High-viscosity rapid drying machine

A fast-drying, high-viscosity technology, used in dryers, drying solid materials, drying, etc., can solve the problems of inability to dry high-viscosity and high-humidity materials, continuous production, and low dryer efficiency, and increase drying contact. Area, sufficient contact with hot air, and the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

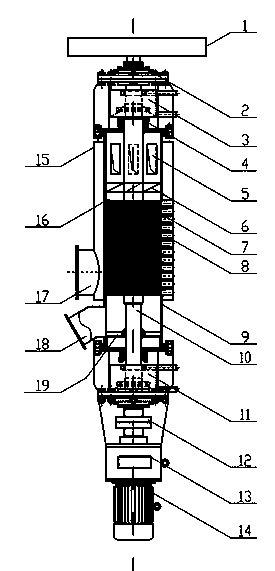

[0033] figure 1 and Figure 4 -6 shows a high-viscosity quick dryer, including the main body of the vertical dryer. The main body of the vertical dryer includes an inner shell 9, and the center of the inner shell 9 is provided with a main shaft 10. The main shaft 10 is supported and fixed by the bearing group 2 outside the two ends of the inner shell 9, and the two ends of the inner shell 9 are also equipped with shaft seals. 4.

[0034] There is also an upper cooling water tank 3 between the shaft seal 4 and the bearing group 2 at one end, and the inner shell 9 in this section is covered with an insulation layer; the lower cooling water tank 11 is also provided between the shaft seal 4 and the bearing group 2 at the other end. The inner shell 9 of the section is covered with an insulation layer.

[0035] The drive motor 14 is also connected to the input end of the main shaft 10 after passing through the gear box 13 and the shaft coupling 12 .

[0036] The middle part of t...

Embodiment 2

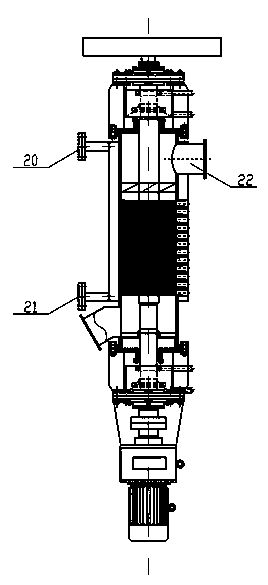

[0047] figure 2 and Figure 4 -6 is a high-viscosity rapid dryer, which is a medium-temperature (100-250°C) dryer, suitable for high-viscosity and high-humidity materials such as amides with a molecular weight of 1 million to 2 million, sprinkled grains, and pomace. The drying medium is Hot liquid such as hot oil, hot water, can also be hot water vapor.

[0048] The difference between this embodiment and embodiment 1 only lies in:

[0049] (1) There is no inner air inlet in this embodiment;

[0050] (2) The air inlet 17 in Embodiment 1 is replaced by the heat transfer oil inlet, hot water inlet or condensed water outlet 21 in this embodiment;

[0051] (3) The upper end of the jacket 15 and the upper part of the turbofan 6 are provided with a heat transfer oil outlet, a hot water outlet or a steam inlet 20 communicating with the inner cavity of the jacket 15 .

[0052] (4) The upper end of the jacket 15 and the upper part of the turbofan 6 are provided with an exhaust gas ...

Embodiment 3

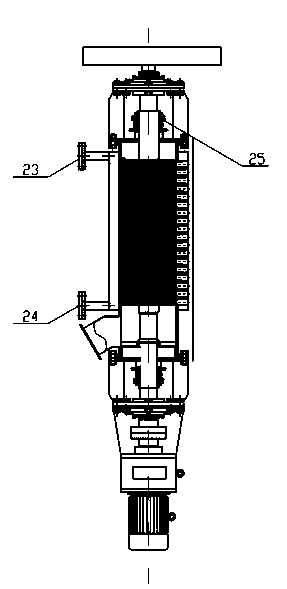

[0055] image 3 , Figure 5 , Image 6 Shown is a high-viscosity quick dryer, which is a low-temperature vacuum type (50-100°C) dryer, suitable for treating amides with a molecular weight of more than 2 million (it will glue if it exceeds 700°C), municipal sludge, etc., which require no odor For high-viscosity and high-humidity materials, the drying medium is hot liquid such as hot water, or hot water vapor.

[0056] The difference between this embodiment and embodiment 2 only lies in:

[0057] (1) There is no upper cooling water tank 3 and lower cooling water tank 11 in this embodiment;

[0058] (2) The shaft seal 4 in embodiment 2 is replaced by the mechanical seal 25 in this embodiment;

[0059] (3) There is no waste gas or secondary steam inlet 22 in this embodiment;

[0060] (4) The heat transfer oil inlet, hot water inlet or condensed water outlet 21 in Embodiment 2 are replaced by hot water inlet or condensed water outlet 24 in this embodiment;

[0061] (5) The he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com