Elastic wall surface micro-fluidic chip based on T-shaped micro-channel

A microfluidic chip and microchannel technology, which can be used in laboratory containers, laboratory utensils, chemical instruments and methods, etc., and can solve problems such as droplet inhomogeneity and inhomogeneity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

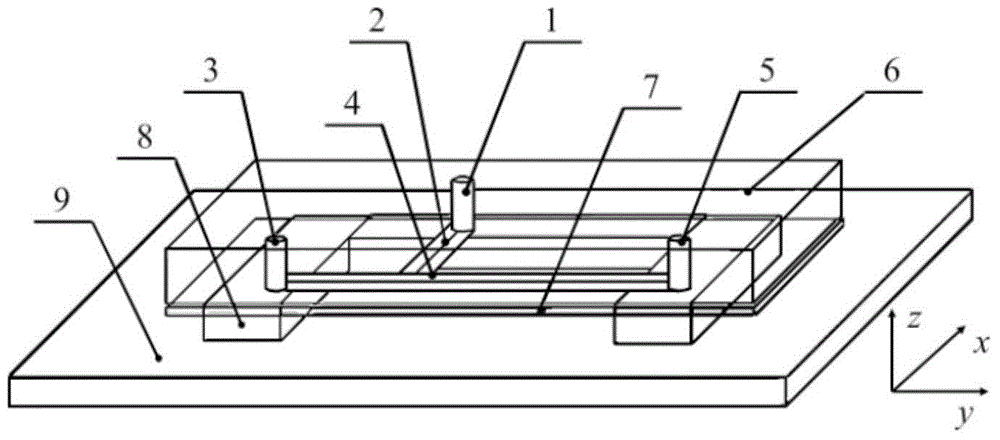

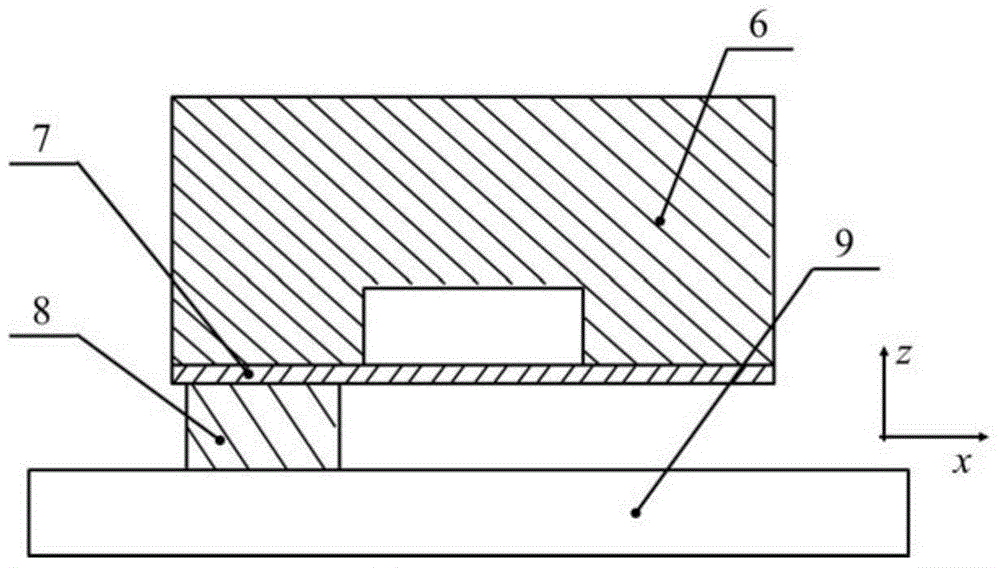

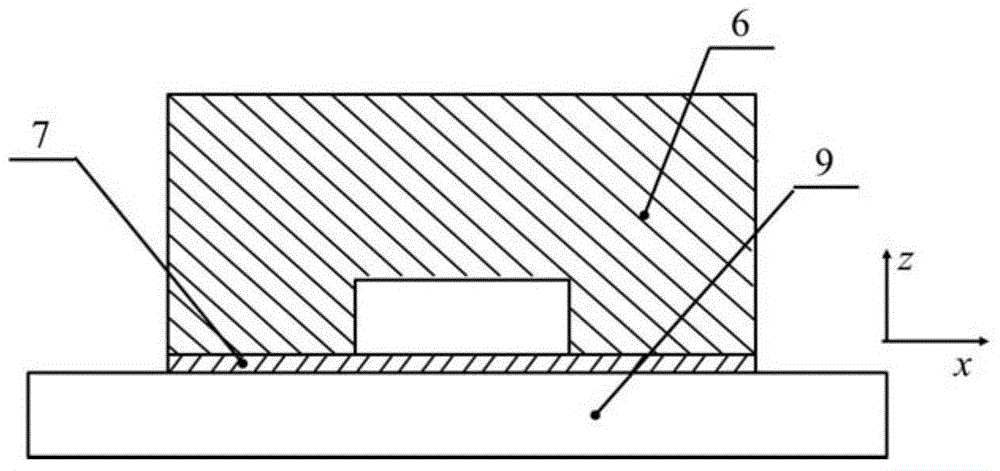

[0020] The working process and effect of the elastic wall microfluidic chip based on the T-shaped microchannel will be further explained and verified in the following in conjunction with the structural drawings. Due to the small size of the microchannel, the actual size of the microfluidic chip cannot effectively represent the microfluidic chip. The structure of the flow channel part of the fluidic chip, so the attached diagram uses a relatively enlarged chip schematic diagram of the micro flow channel structure.

[0021] figure 1 It is a schematic diagram of the three-dimensional general outline of the elastic wall microfluidic chip based on the T-shaped microchannel. The elastic bottom T-shaped microchannel chip mainly includes a discrete phase inlet 1, a side channel 2, a continuous phase inlet 3, a main channel 4, an outlet 5, a main solid structure 6, a film bottom structure 7, a base 8, and a glass slide 9. composed of parts. Figure 4 It is a schematic diagram of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com