Indicator lamp and light emitting device thereof

A technology for light-emitting devices and indicator lights, which is applied to electric light sources, light source fixing, and components of lighting devices, etc., can solve the problems of complicated assembly procedures, large amount of epoxy glue, and incompatibility with assembly processes, and simplify production and assembly. process, the effect of meeting the requirements of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

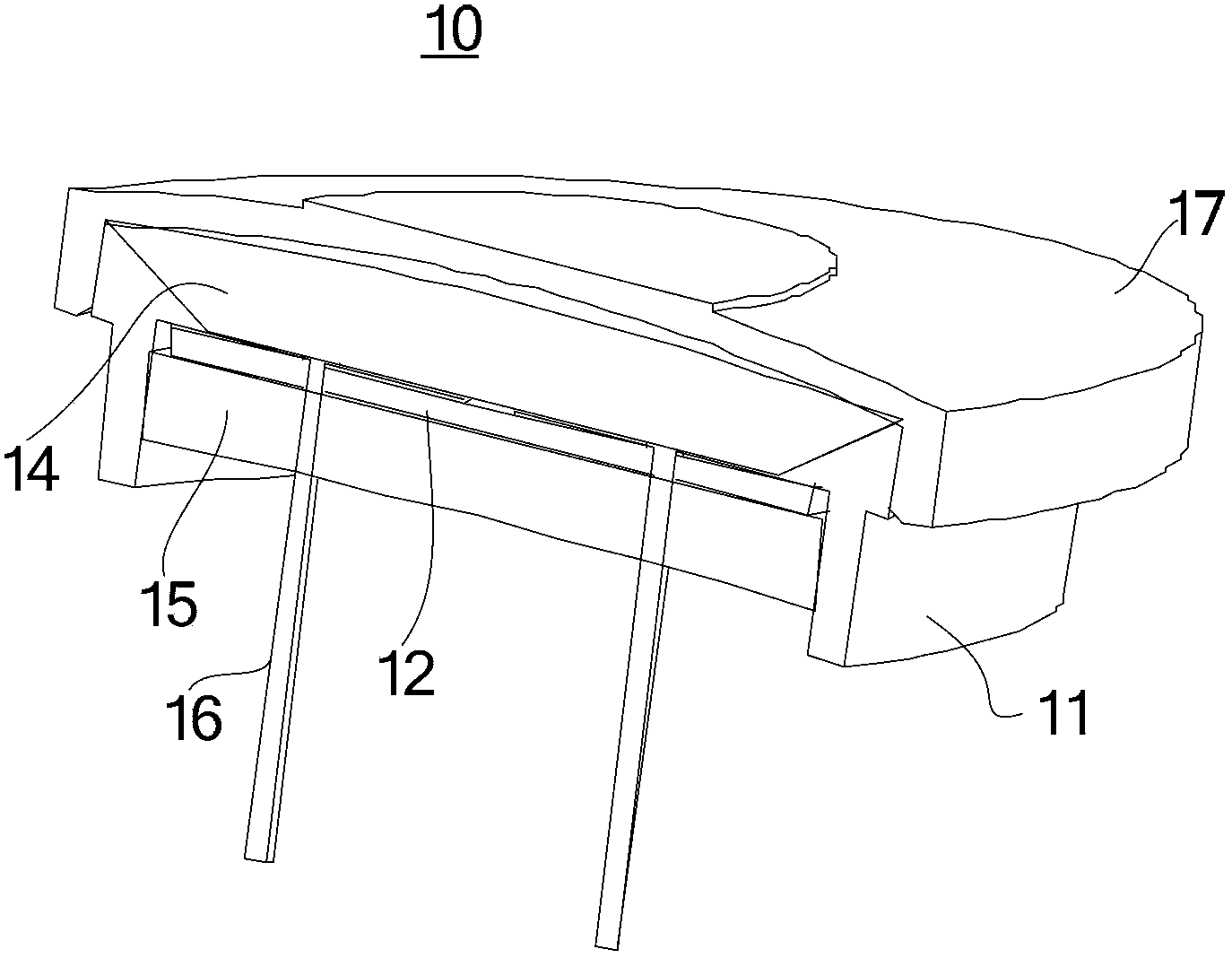

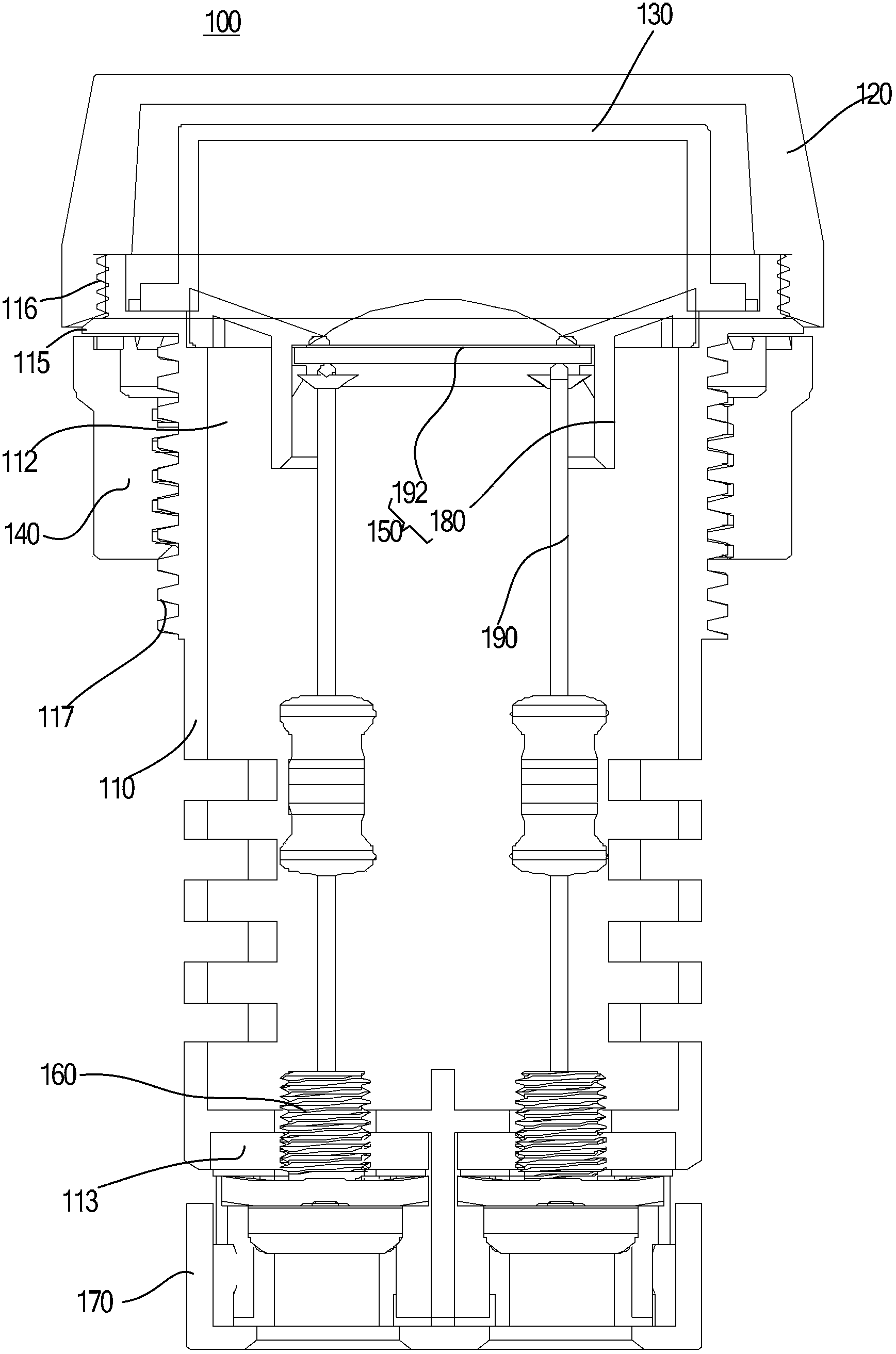

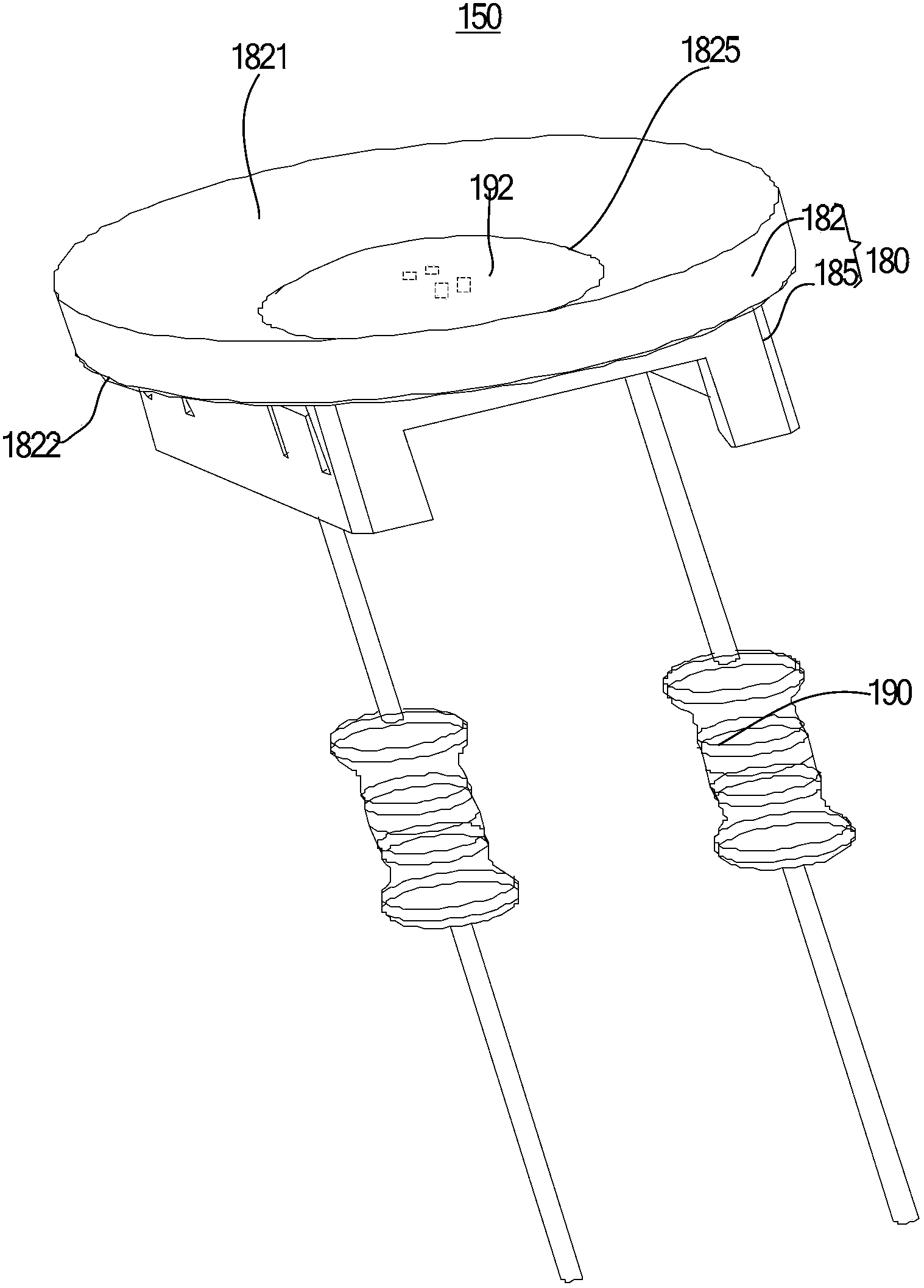

[0037] figure 2 Shown is a schematic diagram of an indicator light 100 in an embodiment of the present invention. Such as figure 2 As shown in , the indicator light 100 includes a housing 110, a lampshade 120, a lining 130, a nut 140, a light emitting device 150, at least one such as two step-down electronic components 190, two terminals 160 and a end cap 170 .

[0038] Specifically, the casing 110 is substantially cylindrical and has a first end 112 and a second end 113 . The first end 112 and the second end 113 are opposite ends of the housing 110 . A step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com