Electric vehicle jet heat pump air conditioning system and control method thereof

A heat pump air conditioner and electric vehicle technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of high power consumption, unfavorable conditions, and increase the mileage of electric vehicles, etc. Heat, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

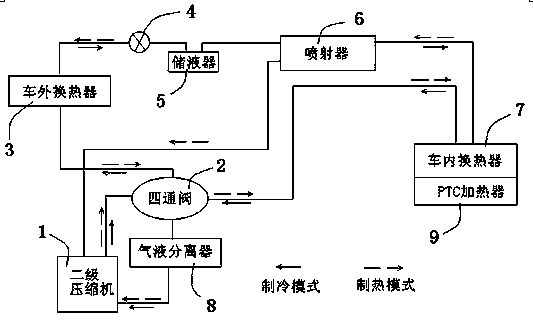

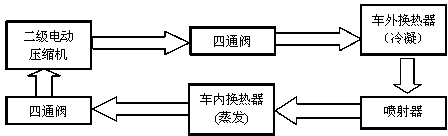

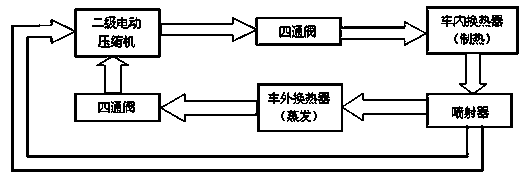

[0019] As shown in the figure, the jet heat pump air conditioning system for electric vehicles in this embodiment includes an electric secondary compressor 1, a four-way valve 2, an external heat exchanger 3, an electronic valve 4, a liquid reservoir 5, an ejector 6, and an in-vehicle Heat exchanger 7, gas-liquid separator 8; the high-pressure port of the electric secondary compressor 1 sequentially passes through the four-way valve 2, the external heat exchanger 3, the electronic valve 4, the liquid reservoir 5, and the injector 6 The main fluid inlet is connected; the medium pressure port of the electric secondary compressor 1 is connected with the injection fluid outlet of the injector 6; the low pressure port of the electric secondary compressor 1 passes through the gas-liquid separator 8 and the four-way valve in sequence 2. The interior heat exchanger 7 is connected with the main fluid outlet of the injector 6 behind.

[0020] The heat exchanger 7 in the car is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com