Roaster waste heat collector

A waste heat collection and roasting furnace technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of wasting resources, increasing the temperature of the working environment, wasting manpower, material and financial resources, etc., so as to save production costs, facilitate popularization and application, and guarantee The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

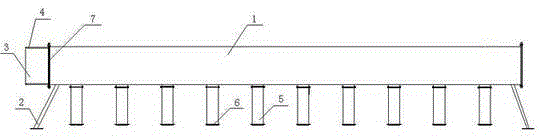

[0015] Accompanying drawing is the specific embodiment of the present invention.

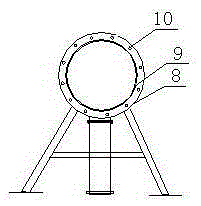

[0016] like figure 1 The roaster waste heat collector of the present invention shown in the present invention includes a cylinder body 1, the two sides of the cylinder body 1 are fixed by brackets 2, a heat outlet 3 is provided on one side of the cylinder body 1, and a butt joint groove 4 is arranged on the wall of the heat outlet 3 The lower end of the cylinder 1 is evenly provided with a number of heat-insulating metal hoses 5, the lower end of the heat-insulating metal hose 5 is provided with a fire channel sealing head 6, and the side of the cylinder 1 close to the heat outlet 3 and the other side of the cylinder 1 are equipped with The connection and sealing ring 7, the connection and sealing ring 7 includes the outer layer sealing groove 8 and the inner layer sealing groove 9, and the connection and sealing ring 7 is fixed by bolts and nuts 10.

[0017] When in use, place the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com