Combined type thread self-locking hydraulic redundant steel supporting shaft force compensation system

A thread and self-locking technology, which is applied to the safety of fluid pressure actuation systems, fluid pressure actuation devices, mechanical equipment, etc., can solve the problems that affect the safe operation of the system, the system occupies a large space, and the number of hydraulic cylinders is large, so as to improve System security, the effect of small system footprint and high system security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

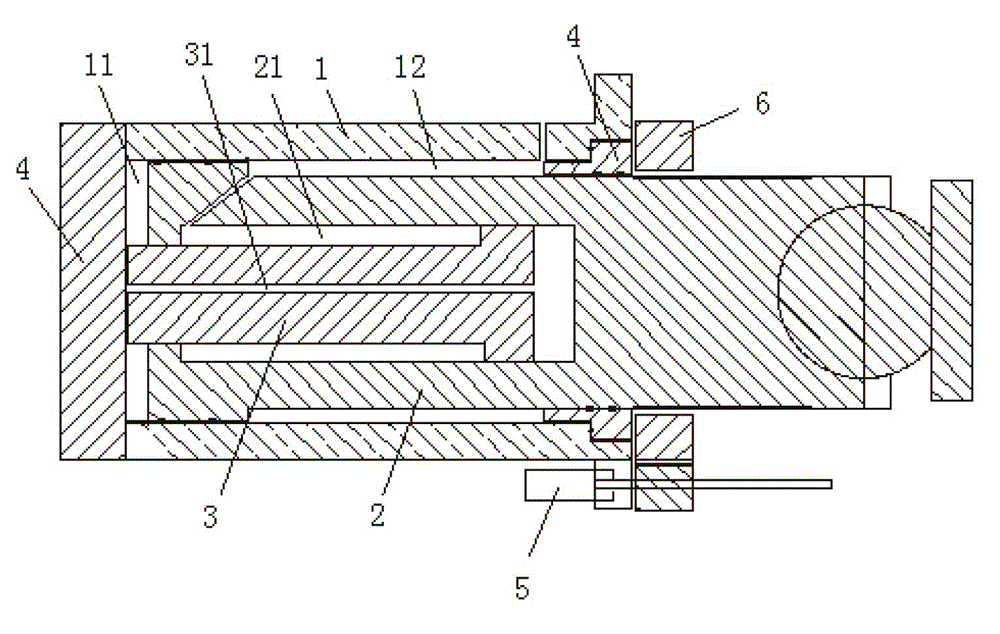

[0016] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

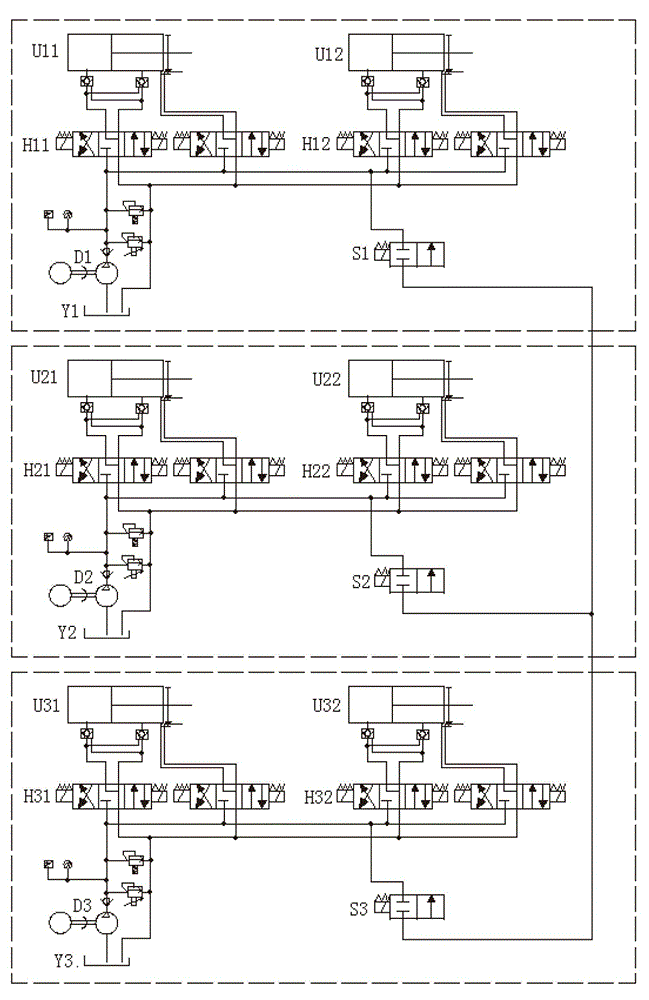

[0017] Such as figure 1 As shown, a composite thread self-locking hydraulic redundant steel support axial force compensation system provided by the embodiment of the present invention includes three power output units, the three power output units are respectively the first power output unit, the second power output unit, and the second power output unit. The second power output unit, the third power output unit;

[0018] The first power output unit includes fuel tank Y1, hydraulic pump D1, redundant valve S1, and two threaded self-locking cylinders U11, U12, and two cylinders drive valves H11, H12. The number of cylinders dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com