Throwing type fracturing equipment

A drop-in, fracturing technology, which is applied to weapons accessories, mining fluids, fuzes, etc., can solve problems such as cable knotting, cable damage, and failure to construct, so as to save manpower and material resources, avoid knotting when encountering obstacles, and improve success. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

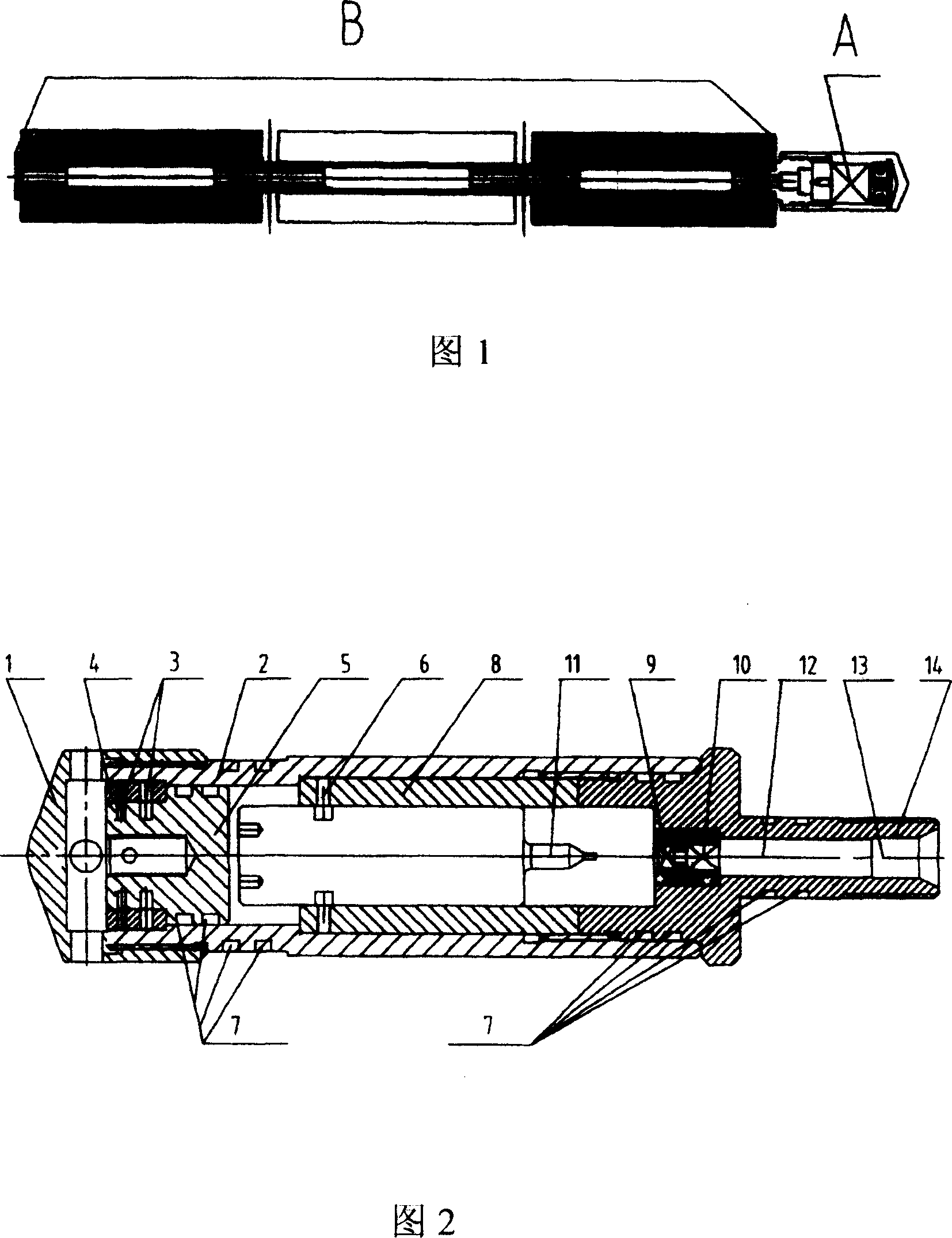

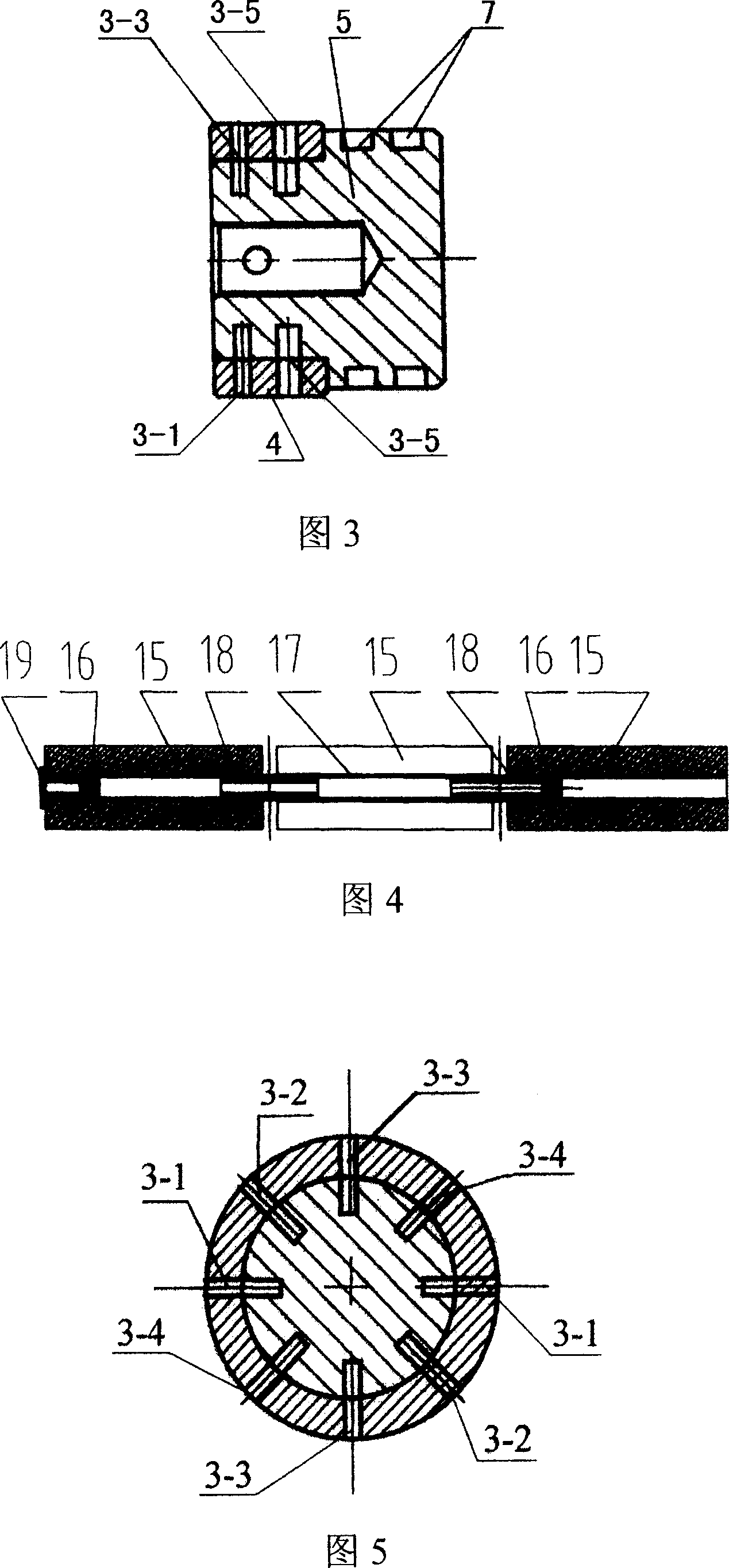

[0022] As shown in Figure 1, the first preferred embodiment of the present invention consists of a pressure igniter A and a high-energy gas generator B. The pressure igniter A is connected with the high-energy gas generator B through the connecting body of its firing mechanism.

[0023] Referring to Fig. 2, the pressure igniter A of this preferred embodiment includes a tail cap 1, a body 2, a pressure release mechanism, a firing pin assembly, and an ignition mechanism. The body 2 is a cylindrical shell made of steel with multiple central stepped through holes, one end of which is provided with an external thread and the other end is provided with an internal thread. The tail cover 1 has internal threads and radial through holes. The pressure release mechanism includes a pressure bearing pin 3, a pressure bearing ring 4 and a piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com