Roll forming die for disposable sanitary products

A technology for sanitary products and roll forming, applied in metal processing and other directions, can solve the problems of increasing processing cost, mold loss, incomplete cutting, etc., and achieve the effects of improving coaxiality accuracy, reducing mold cost, and improving installation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

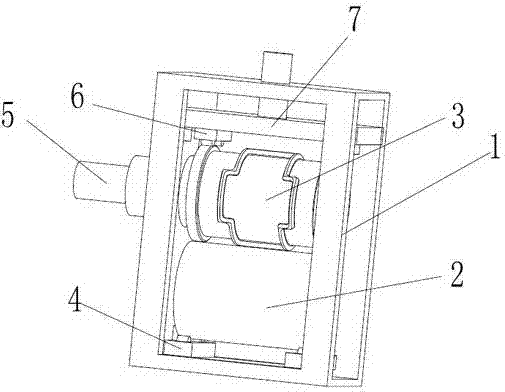

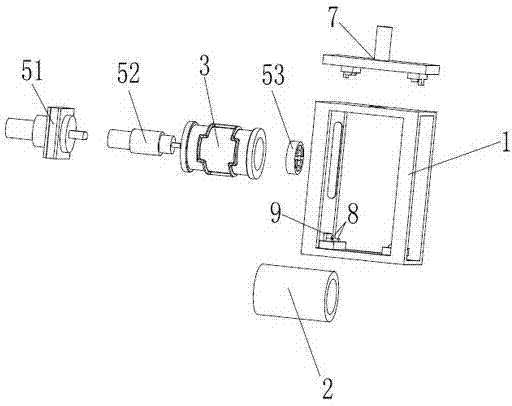

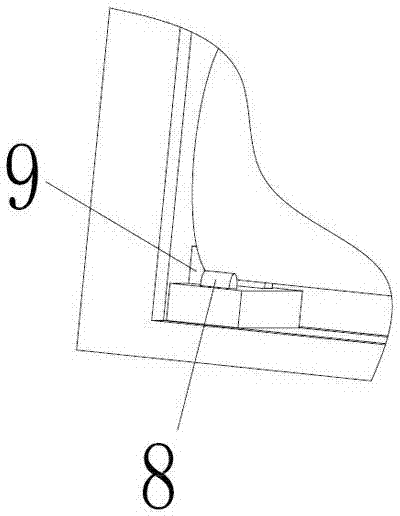

[0025] figure 1 , figure 2 , image 3 The roll forming die of the shown disposable sanitary product comprises a mold base 1, a lower roll 2 and an upper roll 3, and the lower roll 2 and the upper roll 3 are assembled and fixed on the mold base 1 in parallel, and the lower roll 2 and the upper roll 3 are fixed on the mold base 1 in parallel. The upper rollers 3 are cylinders, most preferably hollow cylinders, the lower rollers 2 are placed on the bottom of the formwork 1, and the axial position is positioned by the first positioning part 4 fixed on the bottom of the formwork 1. One side of the upper roller 3 locates the radial position of the upper roller through the driving part 5 and the formwork 1, the second positioning part 6 locates the axial position of the upper roller 3, and the second positioning part 6 is fixedly connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com