High-response injection molding machine servo pump cylinder injection system

A technology of injection system and servo pump, which is applied in the system field of high-response injection molding machine servo pump driving hydraulic cylinder, can solve the problems of slow response speed, long pipeline, pressure loss along the way, etc., so as to improve the response speed and reduce the pressure along the way. The effect of loss, ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

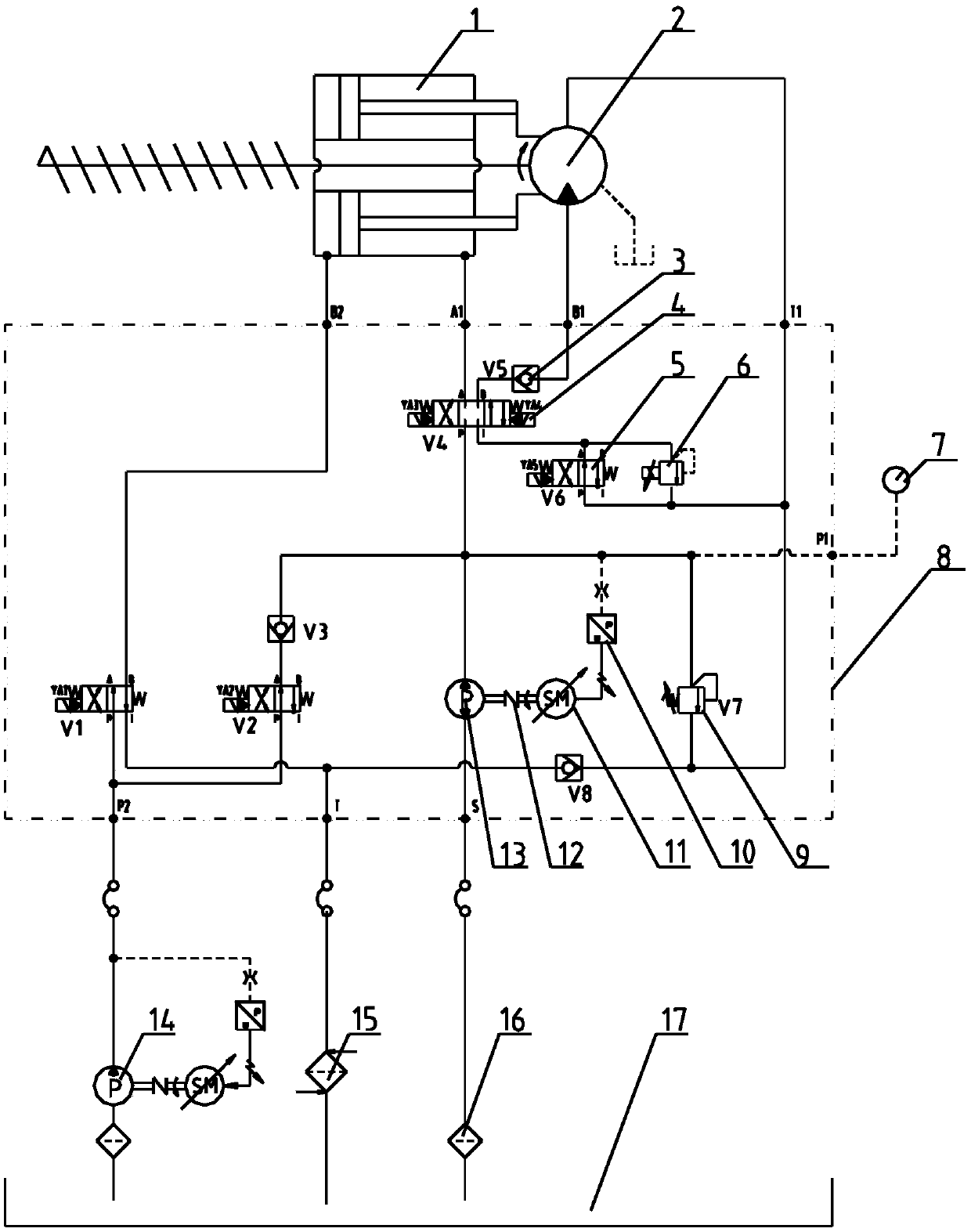

[0014] The implementation of a high-response injection molding machine servo pump cylinder injection system provided by the present invention will be further described below with reference to the accompanying drawings, which is mainly composed of an oil tank 17, a motor oil pump assembly, a control valve plate 8, and an oil cylinder 1. Among them, the motor oil pump assembly is composed of servo motor 11, coupling 12, servo pump 14 and filter 16; the control valve plate 8 is composed of check valve 3, three-position four-way electromagnetic reversing valve 4, two-position four-way electromagnetic reversing Valve 5, proportional valve 6, pressure gauge 7, overflow valve 9, two-way quantitative servo pump 13 and other components. The servo motor 11 is connected with the servo pump 14 through the coupling 12, and the high-pressure hydraulic oil enters the oil inlet port of the servo pump 14 from the oil tank 17 through the filter 16; the oil outlet port of the servo pump 14 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com