A continuous fiber spreading equipment for prepreg production and its application method

A continuous fiber and prepreg technology, applied in the production equipment and application fields of prepreg, can solve the problems of re-threading and yarn spreading equipment without specific instructions, achieve uniform yarn arrangement, reduce yarn breakage, eliminate The effect of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

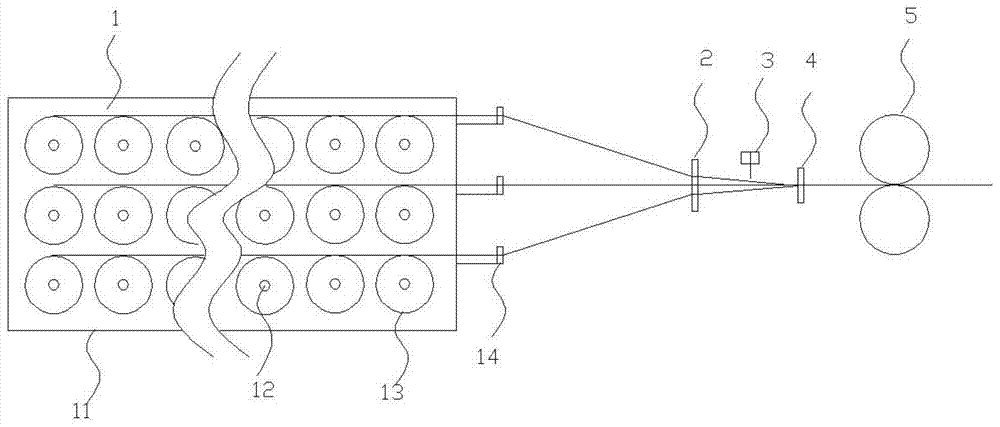

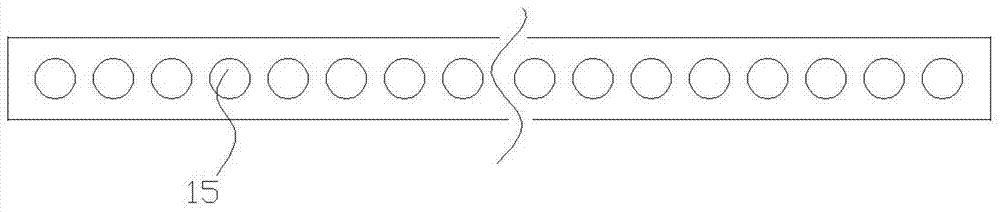

[0028] figure 1 Shown is the yarn spreading equipment of the present invention, taking a schematic diagram of a three-layer creel as an example, the equipment includes a creel 1, a yarn row device 2, a static elimination device 3, a yarn row bar 4 and a traction roller 5 arranged in sequence, wherein the yarn The rack includes a creel frame body 11 with three compartments, three layers of spindles 12 installed on the creel frame body 11, the number of spindles installed on each layer is 42, and fiber rolls 13 fixed on the spindles are located on each layer of spindles. The front tooth nozzle yarn discharge plate a14, the tooth nozzle yarn discharge plate a14 is a steel plate with uniform yarn discharge through holes 15. When production starts, the yarn of the fiber roll is drawn out, passes through the yarn-discharging through-hole 15 of the corresponding tooth nozzle yarn-discharging plate, and enters the yarn-discharging device 2 .

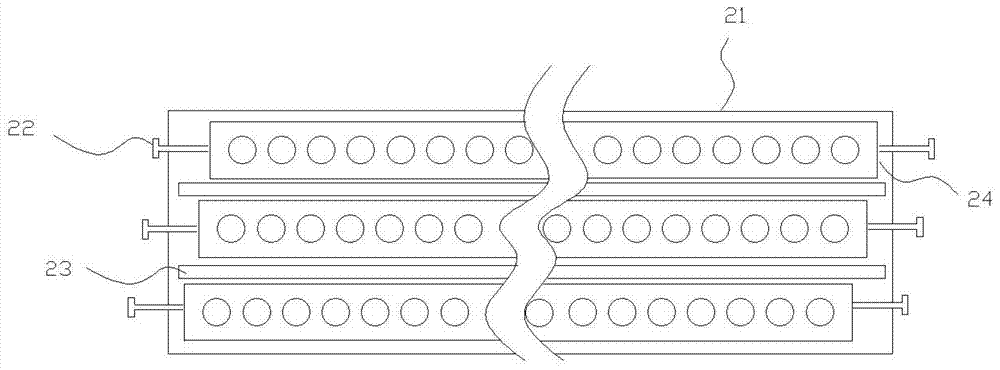

[0029] figure 2 It is a 3-layer yarn a...

Embodiment 2

[0033] A yarn spreading device, comprising a creel, a yarn arrangement device, a static elimination device, a yarn arrangement bar and a traction roller arranged in sequence. The interlayer provided on the creel body is 1 layer, on which 100 spindles are installed, the fiber rolls fixed on the spindles, the tooth mouth yarn discharge plate a located in front of each layer of spindles, and the tooth mouth yarn discharge plate a It is an aluminum plate with evenly arranged yarn through holes.

[0034] The said yarn arranging device has one layer, including a yarn arranging frame body, a tooth mouth yarn arranging plate b, a fixing screw for the tooth mouth yarn arranging plate b, and a scale fixed on the frame body. The tooth nozzle yarn-discharging plate b is an aluminum plate with uniform through holes, its position can move left and right in the slot, and it is measured by a scale fixed on the yarn-discharging frame body, and fixed by fixing screws. The yarn drawn out from t...

Embodiment 3

[0037] A yarn spreading device, comprising a creel, a yarn arrangement device, a static elimination device, a yarn arrangement bar and a traction roller arranged in sequence. There are 10 layers of compartments arranged on the creel frame body, and one spindle is installed on each layer, and the tooth nozzle yarn-discharging plate a in front of each layer of spindles is an aluminum-chromium alloy plate with uniform yarn-discharging through holes.

[0038] The yarn arranging device includes 10 layers of slots that can be inserted into the yarn arranging plate b of the tooth nozzle, and the yarn arranging plate b of the tooth nozzle is set in the slots of each layer, and the yarn arranging plate b of the tooth nozzle is provided with uniform through holes Aluminum-chromium alloy plate, all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com