Wall cement mortar plastering and rendering machine

A technology of cement mortar and plastering machine, which is applied in the direction of construction and building construction, which can solve the problems of slow speed and manual workload, and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

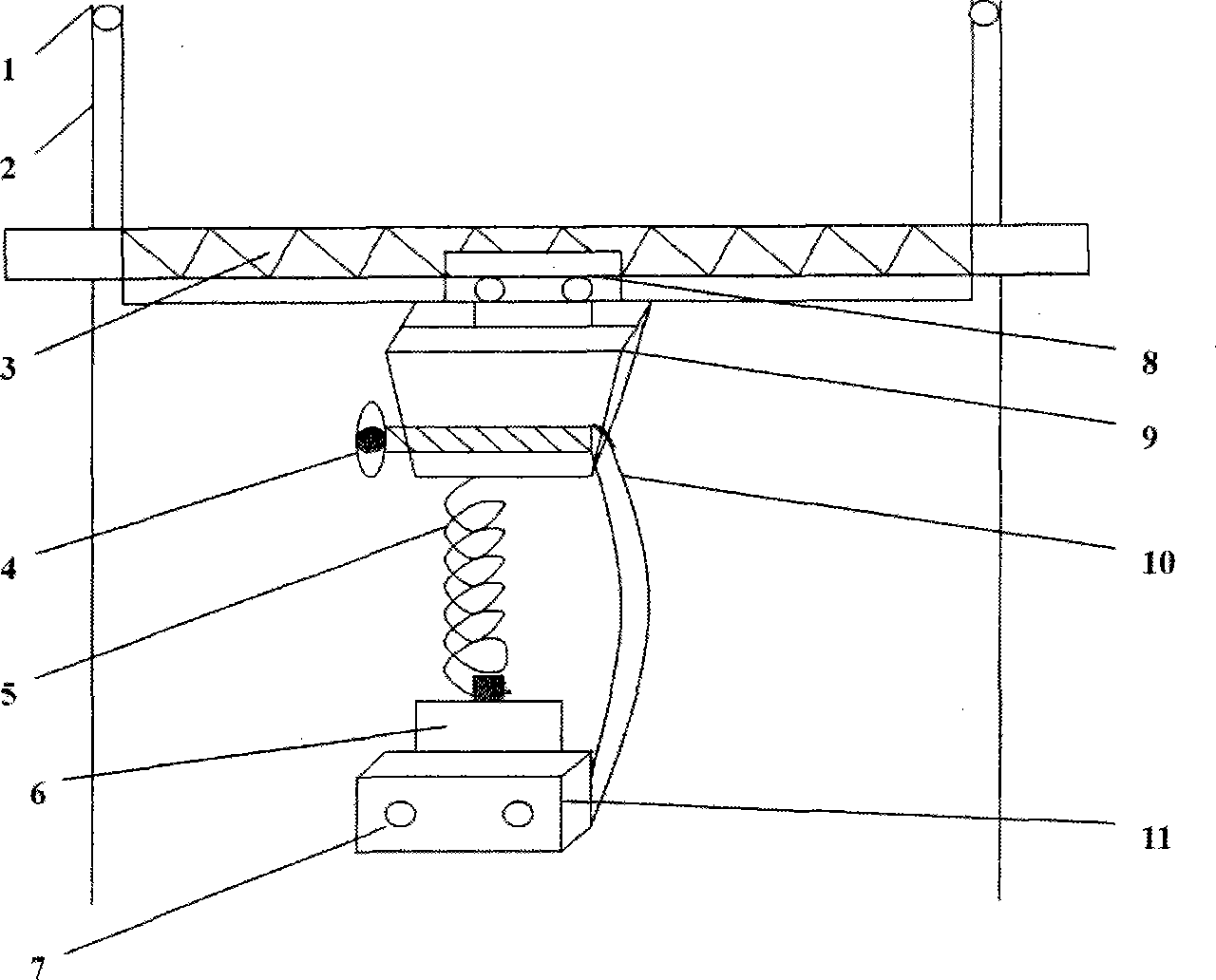

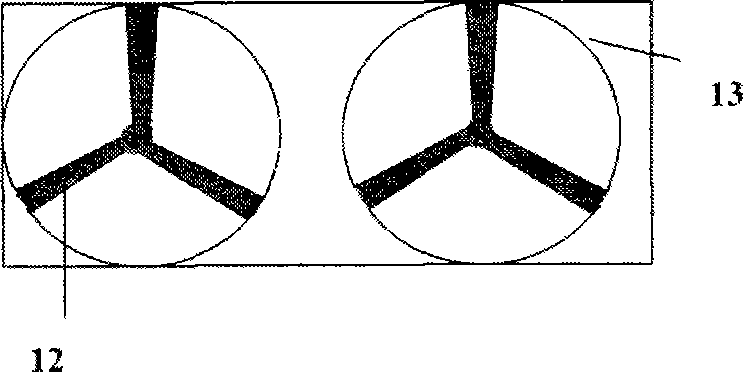

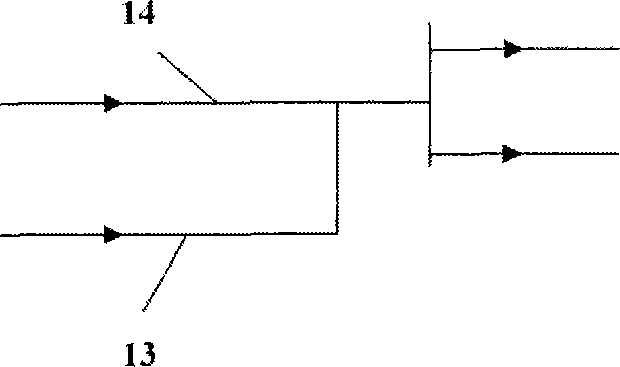

[0013] exist figure 1 Among them, the lifting of the bridge frame 3 is realized by the winch on the crane rotating and dragging the cable 2. The bridge frame 3 is outside the cable 2 to prevent the bridge frame 3 from swinging and touching the wall. The hopper 9 is suspended on the trolley 8 and can move left and right on the bridge frame 3. , the cement mortar in the hopper 9 is under the rotation of the screw propulsion rod 4, the cement mortar is pushed into the hose 10, the lower end of the hose 10 is connected with the cement mortar plasterer 11, and the cement mortar is under the action of the air pump 6, the air pump 6 The medium gas sprays the cement mortar onto the wall, and the rotary trowel rotating device 7 is driven by the motor to rotate the trowel at a high speed. 5 Lift the air pump 6 and the cement mortar plasterer, the switch is on the handle, only need to press the switch up, down, left, and right, all controlled by machinery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com