A Synchronous Control Method for Two-axis Drive Electric Vehicle Hardware-in-the-Loop Test System

A test system and electric vehicle technology, applied in electrical testing/monitoring, vehicle testing, machine/structural component testing, etc., can solve the problem that the driver cannot control the vehicle in real time, dual-motor drive and braking coordination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described in conjunction with the following examples.

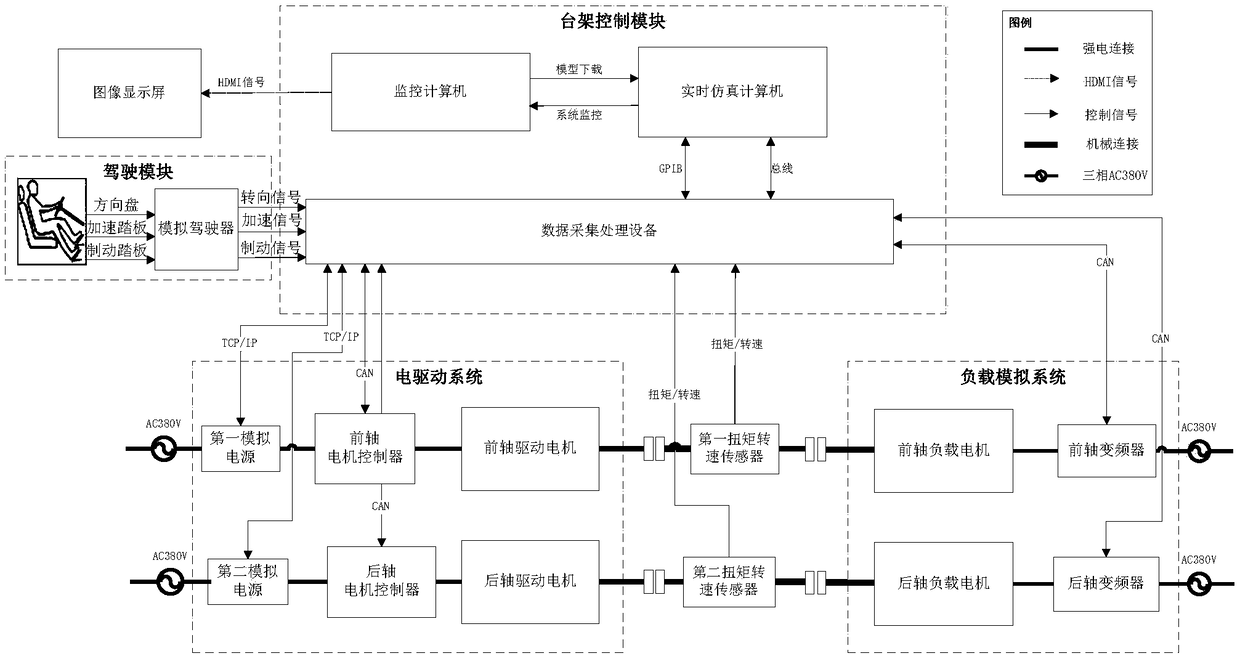

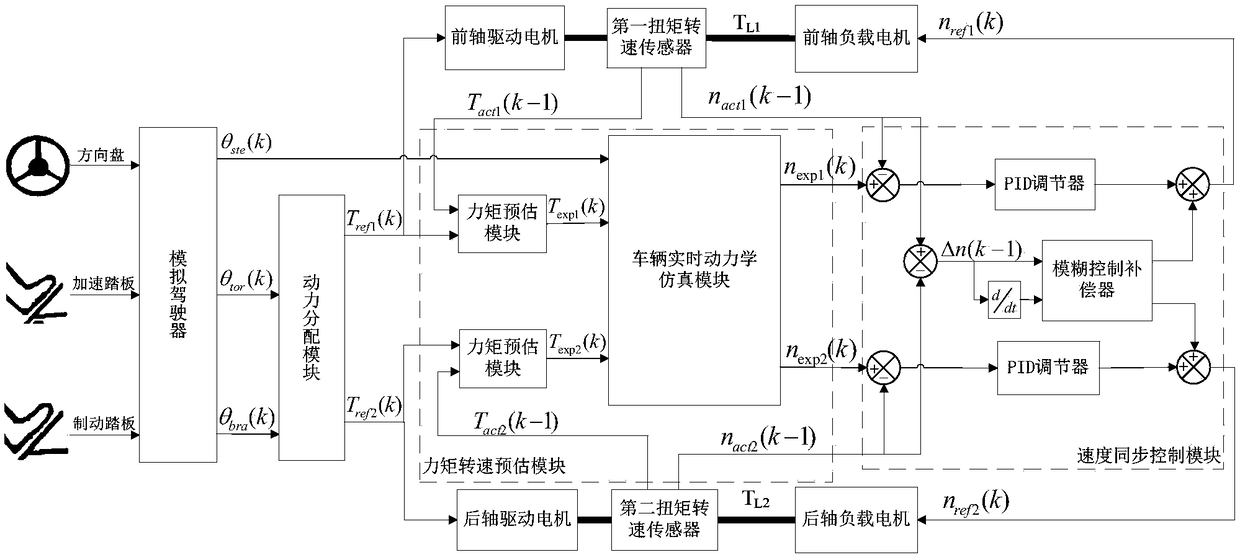

[0032] Such as figure 1 As shown, a dual-axis drive electric vehicle hardware-in-the-loop test system includes a driving module, a bench control module, an electric drive module, a load simulation system and an image display. The driving module includes a simulated vehicle for the driver to control, including an accelerator pedal, a brake pedal and a steering wheel. The platform control module includes a monitoring computer, a real-time simulation computer and data acquisition and processing equipment. The monitoring computer establishes virtual driving conditions, virtual road conditions, torque and speed estimation modules, and speed synchronization control modules through CarSim / LabVIEW; The estimation module and the speed synchronization control module are downloaded to the real-time simulation computer, and the data interaction between the monitoring computer and the real-tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com