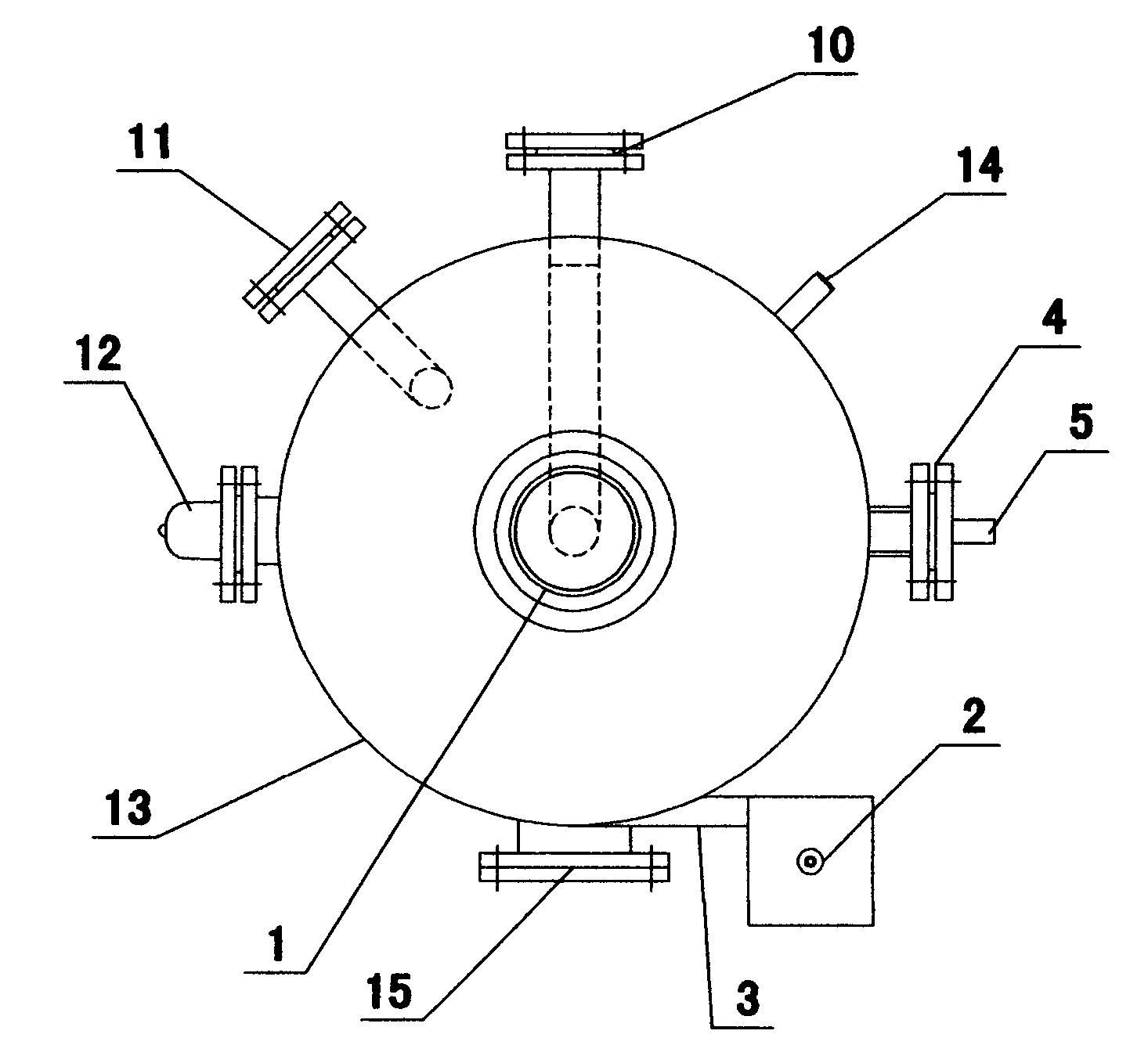

[0023] Such as figure 1 , figure 2 As shown, the industrial oil reactor type decolorization device includes a tank body 13, a material inlet 11 and a material outlet 10 are arranged at the bottom of the tank body 13, an agitator 1 is installed on the top of the tank body 13, and on the left side wall of the tank body 13 A heater 12 is installed, the heating end of the heater 12 is arranged in the tank body 13, a temperature detector 5 for temperature detection in the tank body 13 is installed on the right side wall of the tank body 13, and a cooling pipeline is arranged in the tank body 13 6. A decolorizing agent storage tank 2 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com