Rapid response thermocouple temperature sensor

A thermocouple sensor and temperature sensor technology, applied in the field of sensing, can solve the problems of easy open circuit of temperature sensing point, poor dynamic measurement effect, long production cycle, etc., to avoid long curing time, avoid response lag, and shorten response time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

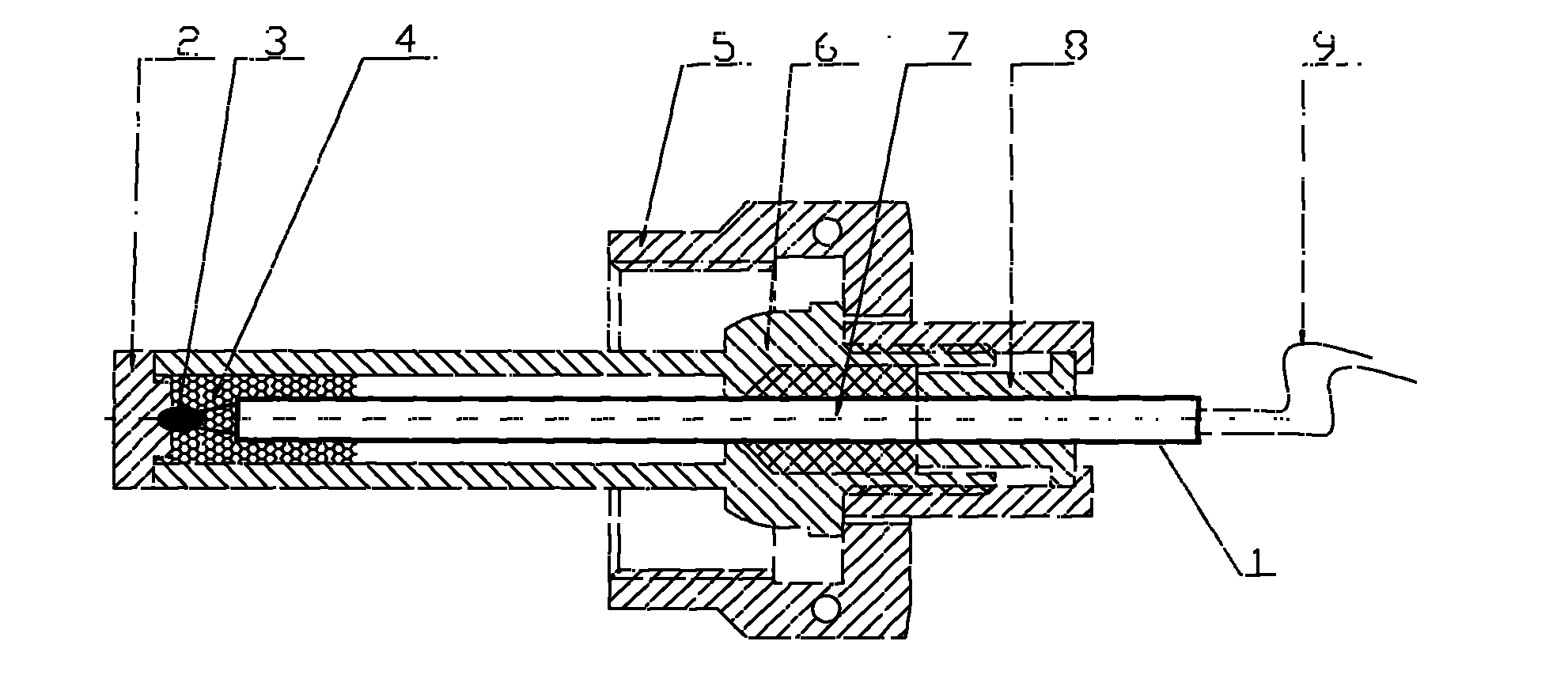

[0015] Embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0016] The thermocouple wire 9 forms the thermocouple temperature-sensing point 3 by spot welding, and one end of the lead wire of the thermocouple wire 9 passes through the double-hole corundum tube 1 and inserts it into the sealed ball socket 6 .

[0017] Fill the thermally conductive filling material 4 around the temperature sensing point 3 of the temperature sensor thermocouple manufactured through the above process, and then weld it to the head 2, and then weld the head 2 to the long rod end of the sealing ball seat. Assemble the positioning compression block 7, the connecting nut 5 and the compression ring 8 sequentially on the ball end of the sealing ball seat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com