Chassis quick-changing battery box for electric automobile

A technology for electric vehicles and battery replacement, applied in battery pack parts, circuits, electrical components, etc., can solve the problem of low connection strength, and achieve the effect of ensuring its own strength and reducing the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

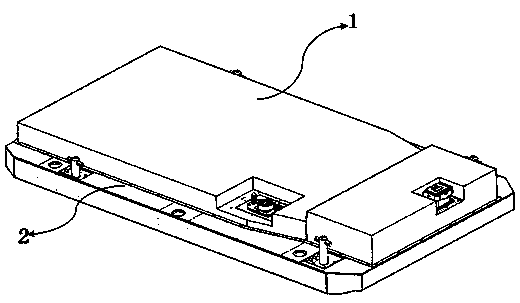

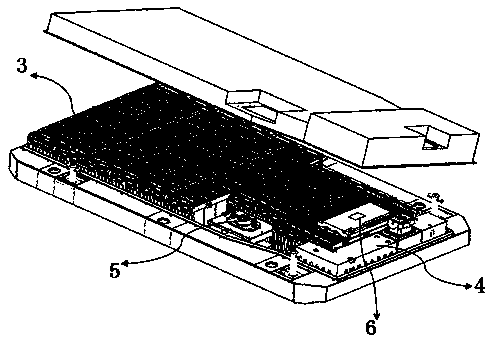

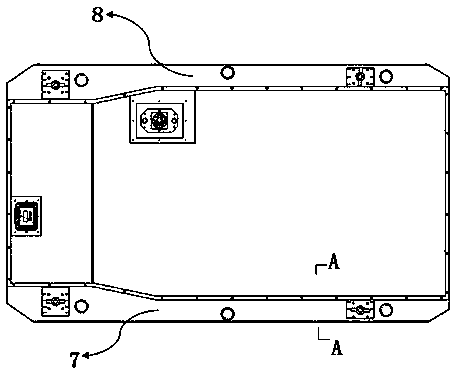

[0025] Such as Figure 1 to Figure 8 As shown, an embodiment of a chassis quick-change battery box for an electric vehicle, the battery box in this embodiment includes a box body 2 and a box cover 1, the box body 2 and the box cover 1 form a sealed space, and the box cover of the battery box is opened After 1, the battery unit that can be stored in the battery box, the battery unit includes a battery module 3, a high-voltage component 4 located at the front end, a connector plug 5 for docking with the socket at the car body end, a battery management system 6, and a heating belt etc. After the battery box is mounted on the chassis of the vehicle, the connector plug 5 on the battery box is mated with the vehicle end socket, thereby realizing the power supply to the electric vehicle.

[0026] The cover 1 of the battery box is processed by cold-rolled sheet metal bending and local tailor welding. The left and right sides of the cover 1 are respectively provided with connecting fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com