Clamping device with pull-down function

A technology of clamping device and function, applied in the field of clamping device with pull-down function, can solve the problems of high cost, complex manufacturing structure, affecting positioning accuracy, etc., and achieve the effect of convenient operation and use, simple structure, stable and reliable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

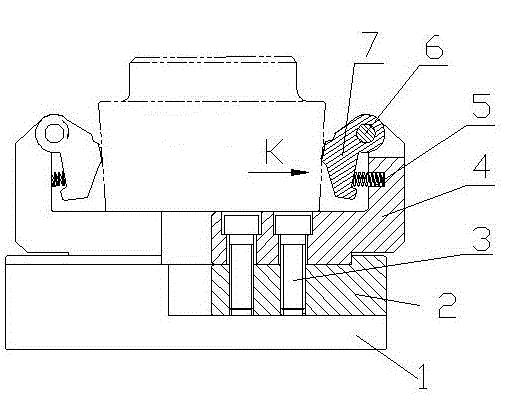

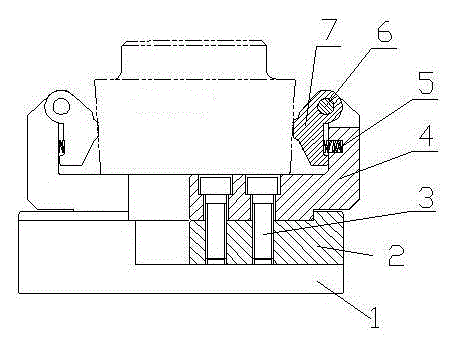

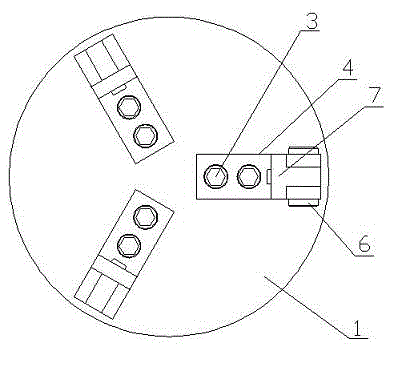

[0015] From figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen from the figure that a clamping device with a pull-down function is provided with a chuck body 1, a slider 2, a jaw body 4, and the like. The chuck body 1 and slider 2 are part of a standard chuck. Three sliders 2 are installed on the chuck body 1 at intervals of 120°, and can move radially along the chuck body 1 .

[0016] The claw body 4 is in an L-shaped structure, the bottom edge of which is fixed on the corresponding slider 2 by fastening screws 3, and the top of the upright edge is connected with a clamping pull-down claw 7 through a pin 6; the clamping pull-down The claw 7 is rotatably engaged on the inner side of the vertical side of the claw body 4, and a spring 5 is arranged between the clamping pull-down claw and the vertical edge of the claw body; The tines 71.

[0017] Further, the inner side of the vertical side of the claw body 4 is provided with a blind hole for installing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com