Casing pipe for pipe connection

A technology for connecting casings and casings, applied in the direction of pipes/pipe joints/fittings, sleeve/socket connections, passing components, etc. The effect of low counterpart difficulty and saving time in connecting pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

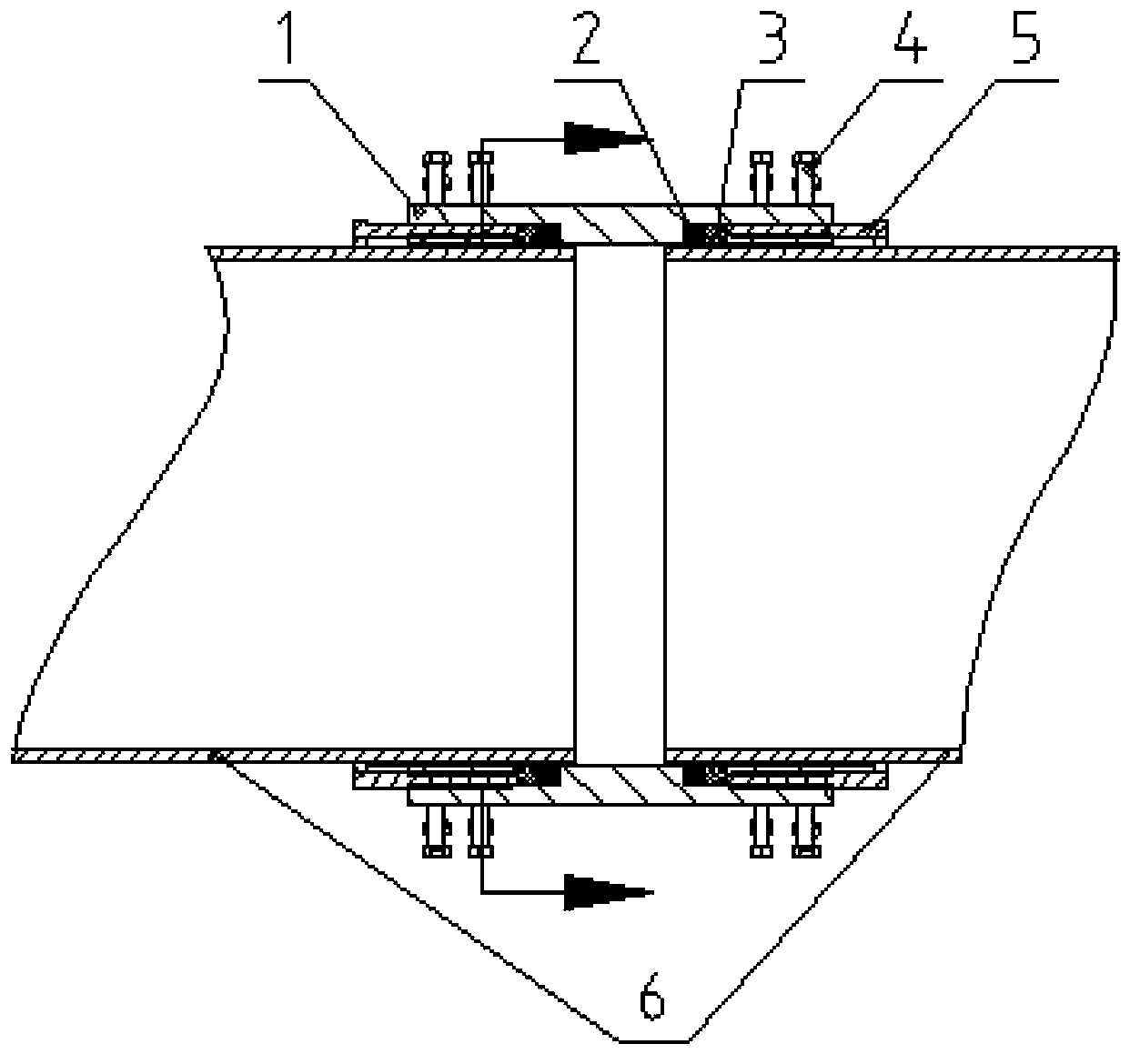

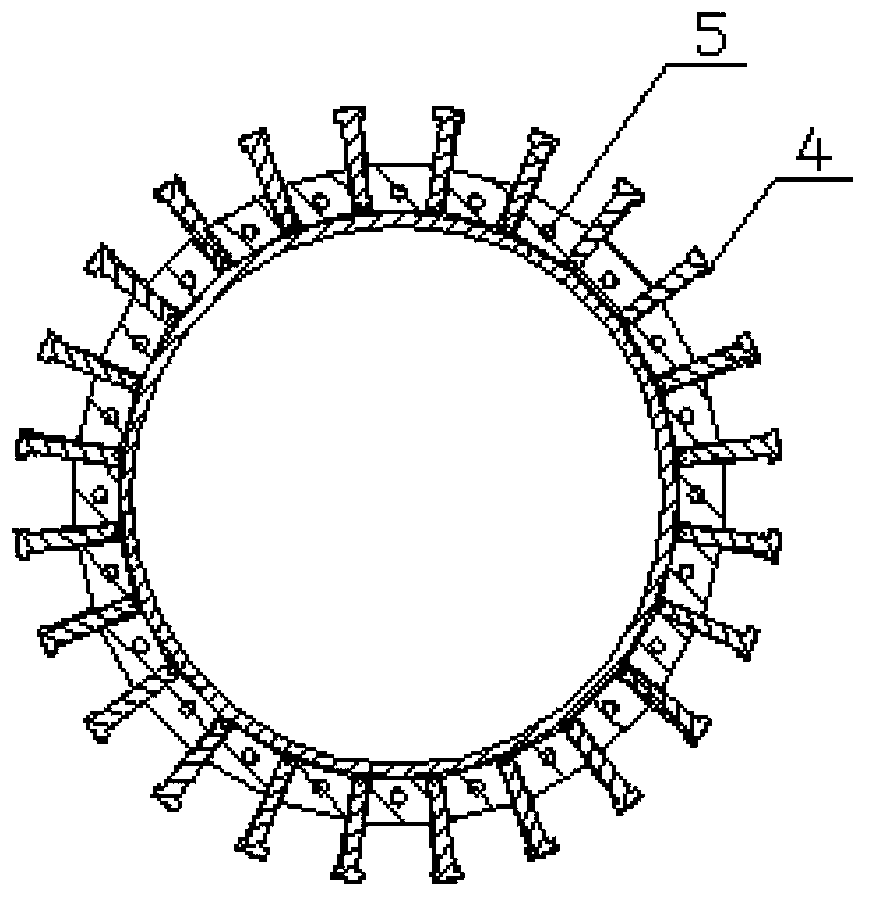

[0012] The pipe connection casing includes casing 1, rubber sealing ring 2, compression steel ring 3, tightening bolt 4 and compression bolt 5:

[0013] The inner diameter of the cylindrical casing 1 is the same as the outer diameter of the pipe 6; a circumferential assembly ring groove is provided in the middle of the inner peripheral surface of the casing 1, and a rubber sealing ring 2 and a compression steel ring 3 are arranged in the groove; On both ends of the surface, there is a ring of axial holes connected to the circumferential assembly ring groove, and the compression bolts 5 are connected in the holes, and the small square head bolts of the compression bolts 5 touch the top of the compression steel ring 3; Both ends of the outer peripheral surface are provided with two circles of radial through holes, and the tightening bolts 4 are connected in the holes.

[0014] The connection process between the pipe connecting sleeve and the pipe is as follows:

[0015] First, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com