Engine cylinder cover shield and crankcase ventilation system

A technology of engine cylinder head and shield, which is applied in the direction of crankcase ventilation, engine components, machine/engine, etc., can solve the problem of unsatisfactory separation effect, solve the problem of hose water vapor freezing, reduce noise, improve oil and gas prediction The effect of the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

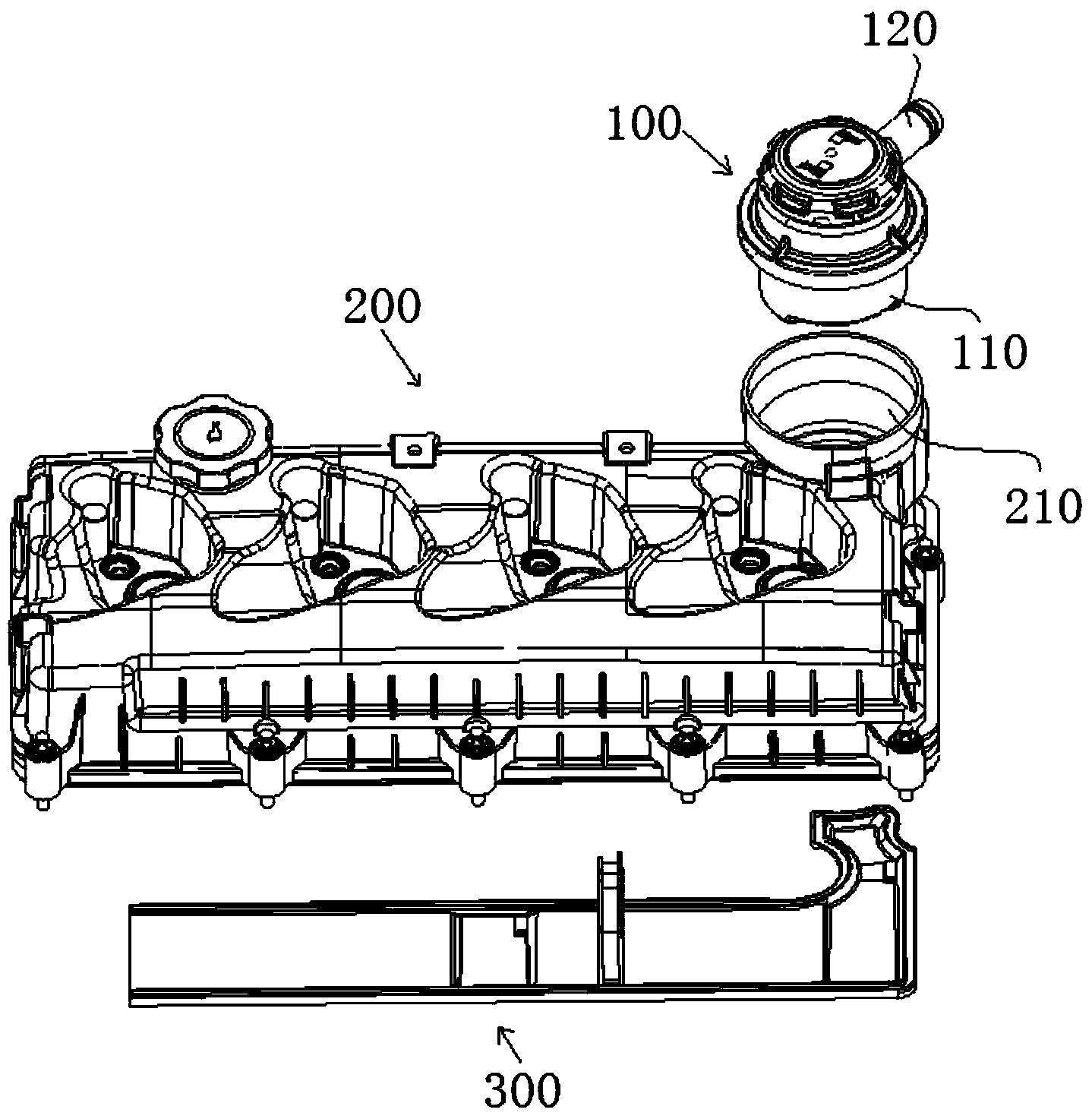

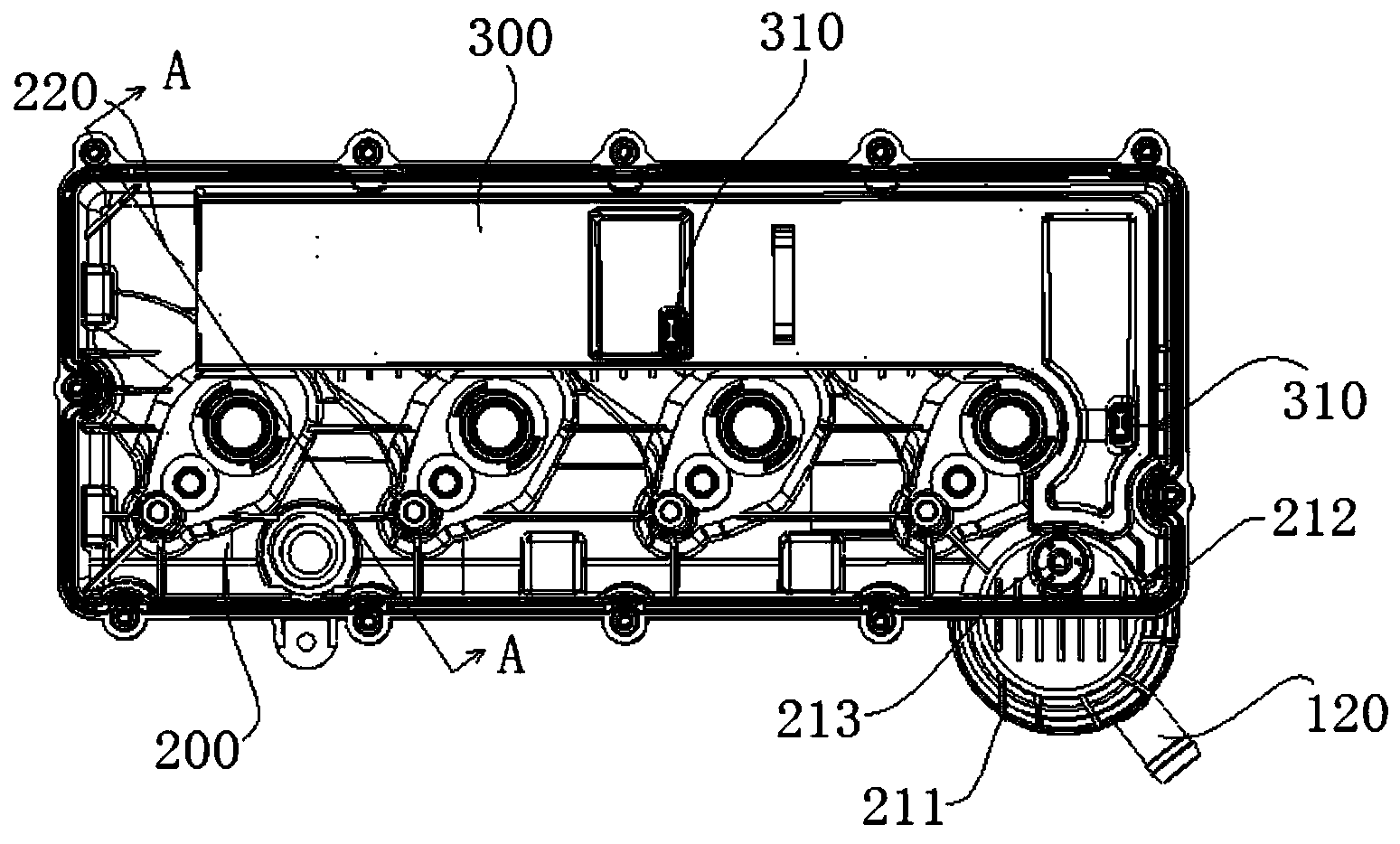

