Anti-explosion junction device good for preventing electrified wrong opening

An explosion-proof wiring and accidental opening technology, applied in the direction of electrical components, etc., can solve the problems of junction box sealing failure, unfavorable safety production, live detachment of the shell, etc., and achieve the effect of preventing electric false opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

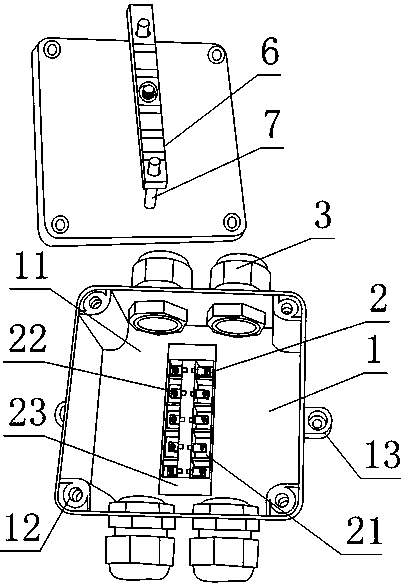

[0033] Such as Figure 1 to Figure 7 , an explosion-proof wiring device that is beneficial to prevent mis-opening when charged, includes a groove-shaped base 1 and an upper cover 4 connected with the base 1 by bolts or screws, and a wiring cavity 11 is formed between the base 1 and the upper cover 4. At least one threading pipe 3 is also fixed on the side of the base 1, and a wiring part 2 is also arranged in the wiring cavity 11, and the wiring part 2 includes an incoming line side 21, an outgoing line side 22 and a conductive strip 6. Both the incoming line side 21 and the outgoing line side 22 are provided with at least one contact 24, and the contacts 24 on the incoming line side 21 and the contacts 24 on the outgoing line side 22 are symmetrically arranged in pairs;

[0034] Also be fixed with guide bar 7 on described loam cake 4, be also provided with the screw rod 9 that becomes screw connection with it on the loam cake 4, described screw rod 9 is parallel with the axis...

Embodiment 2

[0038] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 7 , because the base 1 and the upper cover 4 are mostly made of plastic materials in the prior art, no matter for safety considerations or material saving considerations. Failure, the base 1 is fixed with a plurality of threaded seats 12 for connecting the base 1 and the upper cover 4 with bolts or screws, and the threaded seats 12 are all internal threaded metal sleeves embedded in the base 1. In this embodiment The threaded seat 12 is a copper sleeve provided with internal threads.

Embodiment 3

[0040] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 7 , in order to ensure the sealing performance between the base 1 and the upper cover 4 , a housing sealing ring is also provided between the connecting end faces of the base 1 and the upper cover 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com