adjustable ejector

The technology of flow device and jet box is applied in the field of suction and negative pressure equipment, which can solve the problems of low nozzle bearing pressure, unadjustable nozzle, twisted orifice, etc., and achieves the effect of good cleaning performance, simplified structure, and improved bearing pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

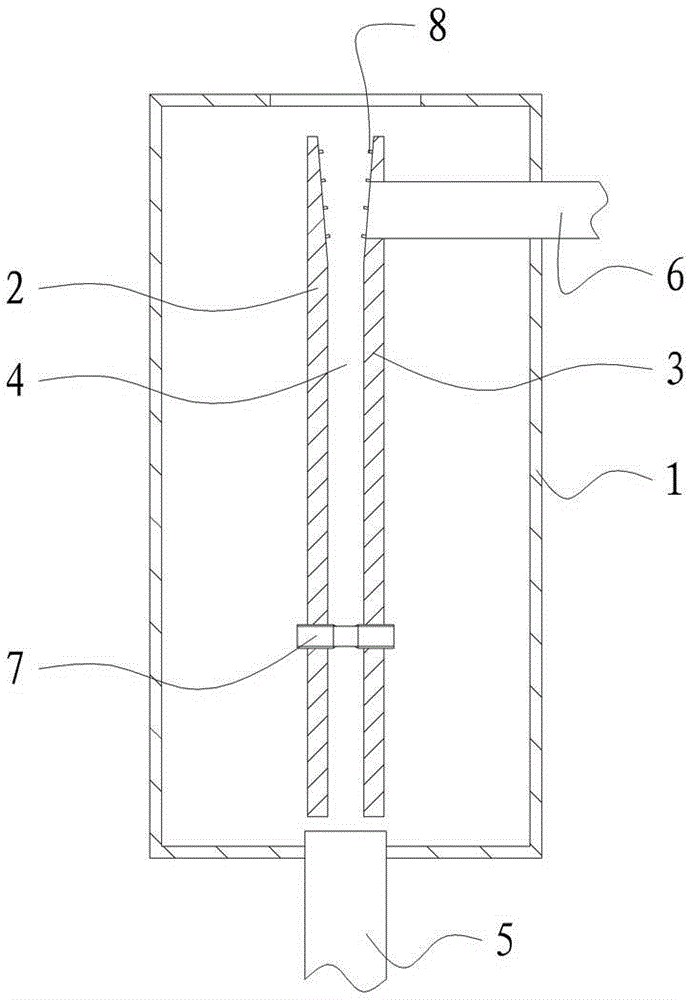

[0016] The adjustable ejector of the present embodiment, such as figure 1 As shown, it includes a jet box 1 provided with an outlet, and the jet box 1 is provided with a relative left splint 2 and a right splint 3, and a jet nozzle 4 is formed between the left splint 2 and the right splint 3, and the left splint 2 and the right splint 3 The distance is 8-20mm, the outlet end of the jet nozzle 4 is set opposite to the outlet of the jet box 1,

[0017] The inlet end of the jet nozzle 4 is provided with a jet liquid inlet pipe 5, the jet liquid inlet pipe 5 is parallel to the left splint 2 and the right splint 3, the inlet of the jet liquid inlet pipe 5 is connected with the outside of the jet box 1, and the edge of the right splint 3 is provided with a The air inlet pipe 6 connected to the outlet end of the jet nozzle 4 . Bolts 7 are perforated between the left splint 2 and the right splint 3, and the two ends of the bolts 7 are respectively screwed to the left splint 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com