Improved circular die

A technology of ring die and die wall, applied in the direction of die extrusion granulation, etc., can solve the problems of ring die damage, influence on granulation effect, insufficient strength, etc., and achieve the effect of improving service life, simple structure, and enhancing overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

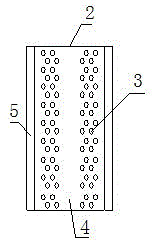

[0018] Such as figure 1 and figure 2 As shown, a kind of improved ring die of the present invention, it comprises ring die body 1, and described ring die body 1 is inner hollow cylindrical shape, is provided with two rows on the mold wall 2 of ring die body 1 Pelletizing holes 3, between the two rows of granulating holes 3 is a non-porous mold wall 4, two granulating holes 3 are arranged on the same horizontal line on each row of granulating holes 3, four adjacent up and down The granulation holes 3 are arranged in a staggered manner; the cross section of the ring die body 1 is circular; the front and rear ends of the ring die body 1 are provided with connecting edges 5, which are integrally formed; the ring die body 1 is an alloy Steel or stainless steel ring die body; the granulation hole 3 is a small hole through the mold wall 2 of the ring die bo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap