Cooling shaft structure for explosion-proof motor

An explosion-proof motor and cooling shaft technology, used in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of equipment shutdown, low accuracy, affecting production, etc., and achieve accurate and stable fixing, good cooling effect, and assembly. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail in conjunction with accompanying drawing:

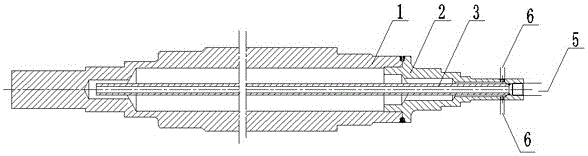

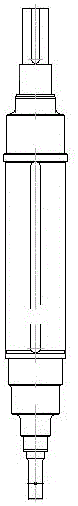

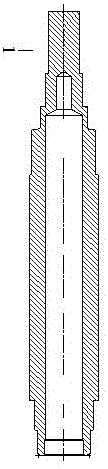

[0027] The cooling shaft structure for explosion-proof motors includes the outer shaft, the inner shaft 3, the shaft rib 4, the medium port A5 and the medium port B6; It is composed of two parts and B. The outer shaft contains the inner shaft 3 and the shaft rib 4 connected together. After the outer shaft A1 and the outer shaft B2 are joined and fixed and sealed, one end of the inner shaft 3 is the medium port A5, and the other end is connected to the outer shaft. Internally connected, there is a medium port B6 on the side of the outer shaft B2, and the medium port A5 and medium port B6 are located on the same side of the cooling shaft structure.

[0028] The inner spaces of the outer shafts A1 and B are both coaxial and different diameters. The space at the closed end of the outer shaft A1 accommodates the inner shaft 3, the inner middle part of the outer shaft A1 accommodates the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com