High temperature test agent sealer

A high-temperature, seal-testing technology, applied to valve devices, valve details, engine components, etc., can solve problems such as long residence time of seal-testing agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

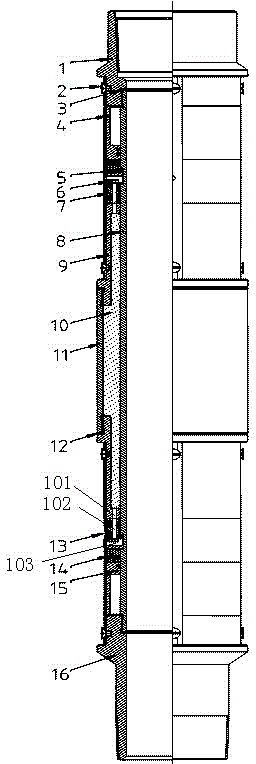

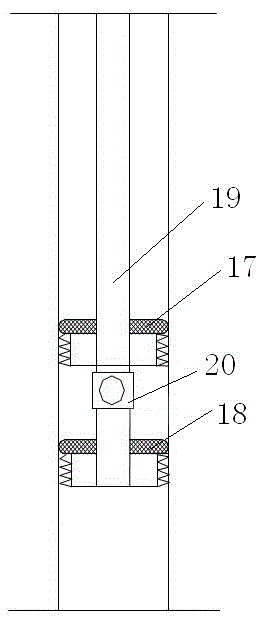

[0019] Embodiment 1 of the high-temperature identification agent sealing device of the present invention, such as Figure 1-2 As shown: the high-temperature seal tester, including a central tube 8, the inner diameter of the central tube 8 is 95mm, and the periphery of the central tube 8 is provided with a storage chamber 10 for storing the seal test reagent, and the seal test reagent is installed in the storage chamber 10 , the seal identification agent is solid sodium chloride. The cavity wall of the storage cavity 10 is provided with an identification agent outflow channel 101 for the sealing agent to flow into the sealed space formed by the packer to be tested, and the identification agent outflow channel 101 is arranged at the upper end of the storage cavity 10 cavity and the lower end, the switching mechanism is a temperature control valve, the temperature control valve includes a valve seat with a first flow hole communicating with the outflow channel of the identificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com