Four-terminal-method high-value capacitor impedance measuring device and measuring method thereof

A technology for measuring device and capacitance impedance, which is applied in the direction of measuring device, measuring electrical variables, measuring resistance/reactance/impedance, etc., and can solve problems such as large measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

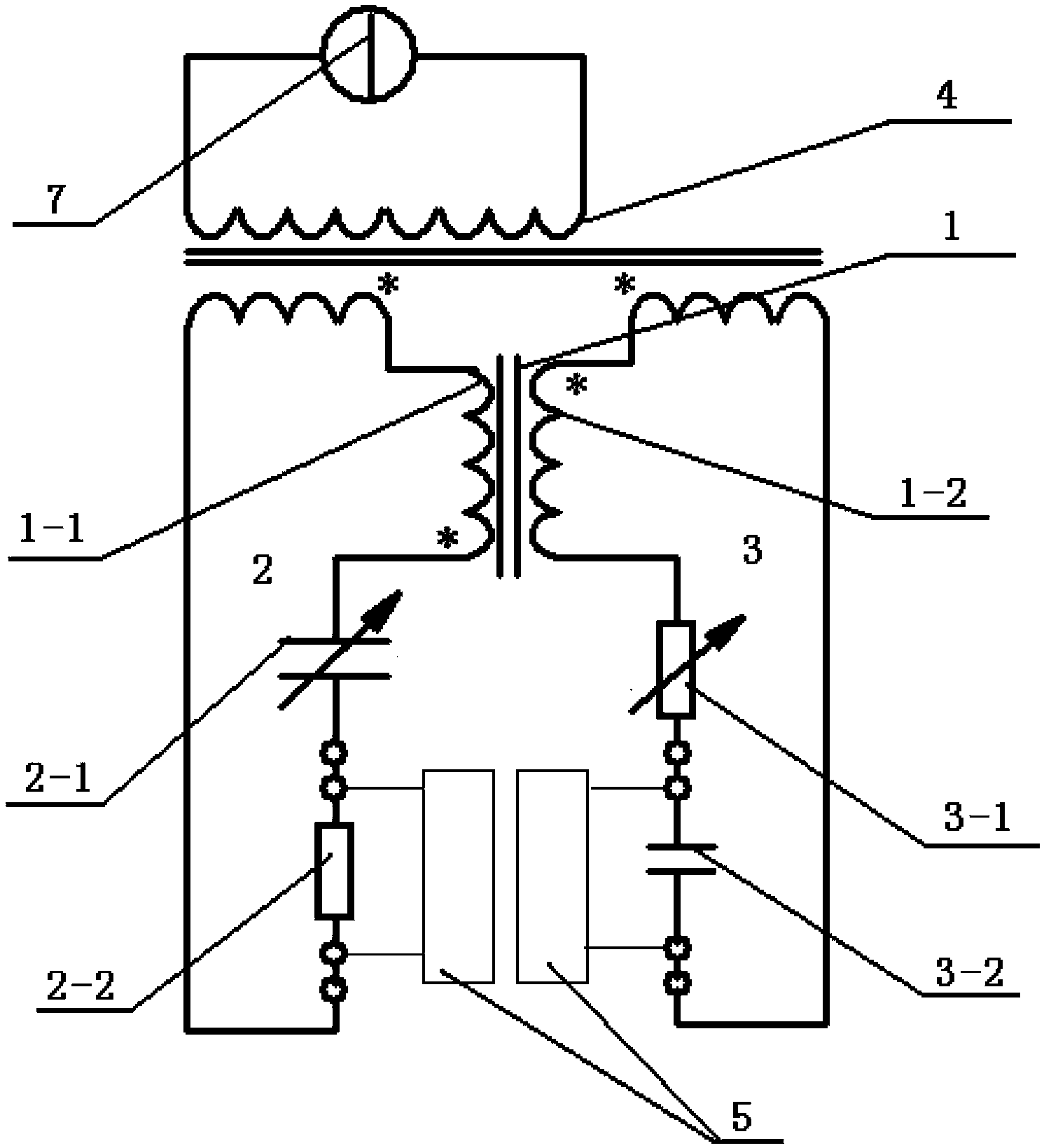

[0135] according to image 3 , Figure 4 , Figure 5 as shown,

[0136] A four-terminal method high-value capacitive impedance measuring device, the measuring device includes an induction shunt 1, an isolation transformer 4, a measurement loop A2, a measurement loop B3, a digital voltmeter 5, and a power supply 7;

[0137] The induction shunt 1 includes a winding A1-1 and a winding B1-2;

[0138] The first end of the winding A1-1 is connected to the current input end of the measurement circuit A2, and the tail end is connected to the current output end of the measurement circuit A2;

[0139] The first end of the winding B1-2 is connected to the current output end of the measurement circuit B3, and the tail end is connected to the current input end of the measurement circuit B3;

[0140] The turns ratio of the winding A1-1 and the winding B is 1:1;

[0141] The measurement circuit A2 includes a capacitor box 2-1, a standard resistor 2-2 and the winding A1-1 connected in se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com