Outlet air velocity remote control measurement system outside the furnace for boiler once-through burner

A measurement system and burner technology, which are applied in fluid velocity measurement, velocity/acceleration/impact measurement, and measurement devices, etc., can solve problems such as the wind velocity that cannot represent the nozzle section, occupational health hazards for measurement personnel, and high noise, and achieve the measurement method. Simple and accurate, improve the level of occupational health, reduce the effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

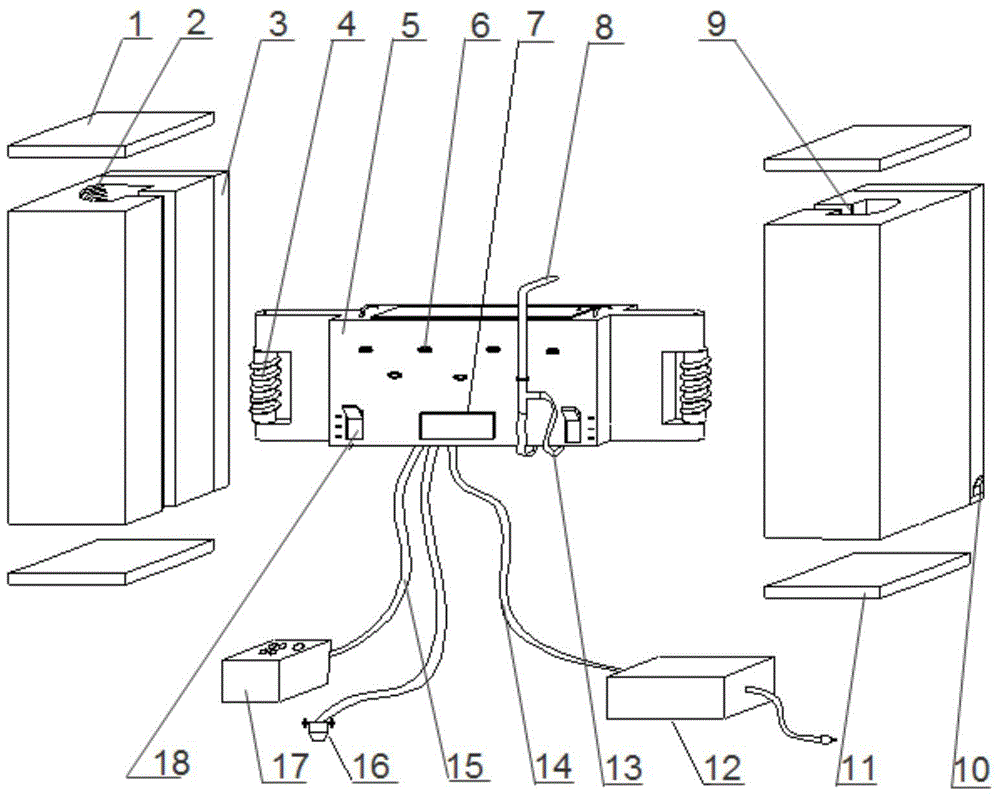

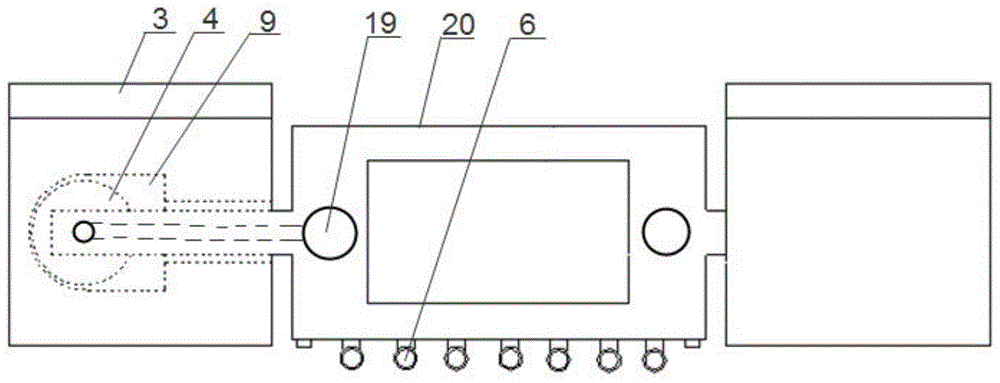

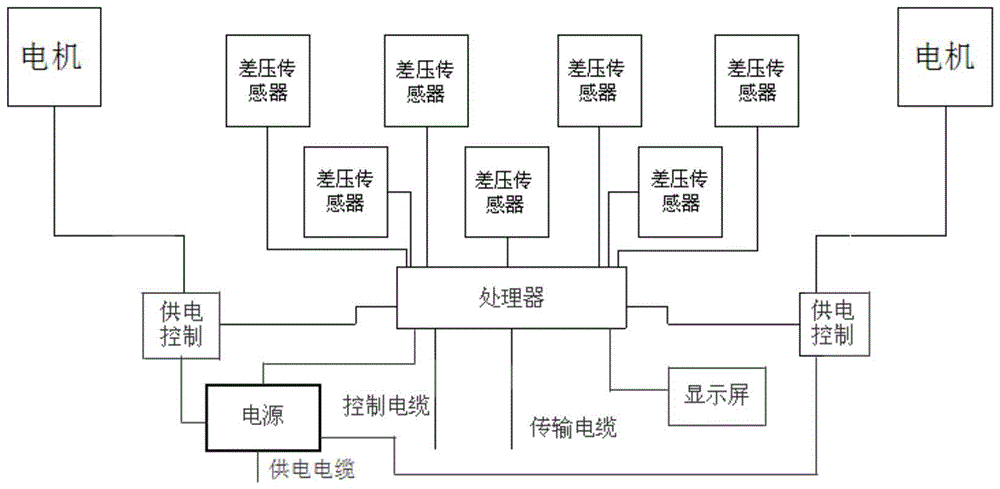

[0021] A remote control measurement system outside the furnace for the outlet wind speed of the boiler once-through burner, such as figure 1 Or as shown in 2, including two guide rail brackets with completely symmetrical structures on the left and right, the anemometer is installed on the guide rail between the left and right guide rail brackets,

[0022] Wherein, the guide rail support includes a bracket base 11 for positioning and leveling. The guide rail body is fixed on the base. In the middle of the guide rail body, a cylindrical track cavity 9 that is vertically upward and opened on one side is formed. On the inner wall of the track cavity, a spiral track 2 is formed from bottom to top, a dust cover plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com