Elastic waist online breaking transfer device and method

A technology of elastic waist circumference and transfer device, which is applied in the fields of medical science, clothing, underwear, etc., can solve the problems of high processing precision requirements of equipment components, affecting production efficiency, and adverse production costs, and achieves control and processing that is beneficial to production costs. The effect of fast speed and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

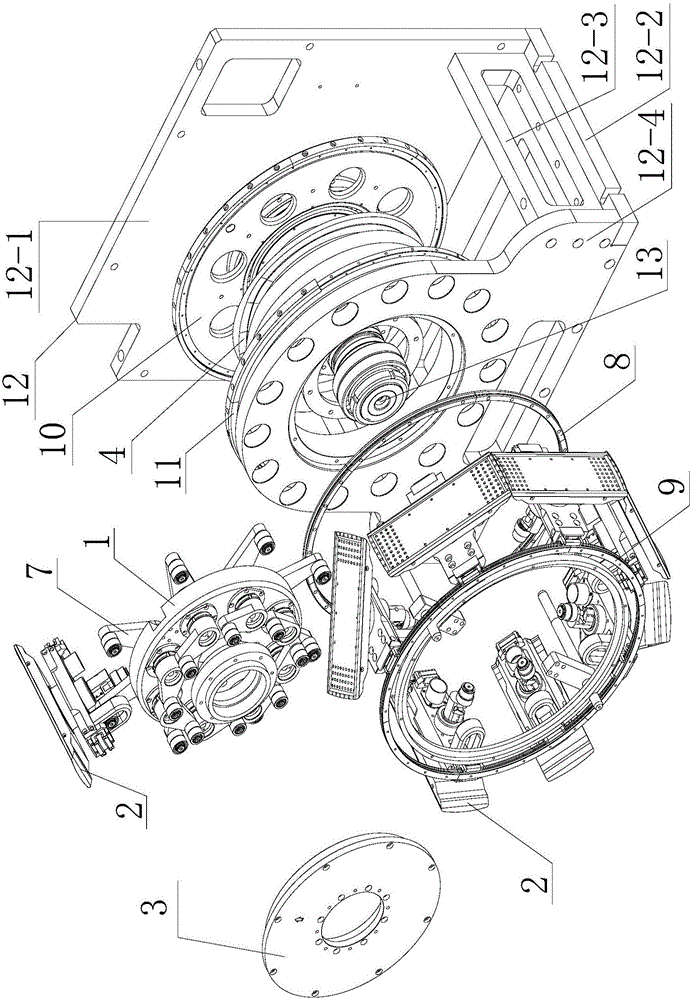

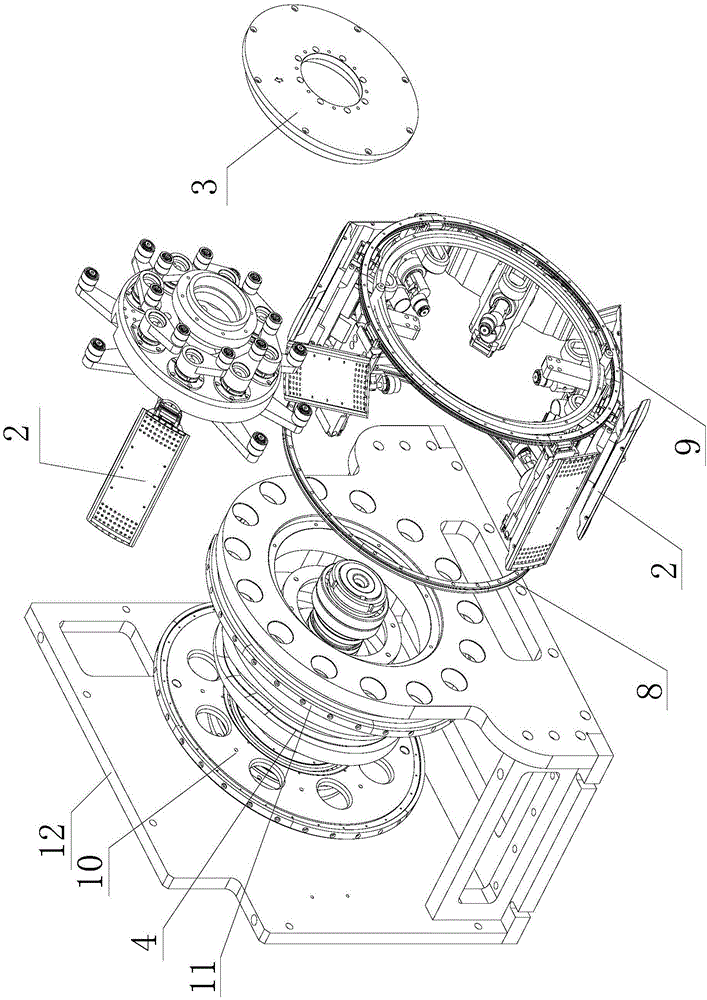

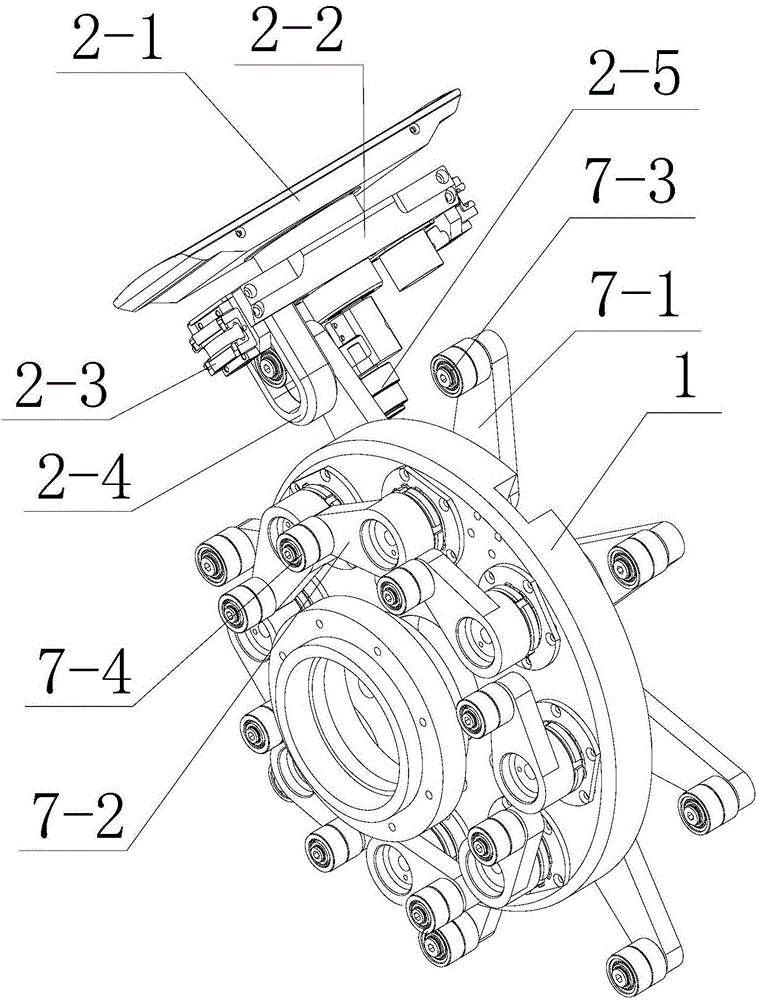

[0036] In this embodiment, a rail-type replaceable cam elastic waist online pull-off transfer device, such as figure 1 or figure 2 As shown, it includes a main drive disc 1, an adsorption turntable unit 2, a speed change cam 3 and a reversing cam 4. The speed change cam is arranged on one side of the main drive disc, and the reversing cam is arranged on the other side of the main drive disc. There are multiple adsorption turntable units distributed on the periphery; such as Figure 4 As shown, the speed change cam is provided with a speed change track groove 5, and the speed change track groove is a bidirectional convex curve; as Figure 5-7 As shown, there is a reversing track groove 6 on the reversing cam; image 3 As shown, the main drive disc is provided with a plurality of swing rod assemblies 7, and one end of each swing rod assembly is correspondingly connected with an adsorption turntable unit, and the other end of each swing rod assembly is embedded in the speed ch...

Embodiment 2

[0045] In this embodiment, the device described in Embodiment 1 realizes a method for online pulling and transferring of elastic waist circumference. After the unit absorbs the elastic non-woven fabric, it turns around the center of the main drive disc to generate accelerated rotation, and quickly distances itself from the position where the adsorption turntable unit absorbs the elastic non-woven fabric, thereby causing a pulling effect on the elastic non-woven fabric; as the adsorption turntable unit rotates The main drive disk continues to rotate, and the adsorption turntable unit is gradually rotated by 90° by using the change of the reversing track groove of the reversing cam, and then compounded with the composite drum outside the elastic waistline pull-off transfer device, and the elastic non-woven belt is passed through the composite drum. out.

[0046] The above-mentioned elastic waist line breaking transfer method specifically includes the following steps:

[0047] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com