Automatic waste sorting and compression recycling bin

A technology of automatic sorting and recycling bins, applied in presses, garbage collection, household appliances, etc., can solve the problems of high production and maintenance costs, and the inability to automatically sort and store beverage bottles and cans of different materials, so as to achieve low product cost and low maintenance. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure of the present invention will be further described below in conjunction with the accompanying drawings and preferred specific embodiments of the present invention.

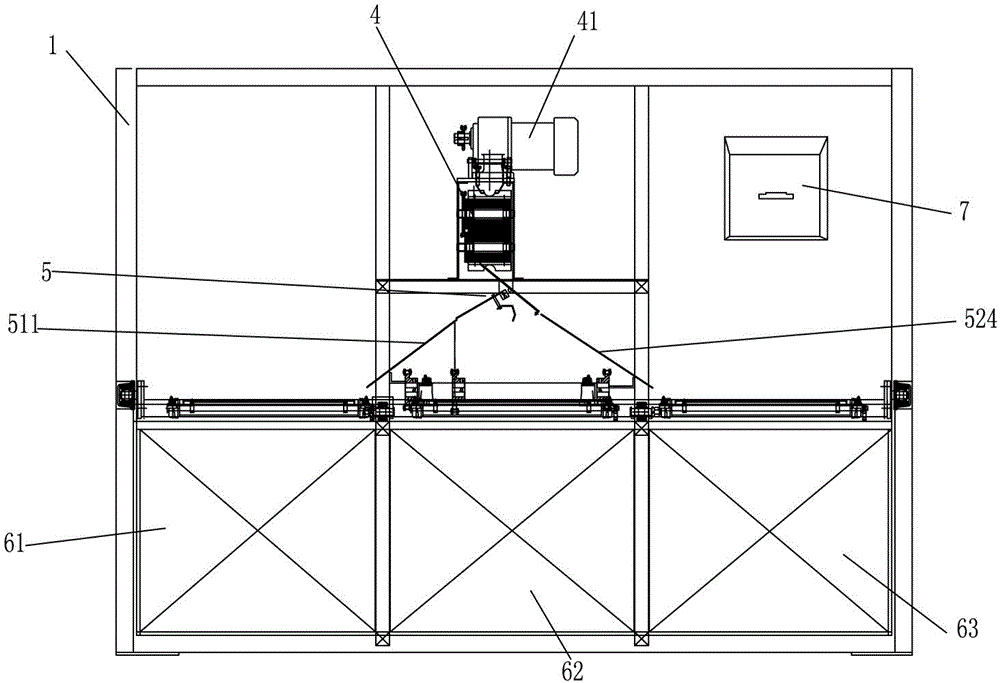

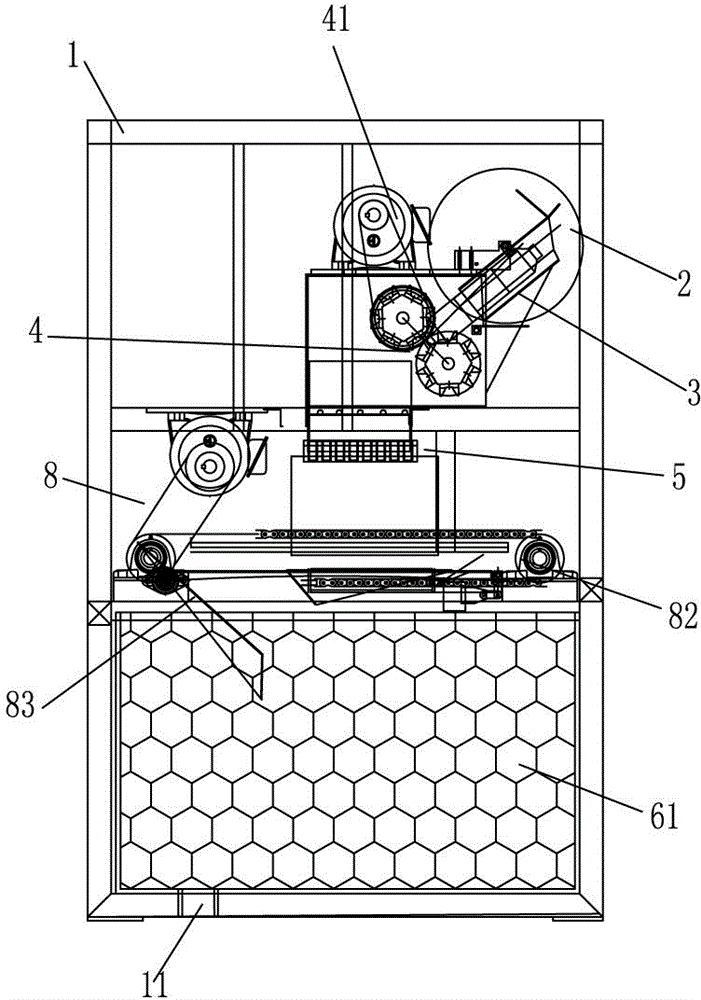

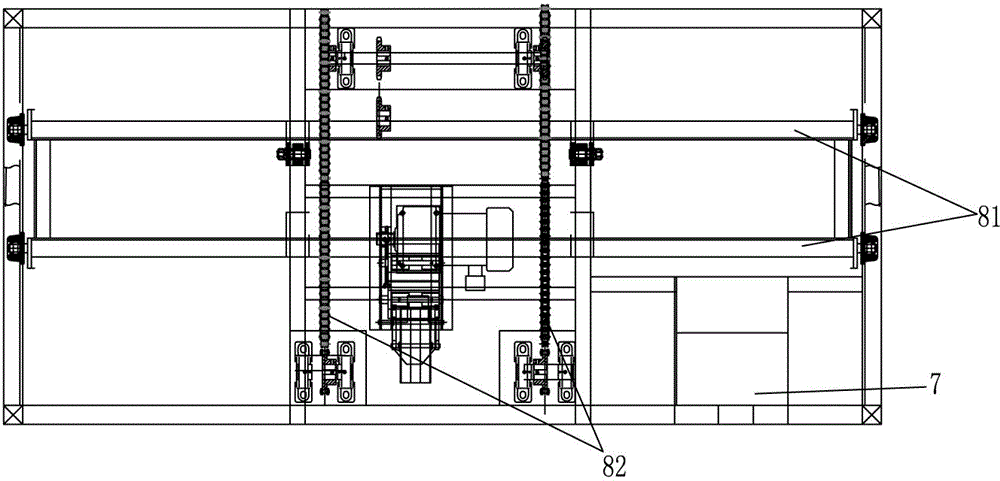

[0022] refer to Figure 1 to Figure 3 Shown in, the present invention comprises a box body 1, is provided with feeding opening 2 on the front of box body 1, and recyclable beverage bottle can can be dropped into from this feeding opening 2; Corresponding slideway 3, the bottom end of slideway 3 is provided with corresponding rolling mechanism 4; The bottom of rolling mechanism 4 is provided with classification delivery mechanism 5, and the bottom of classification delivery mechanism 5 is provided with at least three collecting frames 61,62, 63; In order to prevent non-recyclable glass bottles from being rolled into the collection frame 61 for collecting plastic beverage bottles and cans by mistake, the bottom of the slideway 3 is provided with a weight-limiting elastic supporting plate, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com