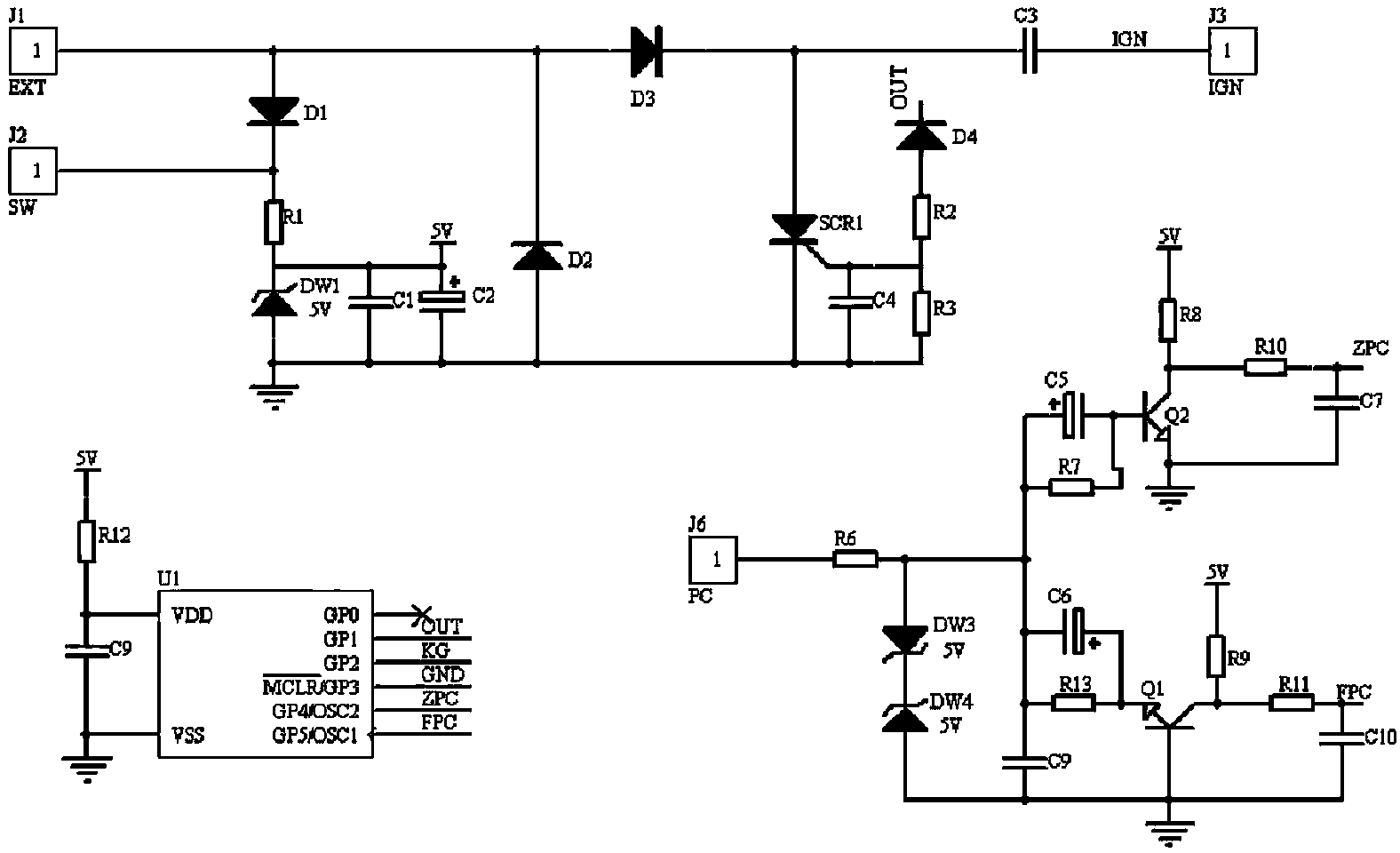

Integrated igniter control circuit

A control circuit and igniter technology, applied in automatic control, automatic control, electrical automatic control, etc., can solve the problems of small ignition energy and high energy consumption, and achieve the effect of large ignition energy and fuel consumption saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] as attached figure 1 As shown, the integrated igniter control circuit of the present invention provides alternating current through the igniter control circuit to realize the ignition of the ignition coil by the magneto. The igniter control circuit includes a microchip, and the microchip is connected with the output end of the ignition coil, wherein the positive pulse signal When it arrives, ZPC provides a signal to the single-chip microcomputer. When the negative pulse arrives, FPC provides a signal to the single-chip microcomputer. The single-chip microchip processes the ZPC and FPC signals to output the OUT signal, thereby controlling the thyristor SCR1 to discharge positively, so that the capacitor C3 stores energy. Release, so as to provide energy to the ignition coil, and the ignition coil transforms the low voltage (400V) into a high voltage (21KV) discharge, ignites the oil-gas mixture in the gasoline engine, and achieves the purpose of ignition;

[0019] The mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com