Metering a flow of a fluid through a cylindrical tube section

A technology for measuring device and fluid flow, applied in the direction of measuring device, liquid/fluid solid measurement, measuring flow/mass flow, etc. Avoid distracting and disruptive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

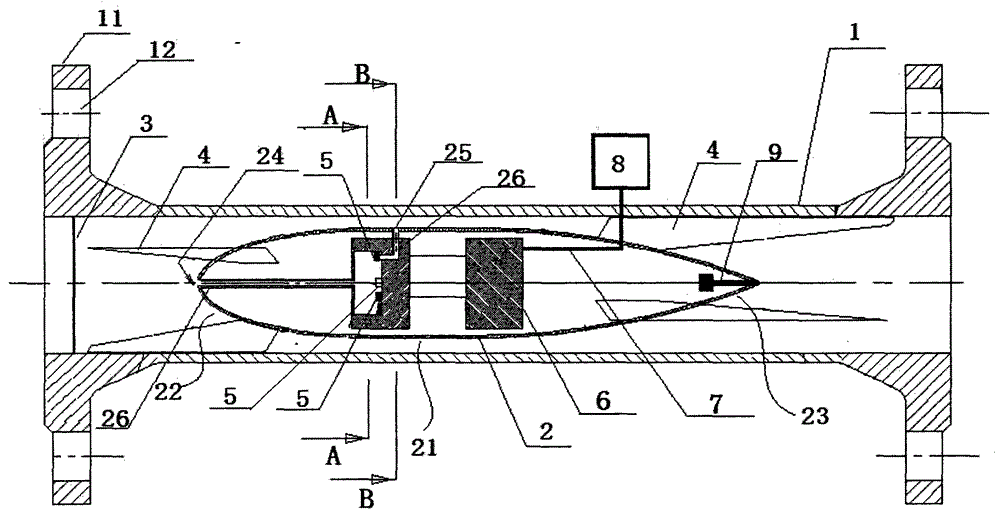

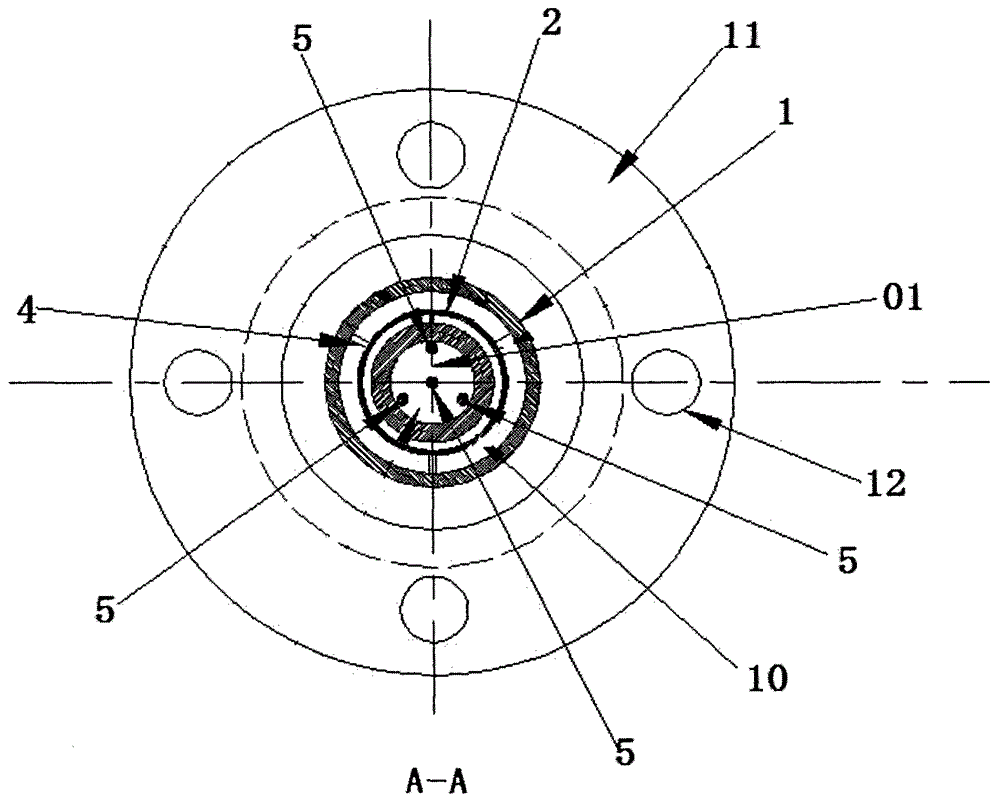

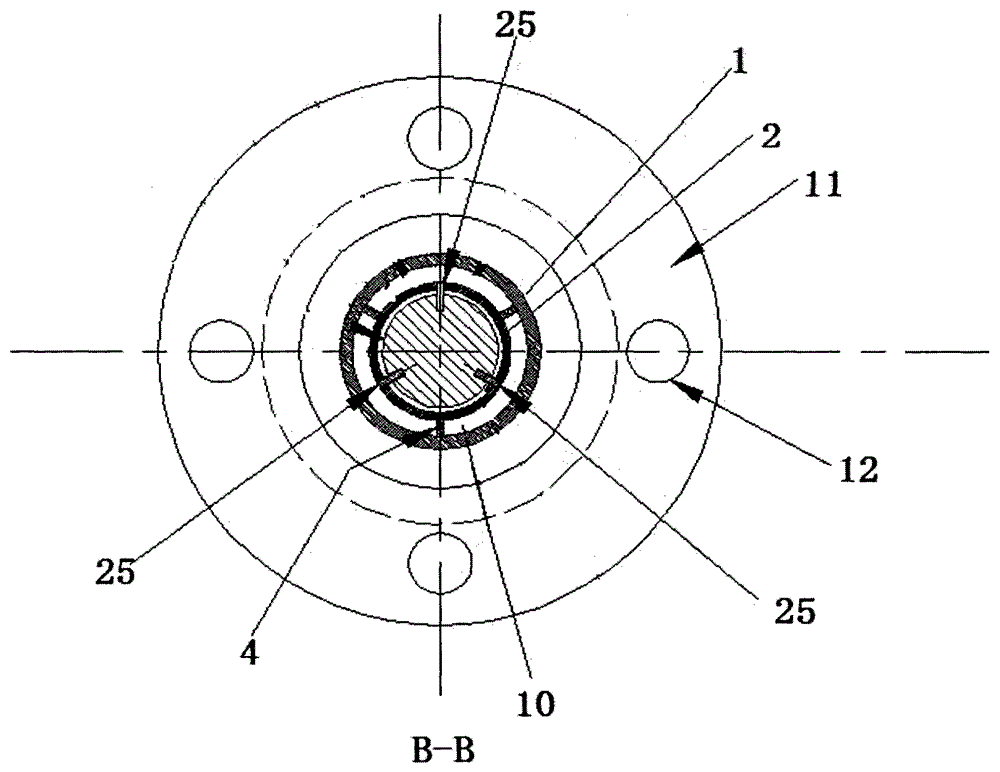

[0037] Figure 1 to Figure 3 In the shown embodiment, the two ends of the measuring tube 1 are sealed and welded with flanges 11 respectively, and the flange 11 has bolt holes 12. When measuring, the device of the present invention can be connected to the device through the bolt holes 12 on the flange 11. It is connected to the pipeline to be tested, and makes the front end 22 of the throttling part 2 face the direction of fluid flow. An annular fluid channel is formed between the cylindrical middle section 21 of the throttling part 2 of the streamline body and the inner wall of the measuring tube 1 . The filter screen 3 can play the effect of preventing impurities from accumulating and blocking.

[0038] The front end 22 of the throttling member 2 is ellipsoidal, and the rear end 23 is curved and conical, which can be more effective in avoiding the generation of fluid vortices, and facilitate the setting of more favorable pressure extraction points to obtain more accurate pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com