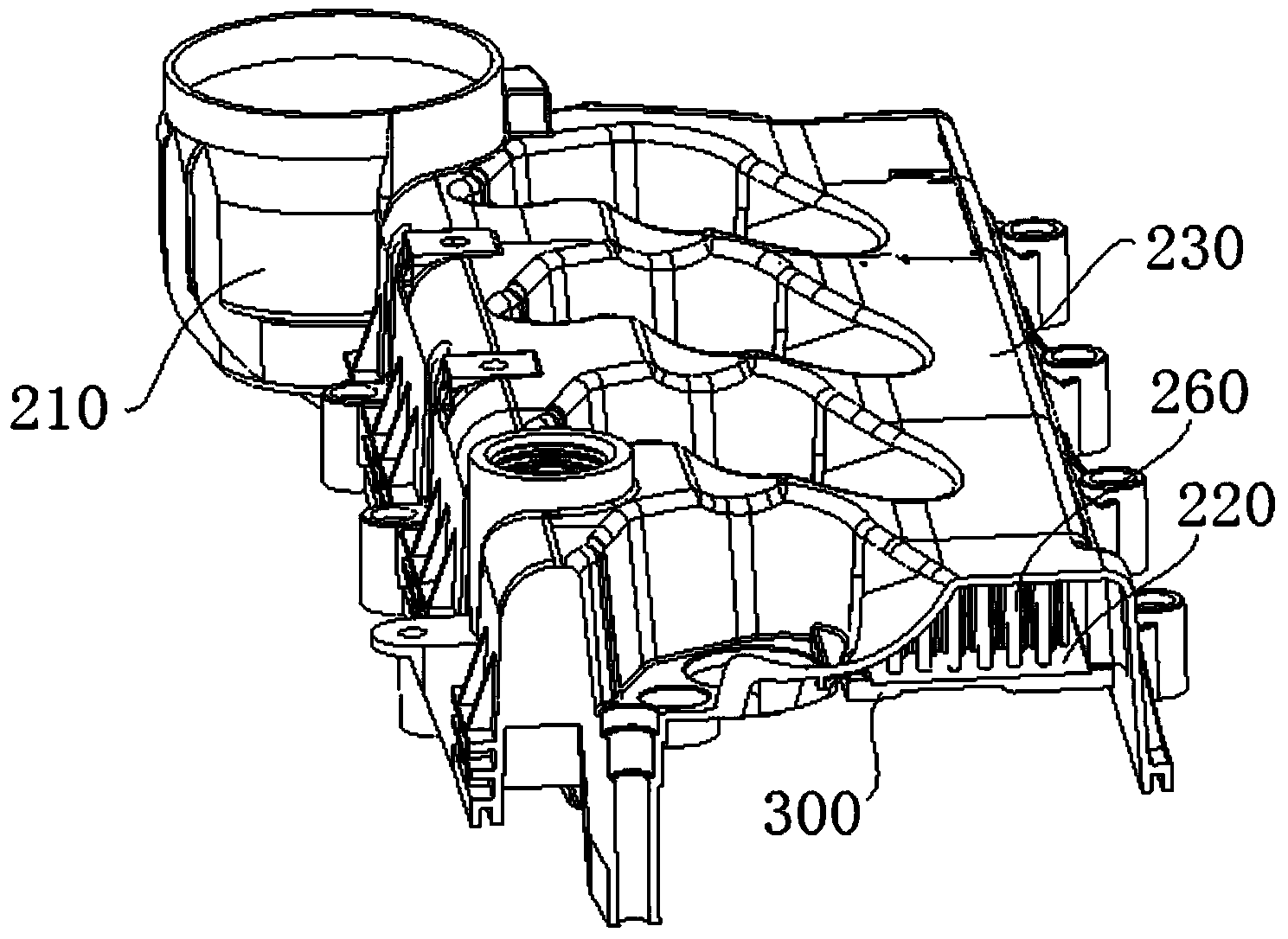

[0034] refer to figure 1 , The crankcase ventilation system in this embodiment mainly includes three parts: the oil-air separator 100 , the guard body 200 and the cover plate 300 . The shield body 200 and the cover plate 300 are snapped together to form the engine cylinder head shield, and the specific internal structure of the engine cylinder head shield will be described below. An oil-gas separator socket 210 is integrally formed on the shield body 200, and the oil-gas separator 100 is installed in the oil-gas separator socket 210, that is to say, the shell 110 of the oil-gas separator 100 is partially or completely located in the oil-gas separator socket. The inside of the seat 210, while the air outlet pipe 120 is exposed outside.

[0035] In the following description, the side facing the engine cylinder head and cylinder block is regarded as the inside, and the side facing away from the engine cylinder head and cylinder block is regarded as the outside.

[0036] refer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com