Luminous module printed circuit board

A light-emitting module and circuit board technology, which is applied in the direction of circuits, circuit layout, semiconductor devices of light-emitting elements, etc., can solve problems such as design difficulties, and achieve the effects of small material consumption, good thermal conductivity, and contact prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

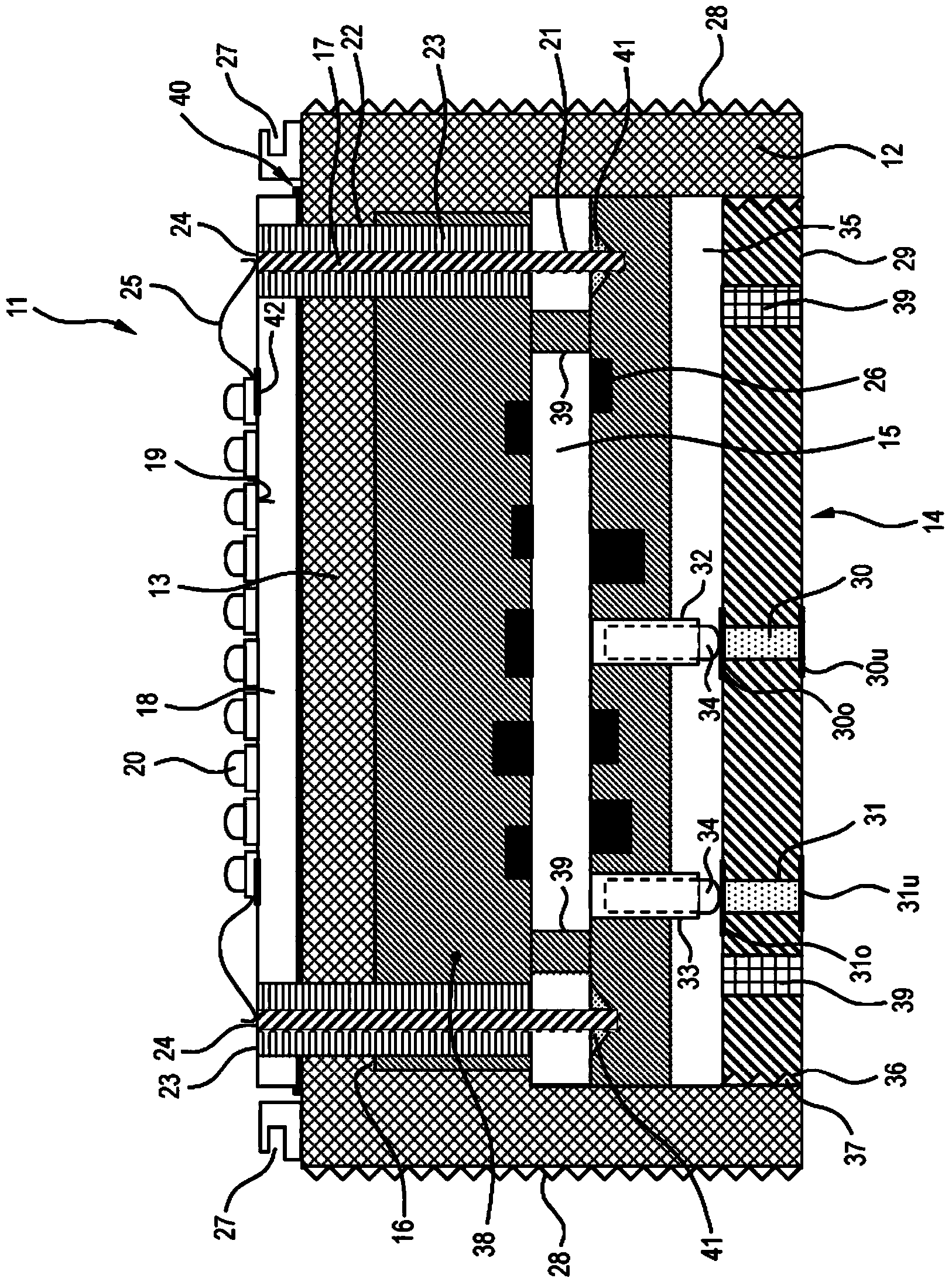

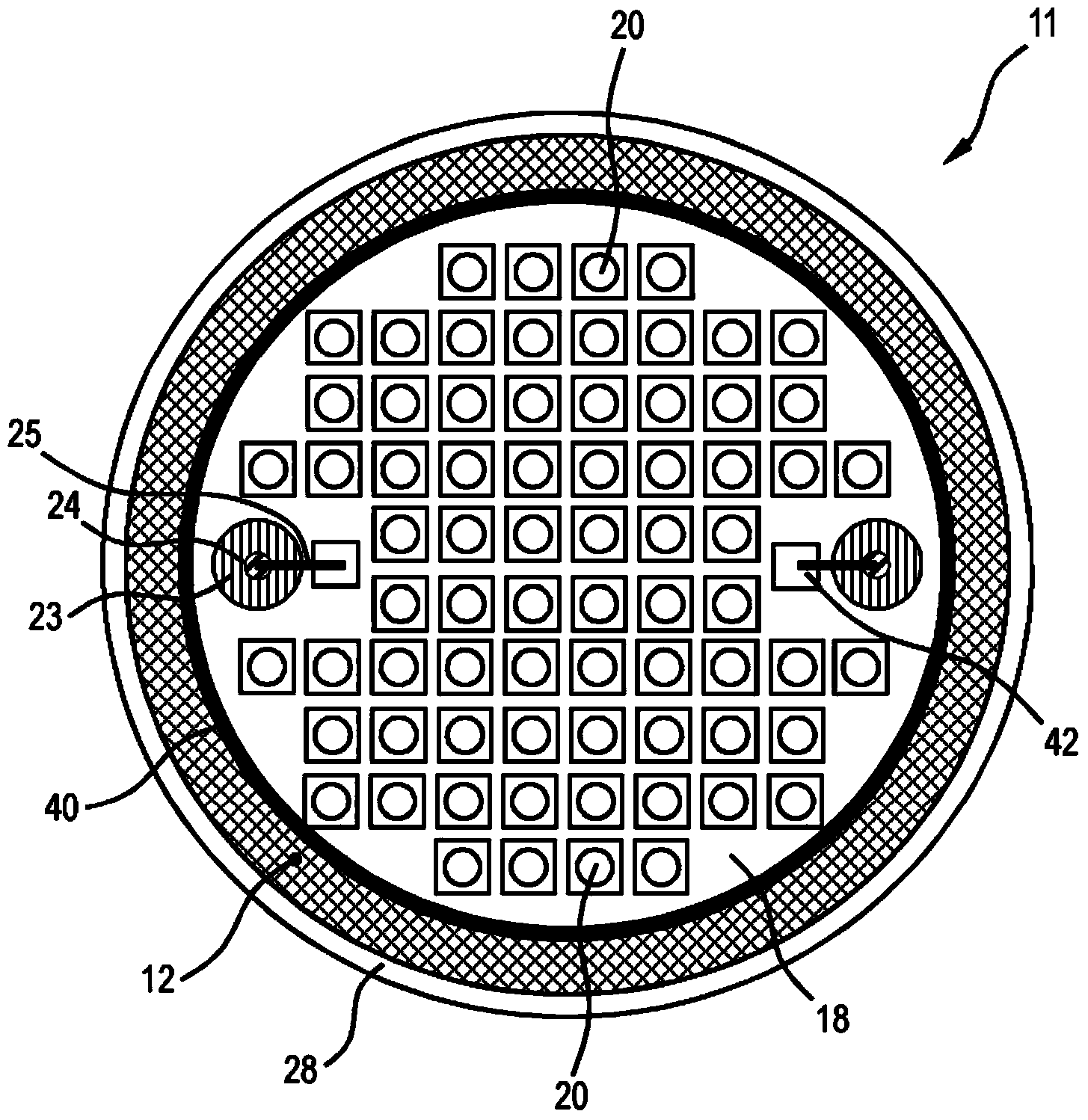

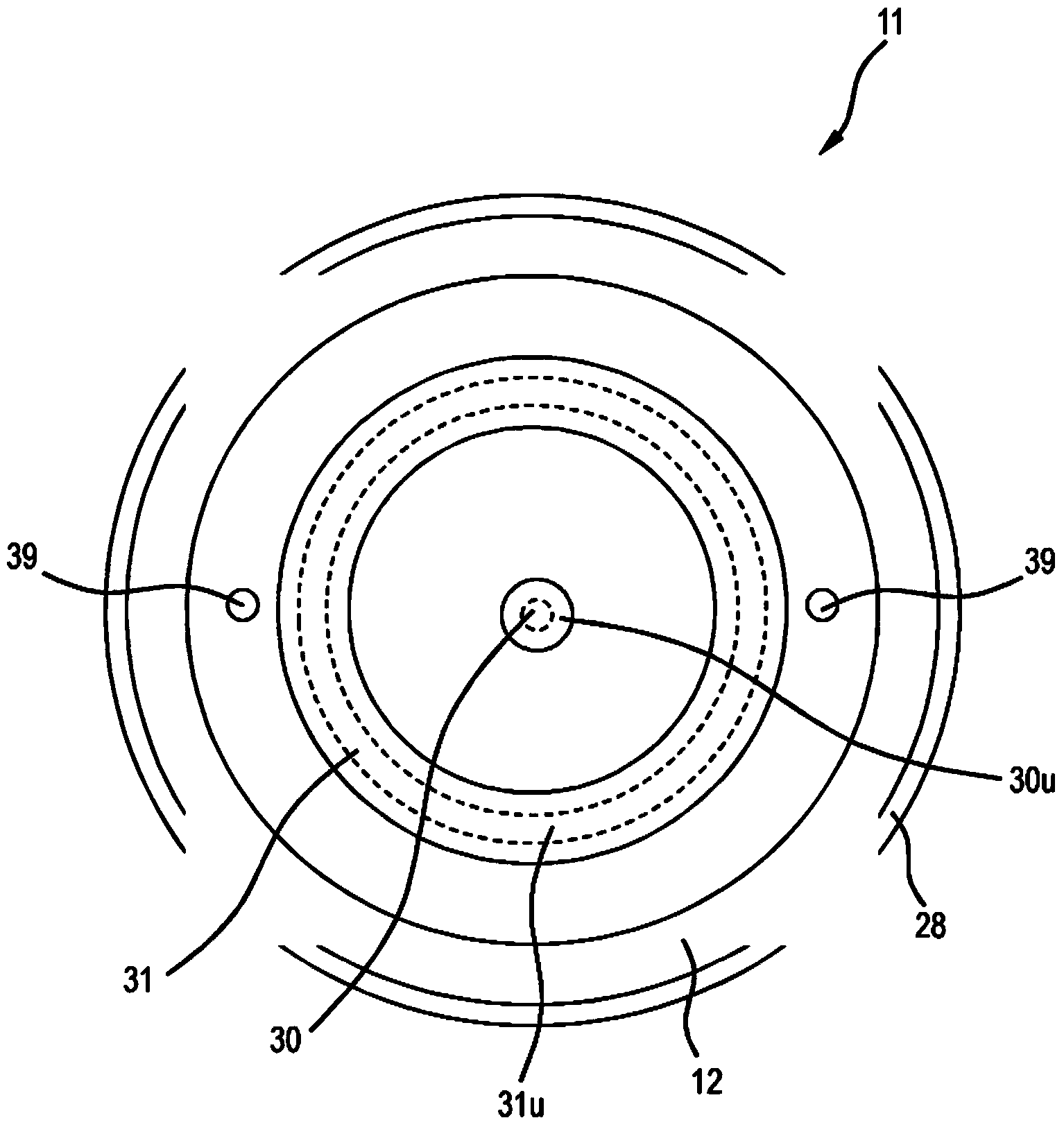

[0052] figure 1 A lighting module 11 is shown for installation in a luminaire, lighting system or the like.

[0053] The lighting module 11 has a metal housing 12 with a hollow cylindrical basic shape with a substantially closed front side 13 and an open rear side 14 . A disc-shaped lighting module circuit board 15 having CEM-3 or FR-4 as its base material is accommodated in the housing 12 . For simple and precise positioning of the light module circuit board 15 , it rests with its front outer edge on the inner projection 16 or on the taper of the housing 12 .

[0054] The lighting module circuit board 15 is electrically connected to the light source substrate 18 via two vertical, electrically conductive contact pins 17 . The light source substrate 18 is arranged outside the housing 12 , that is to say it is placed laterally with its rear side on the front side 13 of the housing 12 , here via a heat-conducting glue 40 . The free front side 19 of the light source substrate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com