Calcinator used for turbine investment casting

A technology of investment casting and roasting furnace, which is applied in the direction of casting molding equipment, molds, mold components, etc., can solve the problems of inaccurate temperature control, product quality decline, inaccurate mold shell temperature, etc., and achieve high temperature control accuracy , Improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

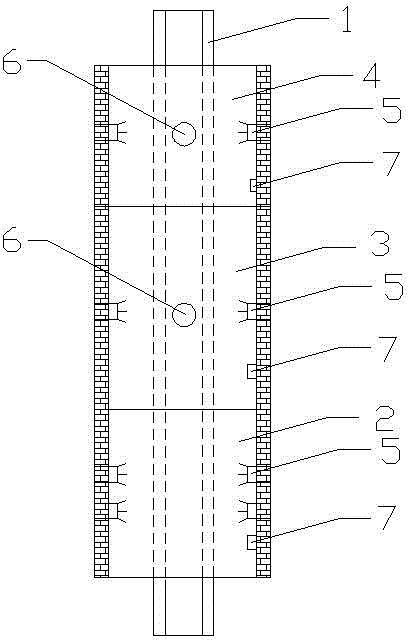

[0017] see figure 1 The present invention relates to a roasting furnace for turbo investment casting, which includes a roasting furnace body and a conveying track 1 passing through the roasting furnace body. Heating zone 4, first spray gun 5 is all arranged on the both sides of described burning zone 2, heat preservation zone 3 and heating zone 4, and the top of described heat preservation zone 3 and heating zone 4 is provided with second spray gun 6, and described spray gun A temperature sensor 7 is provided inside the burning zone 2 , the heat preservation zone 3 and the heating zone 4 . There are two first spray guns 5 on the left wall and the right wall of the burning zone 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com